devonwoody

Established Member

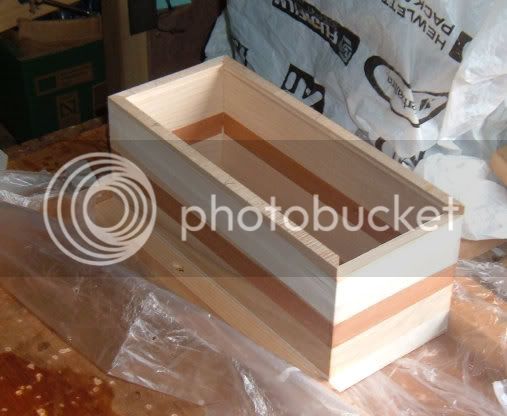

A glorious start to a new project, and a pencil box gift requested by an art member friend of mine.

window open.

temp.15C and humidity below 70% ( season can stay like that till Nov.with pleasure)

I had cut off a 4x3" length of sycamore, previous week, and now taken off a section for a pencil box, leaving a long enough piece for tissue boxes to come later.

Set the planer to give me a second square edge (The timber came one surface clean)

came off the planer square and flat.

Over to the bandsaw and put a clamp to secure my fence, because a 4x3 can push my lightweight fence around.

However my good mood is now on the wane after the clean up of the bandsaw cut and the timber going through the thicknesser.

It doesnt look very nice does it?

On top of that poor start and the second piece cut and I get this.

So I clamped the pieces together and put some pressure on them for the rest of the day.

I paid over £38 per cu.ft for that sycamore and it looks like the first 250mm is rubbish. Do you think I should request a discount and credit from the supplier.

window open.

temp.15C and humidity below 70% ( season can stay like that till Nov.with pleasure)

I had cut off a 4x3" length of sycamore, previous week, and now taken off a section for a pencil box, leaving a long enough piece for tissue boxes to come later.

Set the planer to give me a second square edge (The timber came one surface clean)

came off the planer square and flat.

Over to the bandsaw and put a clamp to secure my fence, because a 4x3 can push my lightweight fence around.

However my good mood is now on the wane after the clean up of the bandsaw cut and the timber going through the thicknesser.

It doesnt look very nice does it?

On top of that poor start and the second piece cut and I get this.

So I clamped the pieces together and put some pressure on them for the rest of the day.

I paid over £38 per cu.ft for that sycamore and it looks like the first 250mm is rubbish. Do you think I should request a discount and credit from the supplier.