And lots of questions.

Goal:

I thought I'd do a quick post of what i've done so far, so i can ask my first question.

I chose beech for the legs so cut a piece from a board, which has been seasoning in the house a good few months:

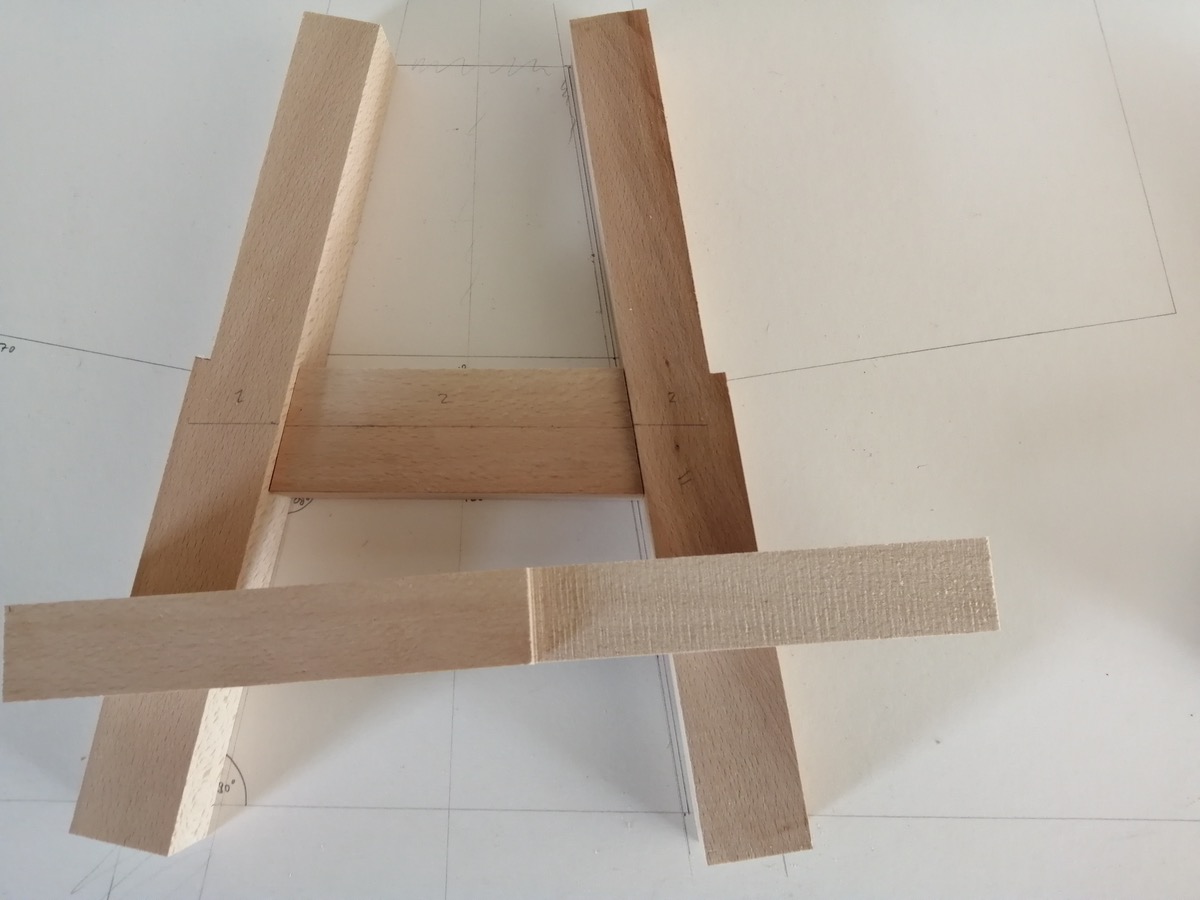

Cut pieces for the legs on the bandsaw:

Cut the cross pieces and rough angles:

Then planed to approx sizes:

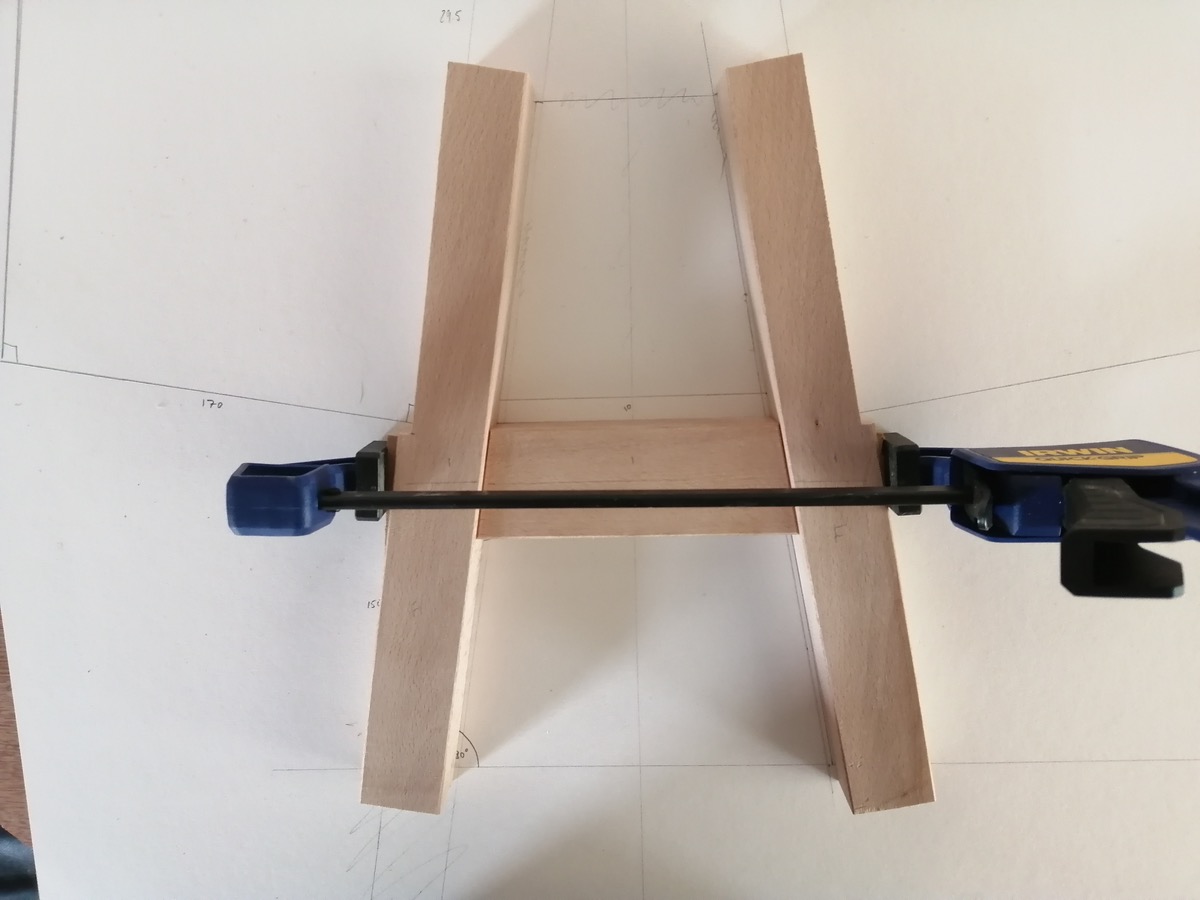

I'll be joining them with dowels.

The one on the right is about 1mm off the one on the left on account of the angle, but I find trying to plane end grain tricky at the best of times and I think if I try any more I'm going to start losing fit to the upright, creating a non-flat surface. And hopefully it's close enough. More work to do on the legs, which'll follow.

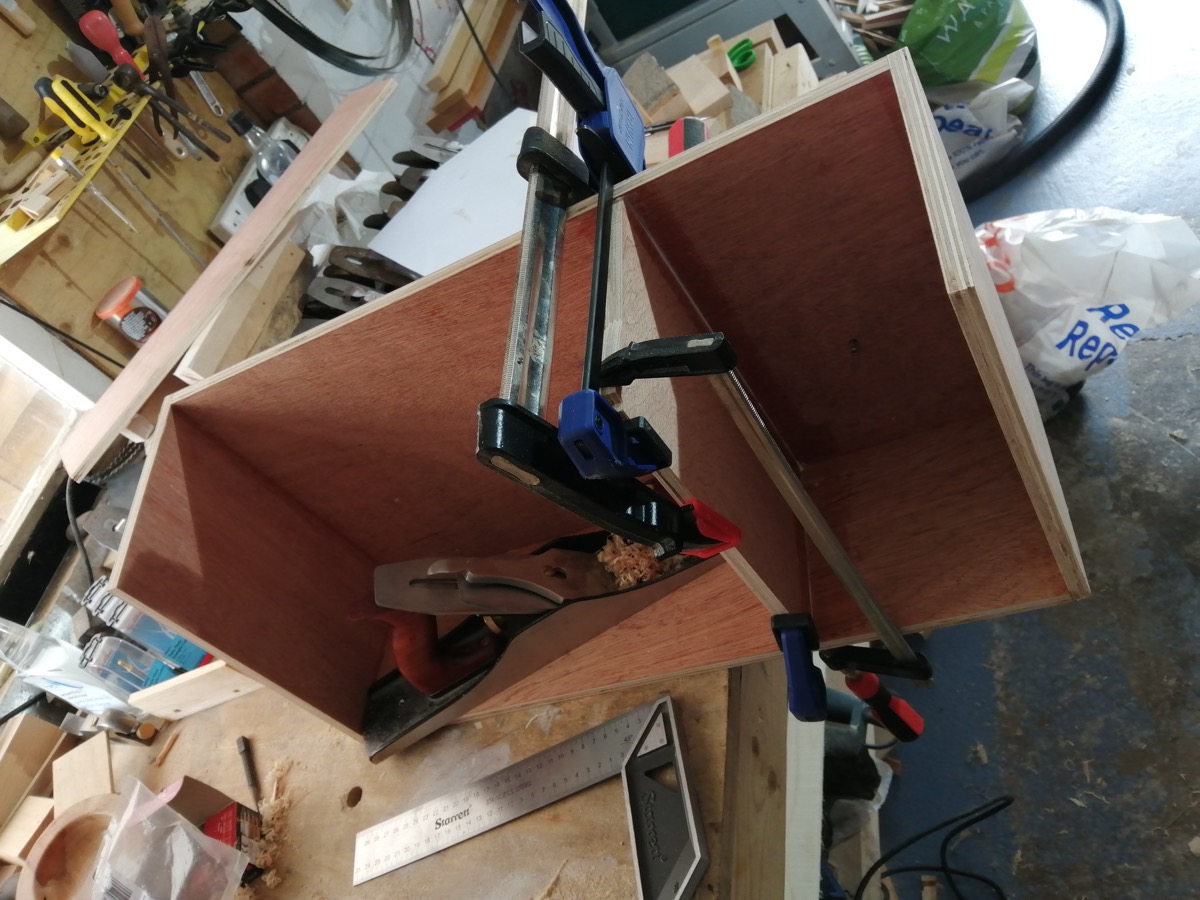

But - thinking ahead, what's the easiest/ most silly person-proof way to build boxes from 12mm ply? Would it be terribly wrong to go for butt joints, glued, tacked and filled?

ps Just noticed the one on the left is out of alignment with the drawing it sits on - it actually fits properly but I forgot to line it up properly for the pic. It's the one on the right that's out in relation to the drawing, by about 1-2mm at the bottom of the right leg.

Goal:

I thought I'd do a quick post of what i've done so far, so i can ask my first question.

I chose beech for the legs so cut a piece from a board, which has been seasoning in the house a good few months:

Cut pieces for the legs on the bandsaw:

Cut the cross pieces and rough angles:

Then planed to approx sizes:

I'll be joining them with dowels.

The one on the right is about 1mm off the one on the left on account of the angle, but I find trying to plane end grain tricky at the best of times and I think if I try any more I'm going to start losing fit to the upright, creating a non-flat surface. And hopefully it's close enough. More work to do on the legs, which'll follow.

But - thinking ahead, what's the easiest/ most silly person-proof way to build boxes from 12mm ply? Would it be terribly wrong to go for butt joints, glued, tacked and filled?

ps Just noticed the one on the left is out of alignment with the drawing it sits on - it actually fits properly but I forgot to line it up properly for the pic. It's the one on the right that's out in relation to the drawing, by about 1-2mm at the bottom of the right leg.