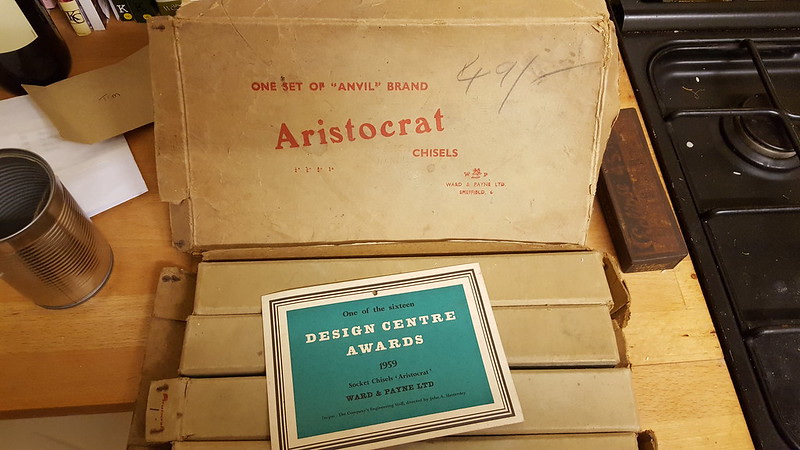

I was intrigued by these unusual chisels when I first saw them mentioned on his forum many moons ago and, when a set came up on ebay last week, I bought them thinking it would be interesting to compare these "premium" models to my motley collection of old chisels. Coincidentally another set were advertised around the same time (this time including the original boxes) and were discussed here the day after I bought mine:

http://www.ukworkshop.co.uk/forums/aristocrat-chisels-or-not-t23503-30.html

They were pricey - nearly 20 quid each if you include postage - but based on the nearly intact Ward and Pane Transfers I was hoping they would be little used.

Here are some observations and some possibly daft questions.

First of I was lucky and they seem to be hardly used - in fact the 1’’ and ¾’’ look like they still have the original ground bevel. The other two had been honed at least once:

Flatness of the face

(look away now if you are upset by chisel flattening!)

Are these chisels any flatter than your standard old Sheffield chisel - no, I don’t thinks so. It took about 3 hours to get them flatish - the two largest sizes both had a pretty deep dip on the right hand edge and I ran out of patience before I could remove the dips entirely. Here is a work in progress and the end result:

Shape

Lord knows why I need three 1’’ chisels when I do no proper woodworking, but it at least does allow a comparison. The other two below are both Marples - the paring chisel in addition to narrowing in thickness between the heel and the toe, also tapers slightly in width so it is slightly wider at the tip. The Aristocrat tapers the other way - I wonder if this is a feature or just a result of manufacturing variability back in the 60s?

The shape is like a firmer but rather than having sides at 90 degrees the sides form a bevel at 75 degrees from the face - very different from the other bevel edge chisels I have.

Does anyone know if this shape is used by other manufacturers, or why it was not as popular as the commonly found firmer shapes?

I will sharpen them tomorrow and let you know about the patented handle so we can decide on whether it is a gimmick or not.

http://www.ukworkshop.co.uk/forums/aristocrat-chisels-or-not-t23503-30.html

They were pricey - nearly 20 quid each if you include postage - but based on the nearly intact Ward and Pane Transfers I was hoping they would be little used.

Here are some observations and some possibly daft questions.

First of I was lucky and they seem to be hardly used - in fact the 1’’ and ¾’’ look like they still have the original ground bevel. The other two had been honed at least once:

Flatness of the face

(look away now if you are upset by chisel flattening!)

Are these chisels any flatter than your standard old Sheffield chisel - no, I don’t thinks so. It took about 3 hours to get them flatish - the two largest sizes both had a pretty deep dip on the right hand edge and I ran out of patience before I could remove the dips entirely. Here is a work in progress and the end result:

Shape

Lord knows why I need three 1’’ chisels when I do no proper woodworking, but it at least does allow a comparison. The other two below are both Marples - the paring chisel in addition to narrowing in thickness between the heel and the toe, also tapers slightly in width so it is slightly wider at the tip. The Aristocrat tapers the other way - I wonder if this is a feature or just a result of manufacturing variability back in the 60s?

The shape is like a firmer but rather than having sides at 90 degrees the sides form a bevel at 75 degrees from the face - very different from the other bevel edge chisels I have.

Does anyone know if this shape is used by other manufacturers, or why it was not as popular as the commonly found firmer shapes?

I will sharpen them tomorrow and let you know about the patented handle so we can decide on whether it is a gimmick or not.