Berncarpenter

Established Member

Silverbirch":t826ua5g said:I recently bought a copy of "Wooden Planes and How To Make Them" from Axminster for just a few pounds. It has a fair bit of information on making moulding planes, among others, but only gives the briefest details on choice of timber. It`s not showing on their site now, as far as I can see, but that might just be down to their rubbish search facility. It might be worth looking for elsewhere.

Ian

Thanks Ian I will try and track that one down.

condeesteso":t826ua5g said:This looks interesting! Would you be planning a set of hollows and rounds by any chance??, Well, a half set maybe #-o

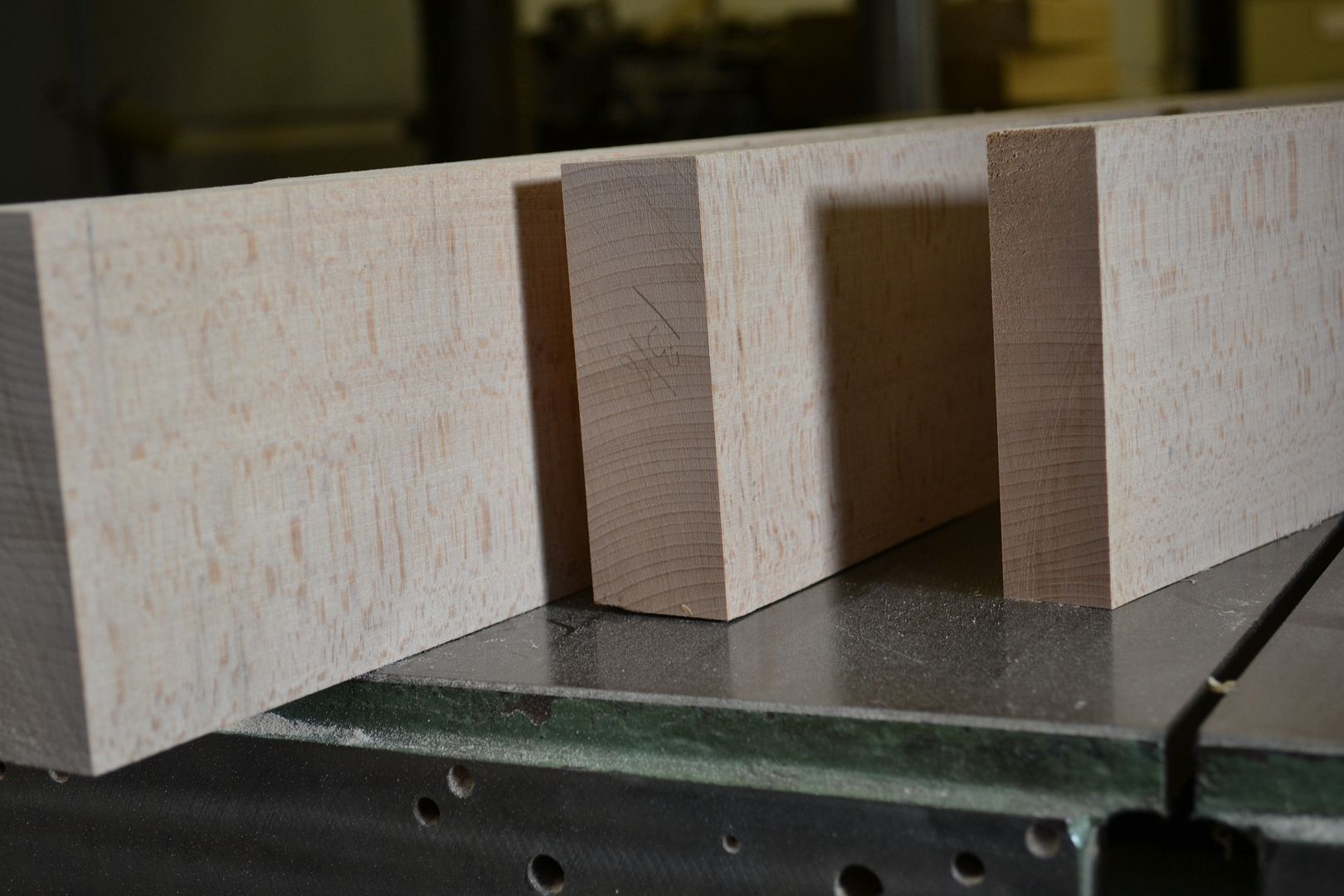

I'm no planemaker, but you have quartersawn there (top pic anyway) so likely to be nicely stable drying from 20 down to say 8-10.

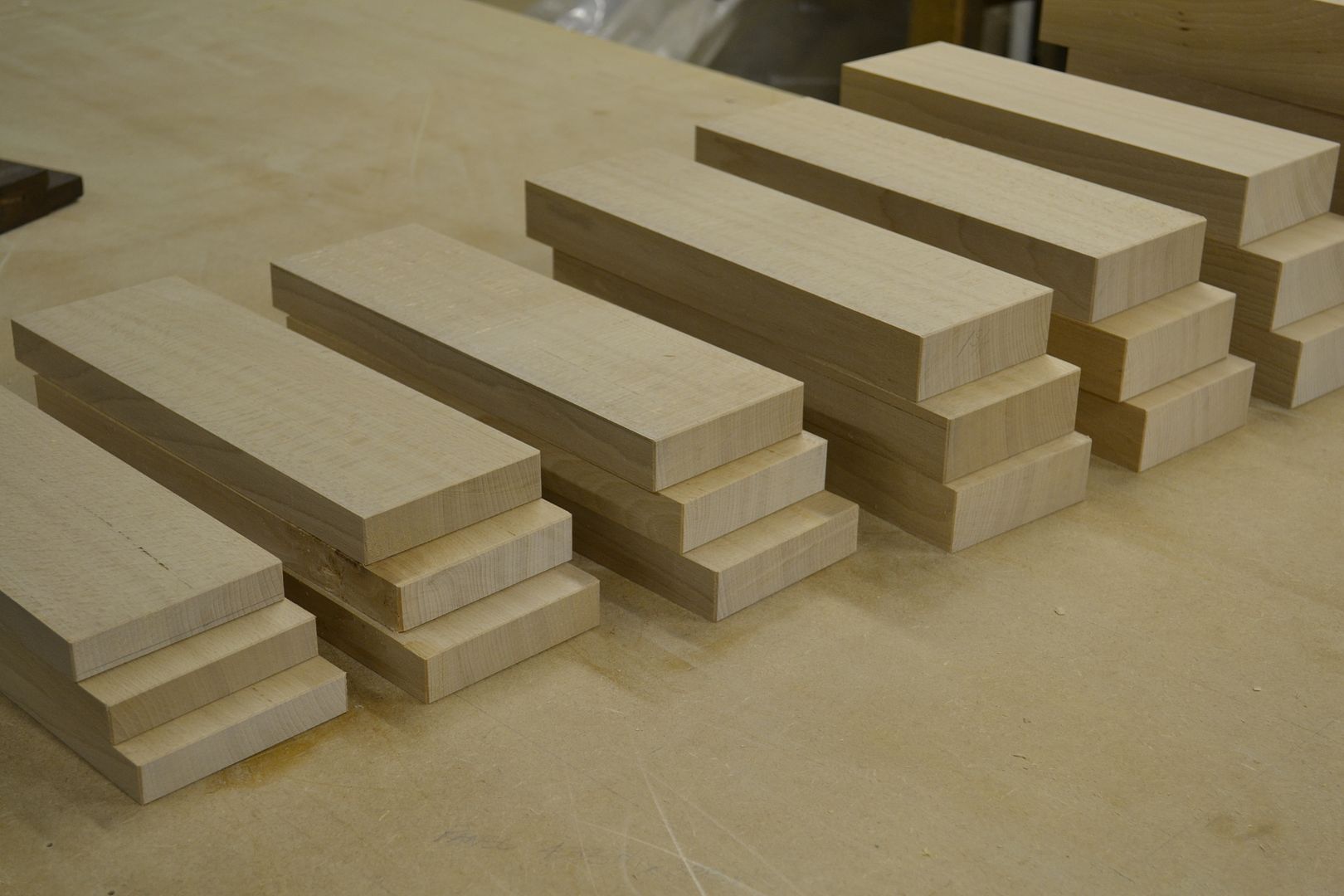

It would be safe surely to reduce this stock to smaller lumps given the intended use, maybe to short billets a little over-length and say 10 - 15mm over in thickness. Plenty of wax over ends extending an inch or so along end grain. This way it will drop in m/c far quicker whilst taking care to avoid shock-drying at all.

I've tried various stuff for end sealing but the old wax still seems the best - I just melt it in a jam jar in water then brush it on quickly. I have a load of hornbeam done that way at the moment and it's behaving very well (a new bench on the way some day soonish!).

You'll appreciate the air-dried beech - it works and handles beautifully in every direction, miles nicer than kiln-dried.

ALSO, get in touch with AndyTnT (toolsntat), he has a set of plane makers planes intended for making woodie moulding planes - he may lend them out if you ask nicely. I've seen them and they are incredible, basically a set of woodies with profiles the negative of the plane to be made, plus a specialist plane for making wedge profiles en masse... fab stuff he has!!

Keep us all posted, a fascinating exercise no doubt requiring much patience but the result would be quite something.

I was lucky to pick up an almost complete half set of hollows and rounds from a car boot sale back in the summer. Most are able to be brought into a useable condition , ive been sorting them out slowly making new wedges and truing up the bodies.

Enjoyed sorting these out but would like to make the few that are missing also some rebate and beading planes.

Getting quarter sawn beech was not easy, it seams most timber is sawn through & through and you have to search to find them centre cut boards . Gavin at Wentwood Timber was very helpful in finding just what i wanted.

I will crack on resaw and wax up . Thanks for this info it was just what I was looking for.

Hornbeam is greet timber thats going to make a very special bench 8)