mine is about 20 years old now and its still a lovely iron. I wouldn't swap it for any replacement iron.( apart from t10)

they are in fact made from single side knife blank steel. the o1 blades ive used(Clifton and hock) are no where near as nice in fact I suspect the Clifton was so bad it was faulty!

maybe its the variability of these items that causes issues. also the fact they are thin and easy to sharpen helps.

I think it's something in the alloy. I'll dig up a picture. The fact that the japanese blades with the fault will last as long as a good O1 blade covers it up, but it's lost potential.

When I tested irons, I found that the alloy was about 80% of potential edge life. As in, if you had a high speed steel alloy and it was a bit soft, it would still outlast the best of the o1 irons, but the behavior of the steel also follows the alloy a lot, so things can get in the way of getting the most out of anything more complicated than water hardening steel (that being the least picky about ideal planing conditions).

water hardening steel (ward) lasted about 75% of 01 (blue steel is a lot like o1, but the laminated irons at higher hardness should have slightly better edge life than a decent western hardness O1 iron - maybe close to A2), O1 was about 80% of A2 (but far better at producing a finished surface in less than ideal conditions - close to water hardening) and then M2 was about 40% longer lasting than O1 and V11 (which is a carpenter stainless alloy) was about 25% longer lasting than M2 - or double that of the japanese and O1 irons and surprisingly left a much brighter surface.

The non-powder metal alloyed blades generally failed the least uniformly, but it didn't seem to affect their edge life vs. older charts I've seen that a controlled japanese test produced.

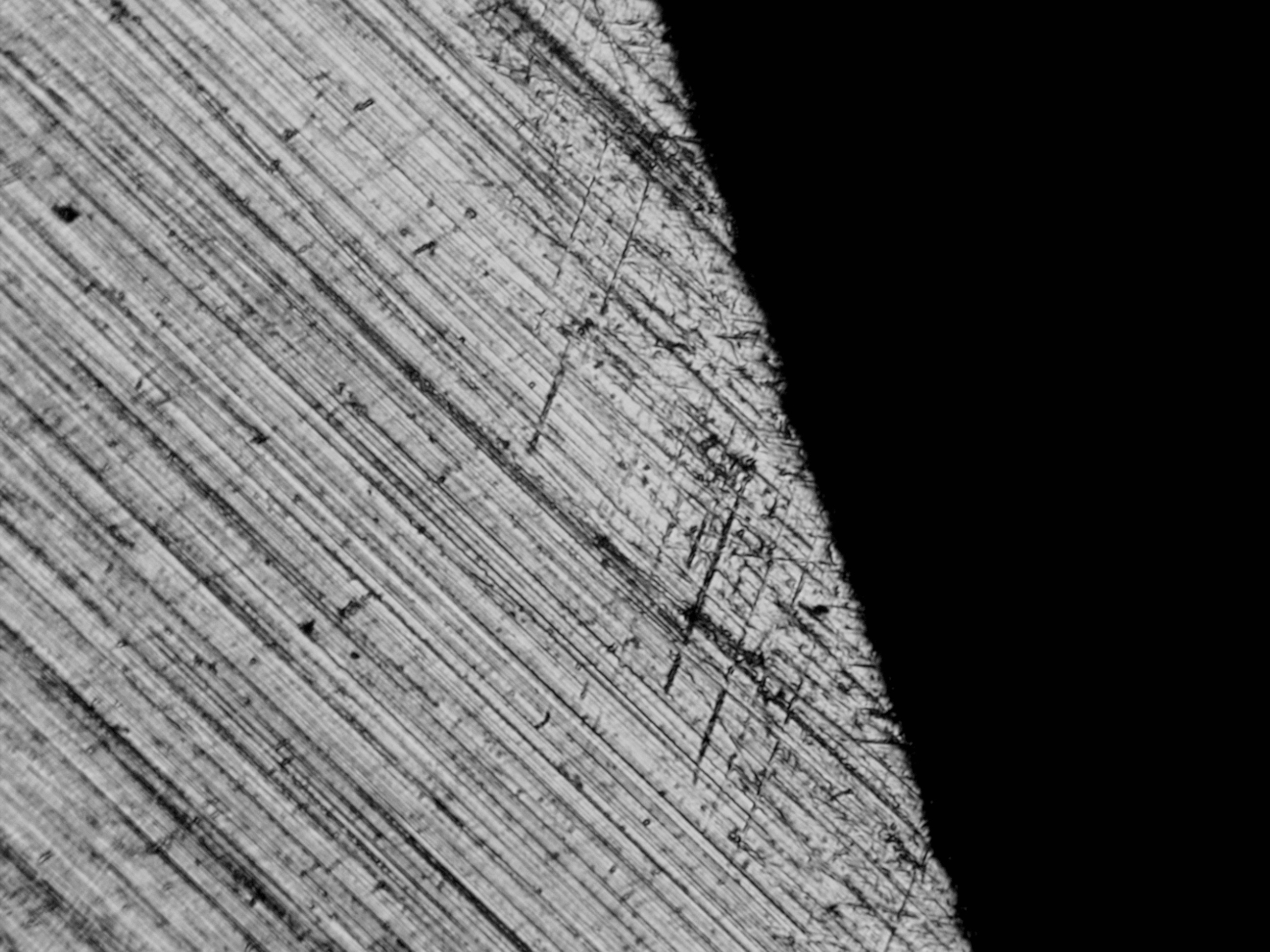

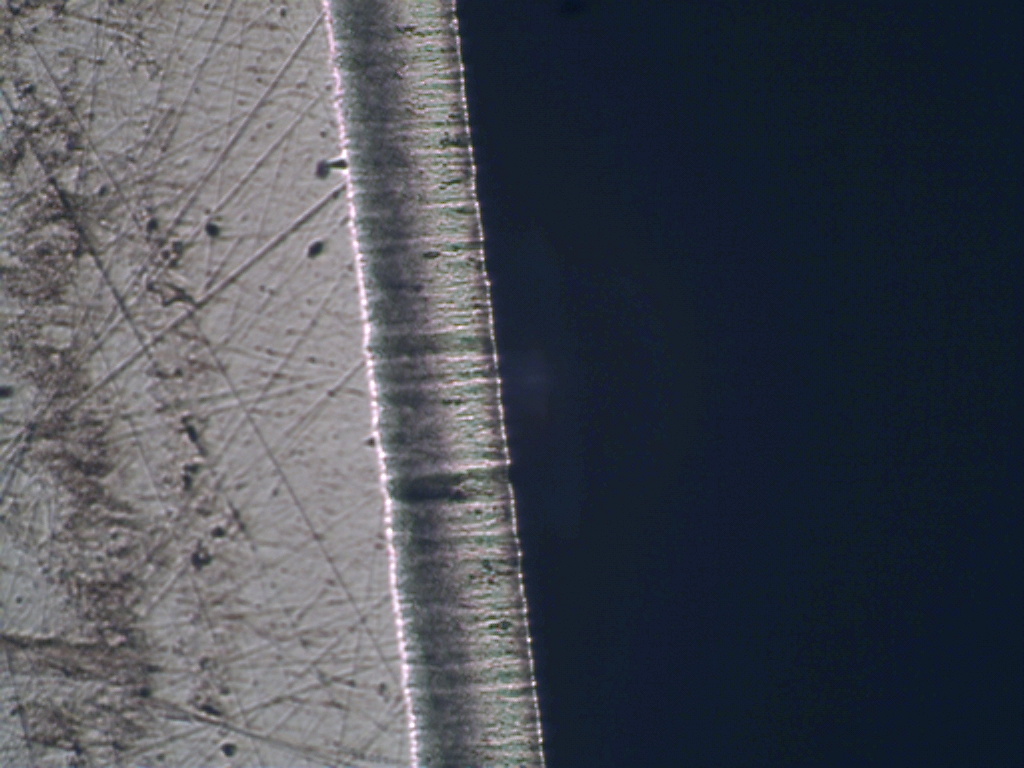

The japanese iron with its odd pock marks:

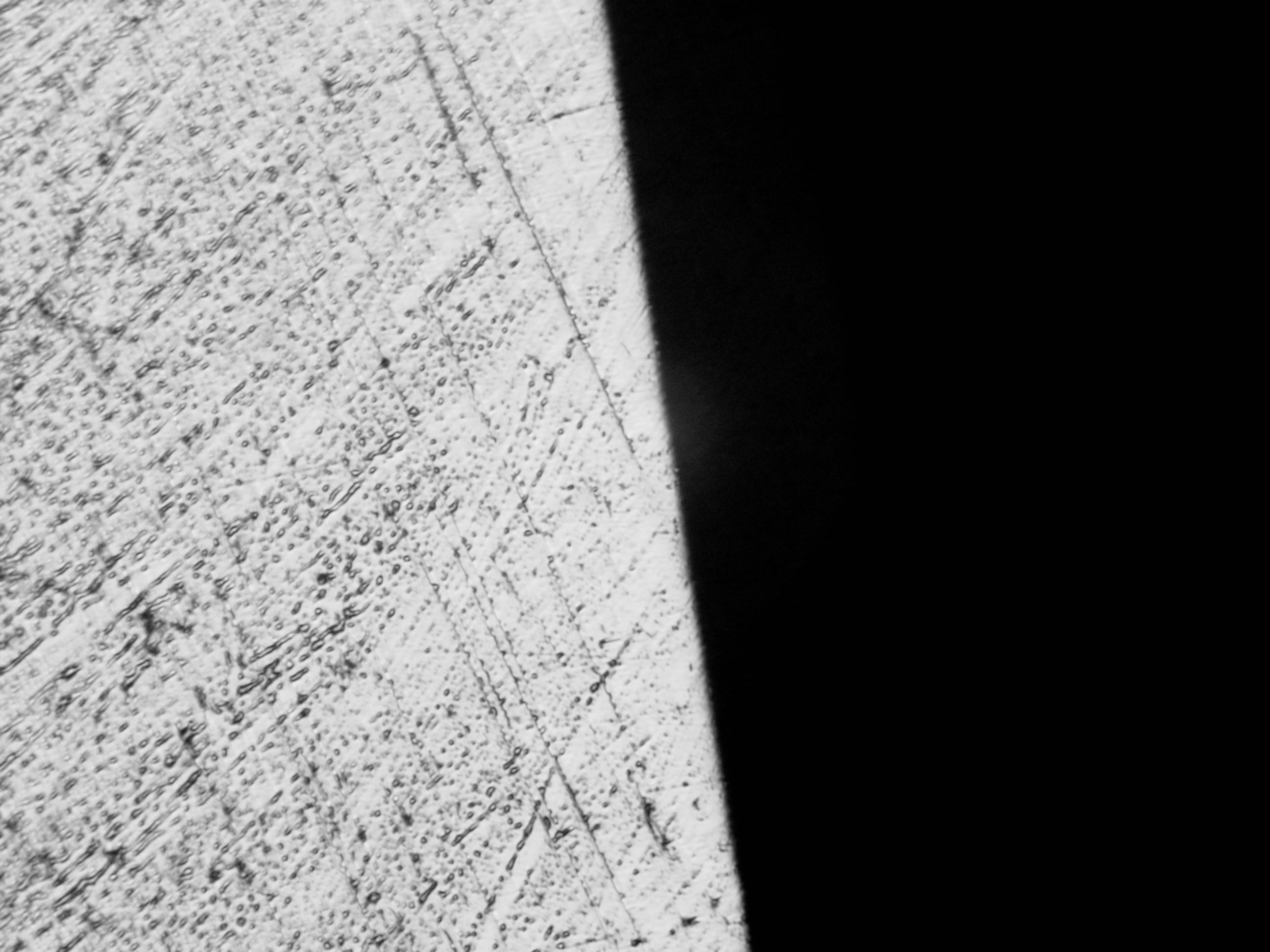

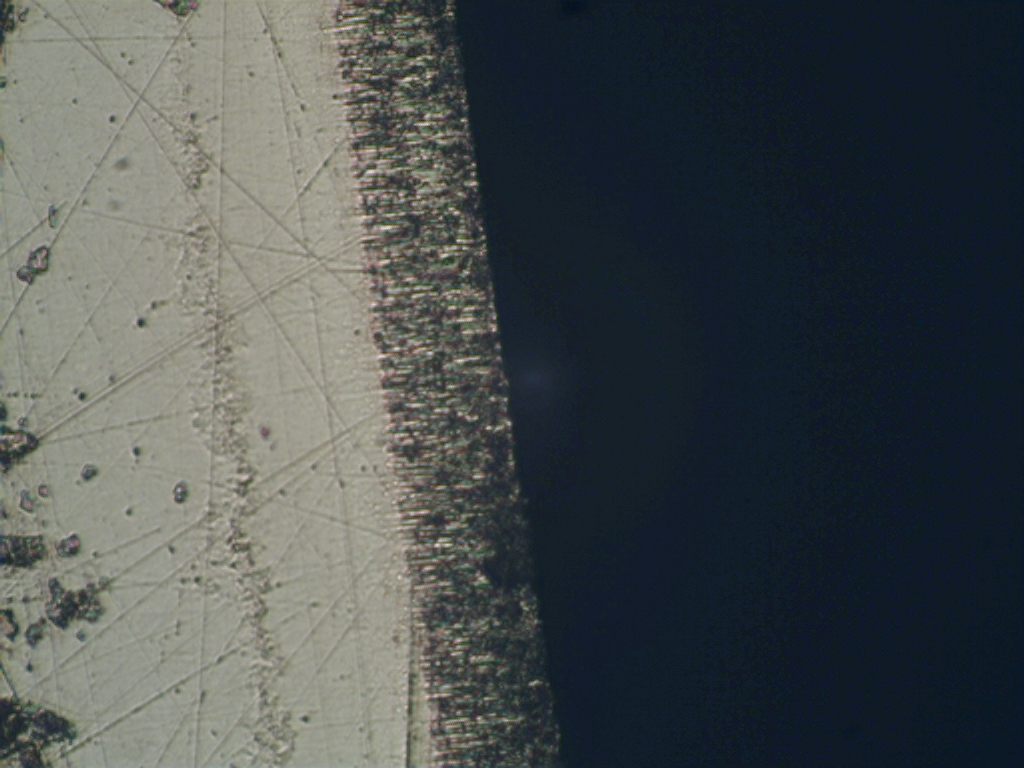

O1

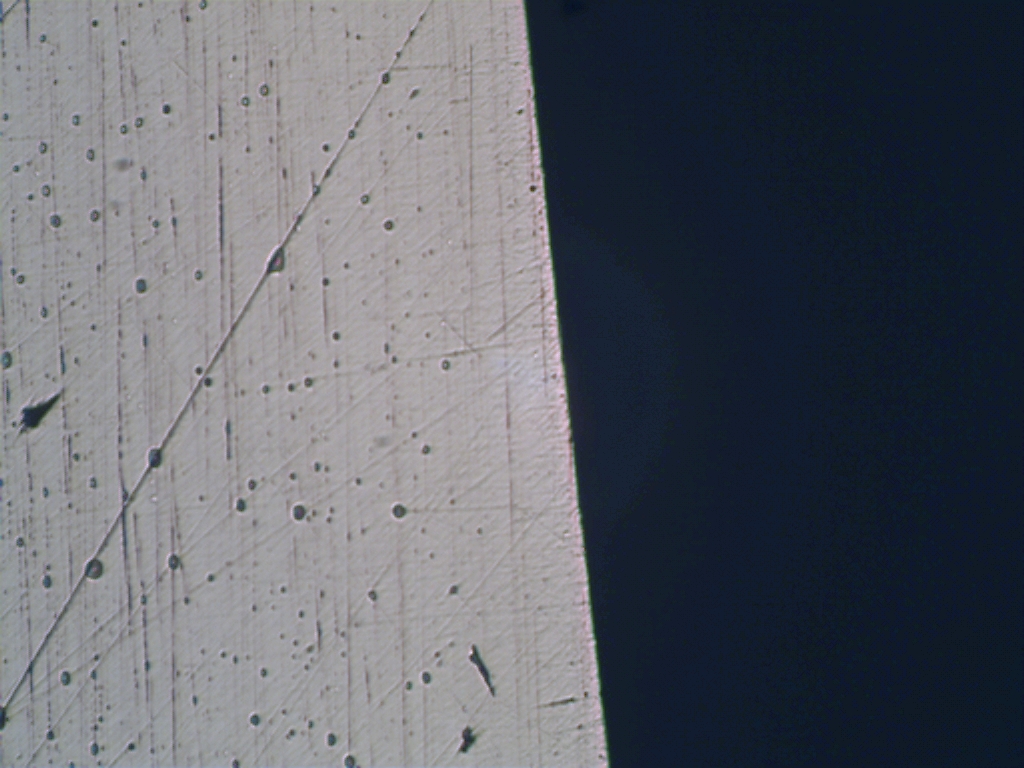

chinese HSS:

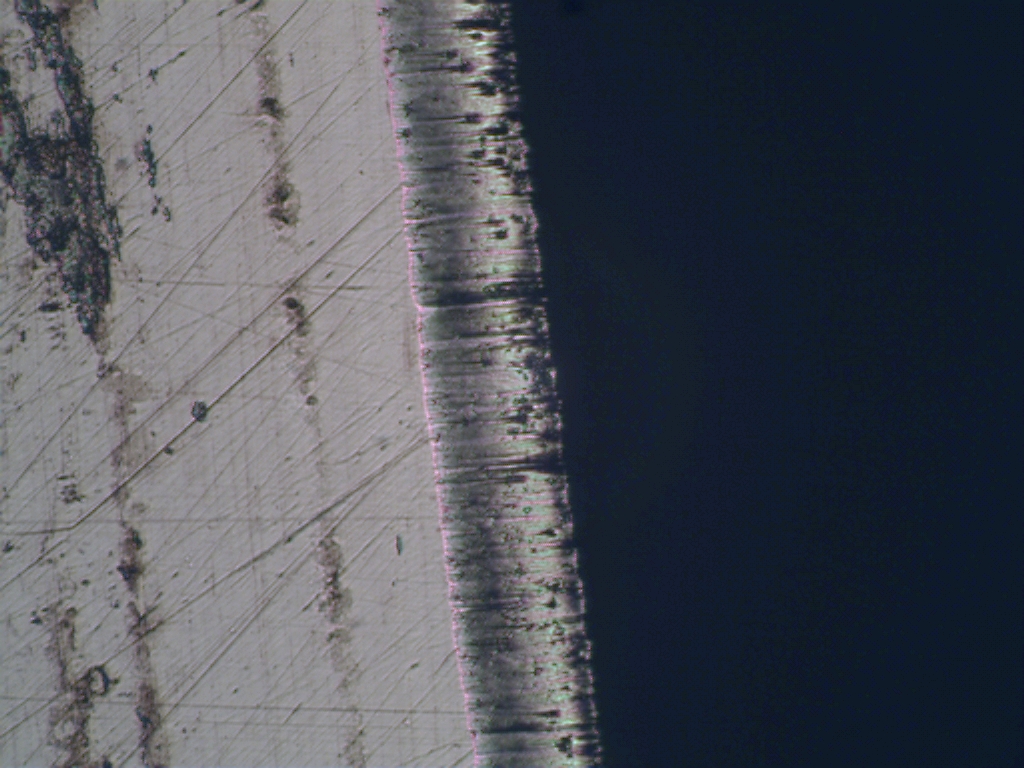

A2:

notice the dark spots on the A2 - for some reason, A2 goes along fine for a while and then seemingly starts to shed its polish. This is the second time I've tested A2 irons a decade apart and several brands - they all do this. poor quality irons chip earlier.

V11 was the clear winner in my test, but it was an ideal test in clean wood and I don't think the gap is nearly as large in rough wood or wood with any dirt in it - plus, it hones half as fast, and will probably result in the same issue that A2 has - A2 has a reputation for being chippy, but most of the chipping is due to the fact that it hones about half as fast (as does v11) as A2 and the average person will think they've honed all of the defects out of it honing 25 or 50% longer than they would with O1, but they'll have left defects.

The blue and O1 irons hone faster and part of their reputation as being easier to get a finished surface off of is probably just because they hone fast enough for the average person to remove the damage they can see as well as the damage they can't see.