You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Miniature Traction Engine

- Thread starter Nigel Taylor

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Nigel Taylor

Established Member

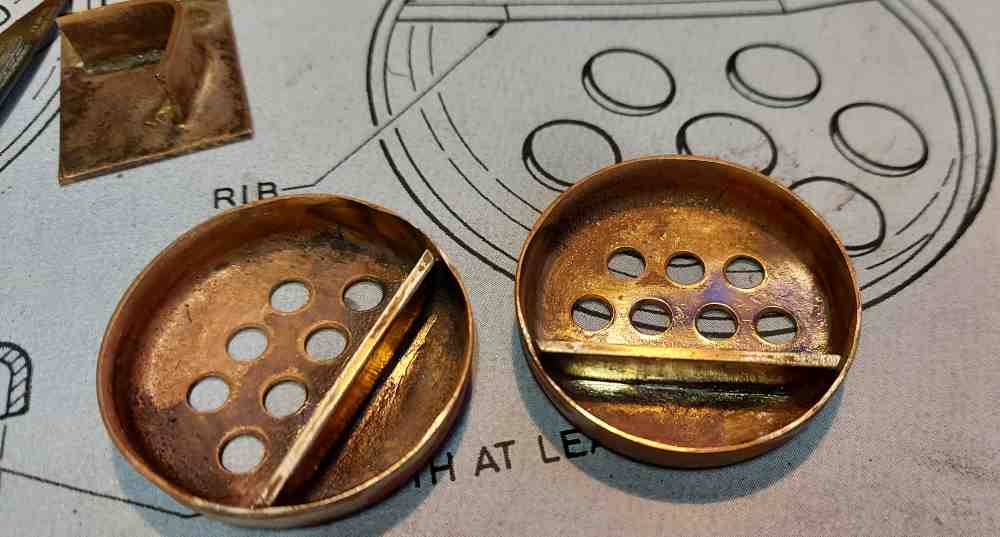

Machining the double eccentric yesterday afternoon was quite fun. I was prepared for this to be a prototype, but I think it has turned out ok.

Nigel Taylor

Established Member

Thanks, I try to share as much as I can, sometimes though I think people will be bored watching me make something.Amazing skill and very interesting to see how you have solved problems along the way. It is beautiful!

I never get bored watching things like this, I love mechanical things. You can see how they work and what's going on as the parts move round. I enjoy hearing your thought process as you build the model.I think people will be bored watching me make something.

Never! Keep up the good work.Thanks, I try to share as much as I can, sometimes though I think people will be bored watching me make something.

ecokestove

Established Member

I am in awe of people who can do this sort of work.

Nigel Taylor

Established Member

After a lot of help from a fellow steam model engineer I've managed to make and silver solder the boiler end plate stiffeners in place.

I think I'm a gluten for punishment pursuing the silver soldering in a kiln. The Easy Flo 24 did not flow as well as some of the lower temperature silver solders.

I think I'm a gluten for punishment pursuing the silver soldering in a kiln. The Easy Flo 24 did not flow as well as some of the lower temperature silver solders.

DrPhill

Cyber Heretic

Incredible work. I have been following with great interest. I can see how you have done things, that is an education in itself.

Nigel Taylor

Established Member

Back to testing the insulation for the boiler. A quick overview of the object in this short video:

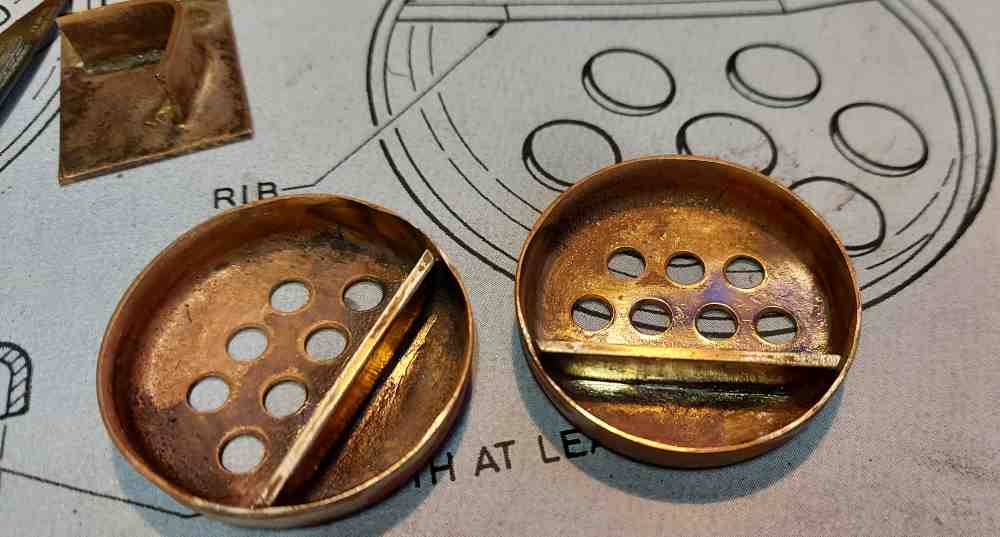

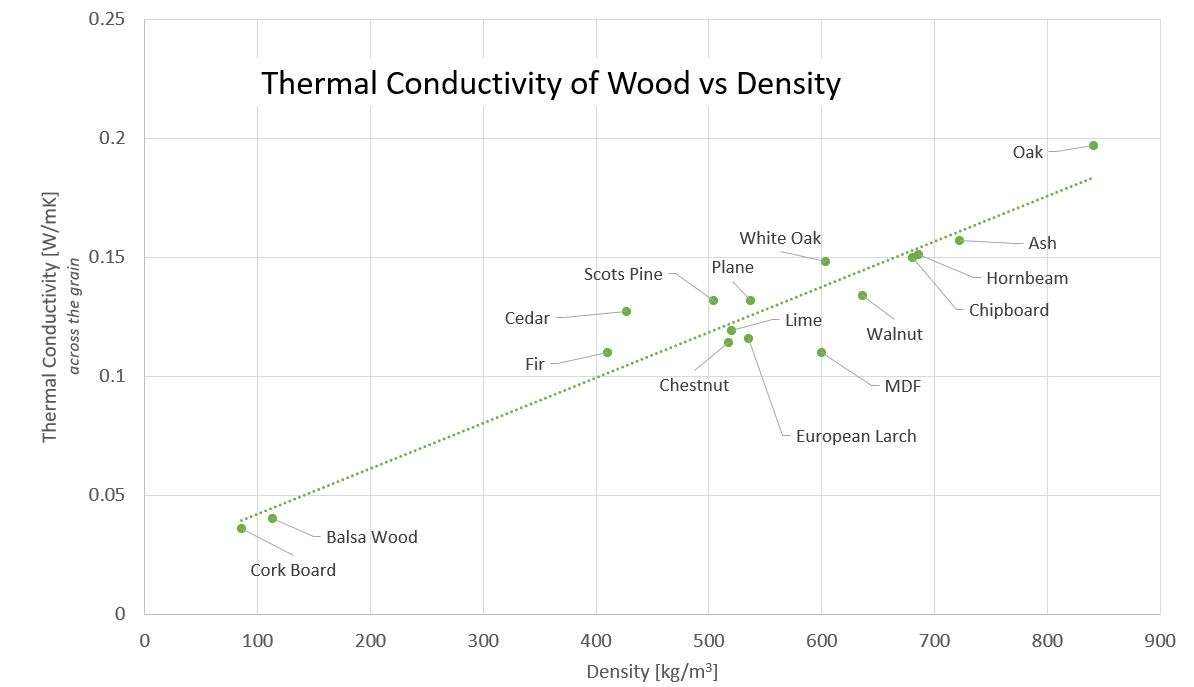

The thermal conductivity of wood versus density is an interesting plot and hence shows why I have used balsa wood as the pads.

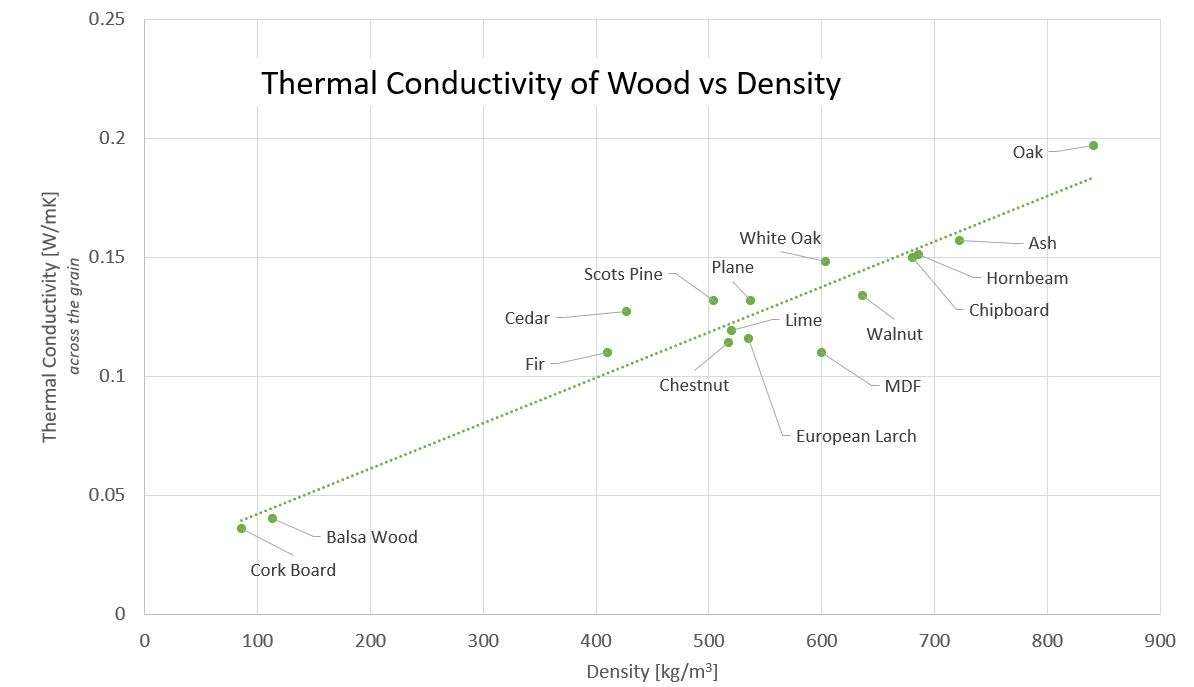

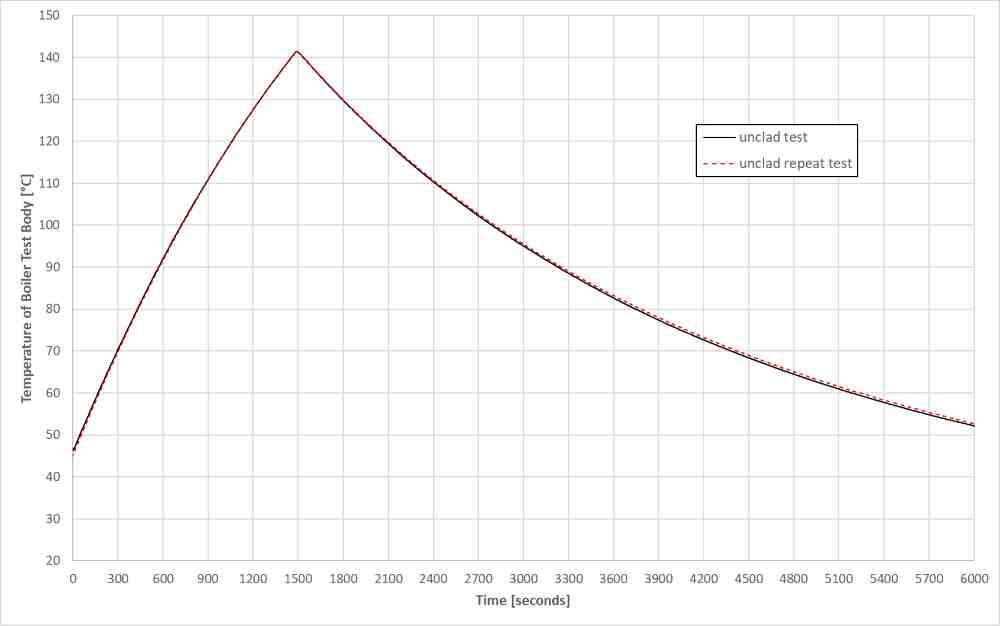

Initially I have done some repeatability testing on the cooling curves. So far these look good.

As you can see, each test takes around 2 hours and so in the meantime I have started making a simple mathematical model of this test object. Let me know any ideas for thermal insulation?

The thermal conductivity of wood versus density is an interesting plot and hence shows why I have used balsa wood as the pads.

Initially I have done some repeatability testing on the cooling curves. So far these look good.

As you can see, each test takes around 2 hours and so in the meantime I have started making a simple mathematical model of this test object. Let me know any ideas for thermal insulation?

For the insulation I think it's a balance between theoretical and practical application in such a miniature environment, and also conduction vs radiation.

- A trapped layer of gas would in theory be effective but you would need a decent gap 10mm+ to prevent radiant heat becoming dominant.

- Glass fibre etc has great performance in theory but once you compress it the performance drops, so how you would maintain effective performance at low thickness would be difficult.

- PIR or foam type insulation is super effective but getting a good uniform layer would be tough, perhaps spray foam a layer then turn off the excess to get a consistent 3-4mm thickness, then wrap in something for structural protection. Zero experience if this is possible.

- Neoprene could be a good balance of performance and practicality to apply and structural strength.

Brainstorm, perhaps helpful perhaps not.

Fitz.

- A trapped layer of gas would in theory be effective but you would need a decent gap 10mm+ to prevent radiant heat becoming dominant.

- Glass fibre etc has great performance in theory but once you compress it the performance drops, so how you would maintain effective performance at low thickness would be difficult.

- PIR or foam type insulation is super effective but getting a good uniform layer would be tough, perhaps spray foam a layer then turn off the excess to get a consistent 3-4mm thickness, then wrap in something for structural protection. Zero experience if this is possible.

- Neoprene could be a good balance of performance and practicality to apply and structural strength.

Brainstorm, perhaps helpful perhaps not.

Fitz.

Nigel Taylor

Established Member

For the insulation I think it's a balance between theoretical and practical application in such a miniature environment, and also conduction vs radiation.

- A trapped layer of gas would in theory be effective but you would need a decent gap 10mm+ to prevent radiant heat becoming dominant.

- Glass fibre etc has great performance in theory but once you compress it the performance drops, so how you would maintain effective performance at low thickness would be difficult.

- PIR or foam type insulation is super effective but getting a good uniform layer would be tough, perhaps spray foam a layer then turn off the excess to get a consistent 3-4mm thickness, then wrap in something for structural protection. Zero experience if this is possible.

- Neoprene could be a good balance of performance and practicality to apply and structural strength.

Brainstorm, perhaps helpful perhaps not.

Fitz.

Hi Fitz, yes, it is a balance. although the small gap I used on the vertical boiler worked quite well. The Teflon cooking sheets are a good first wrap, although even this eats into my 1.5mm total thickness available.

Some use silicon sheet, but that appears to be a better thermal conductor than teflon. I will have a look at neoprene.

Best regards, Nigel

Nigel Taylor

Established Member

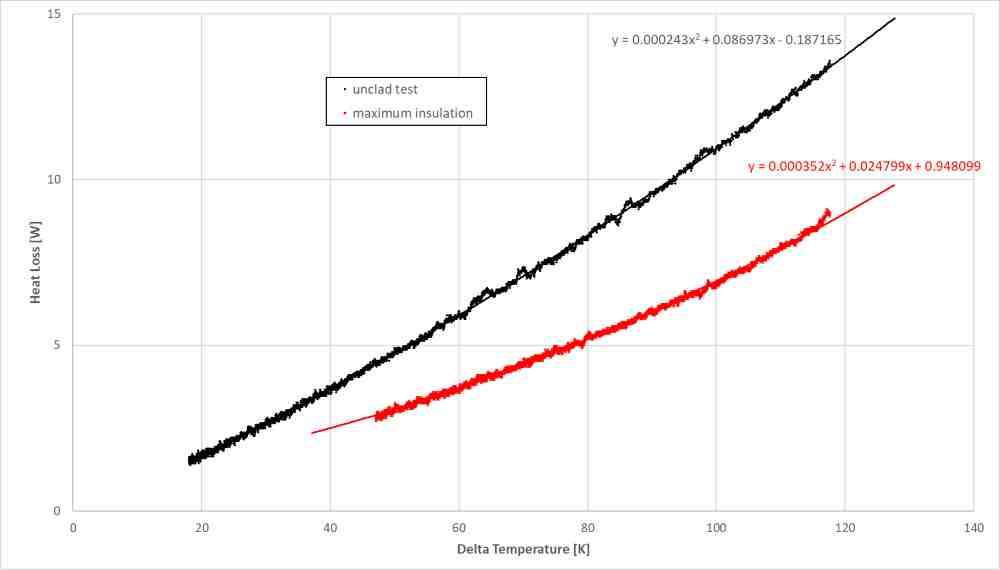

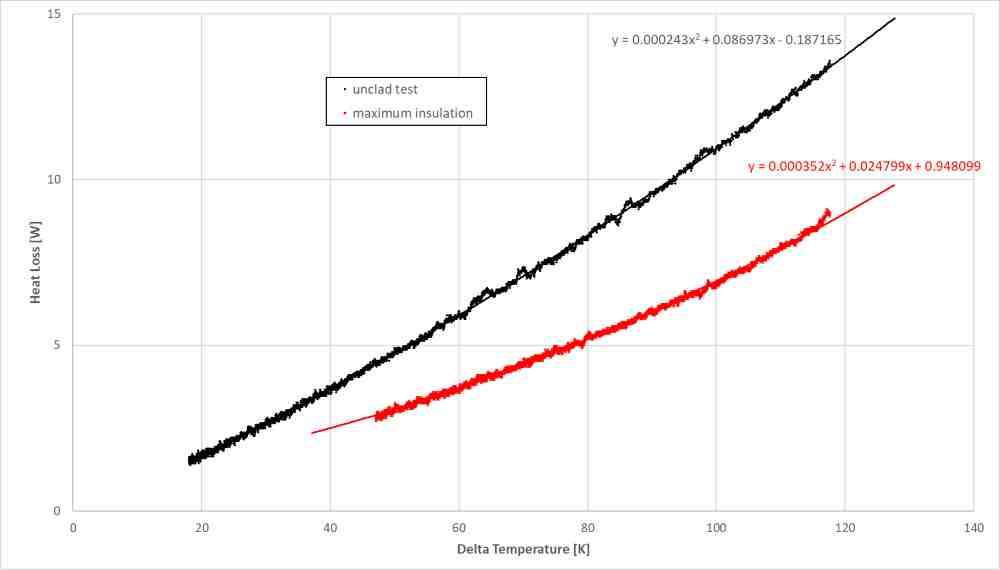

The unclad versus maximum (is it maximum?) insulation has now been tested and the data shows a significant difference. I think enough to bookend the problem. Quite frankly my test object would be better if it was about 300mm long to make the losses at the ends less significant. However, for now I can test a range of insulation between these bounds.

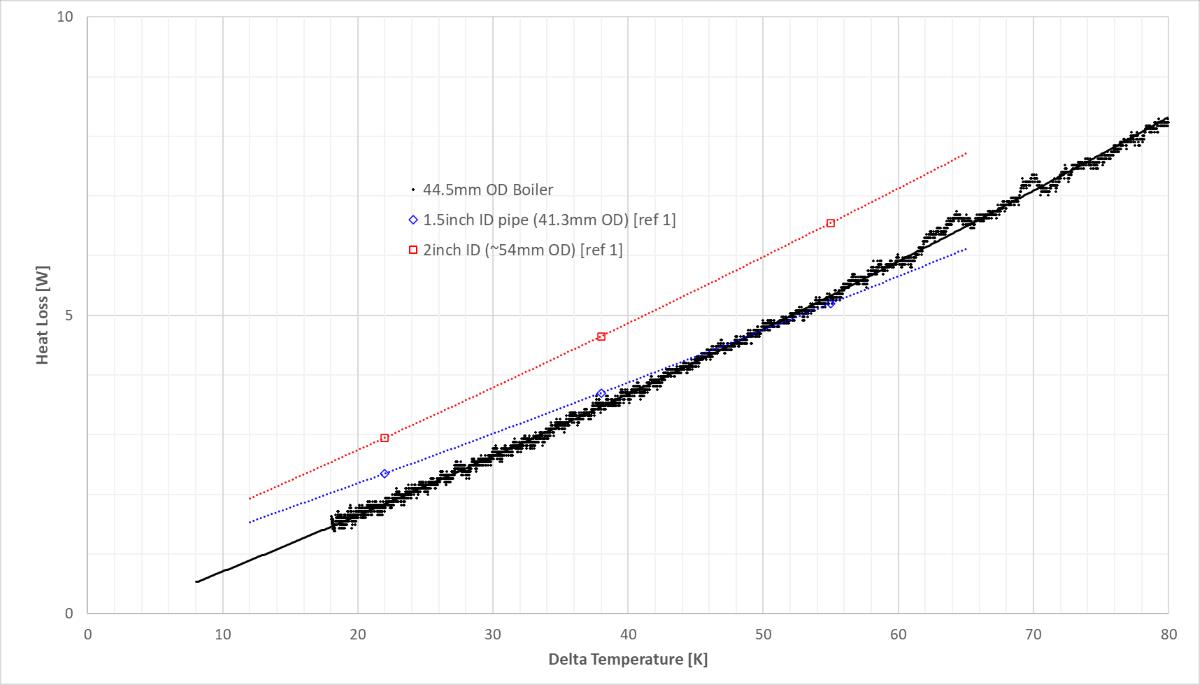

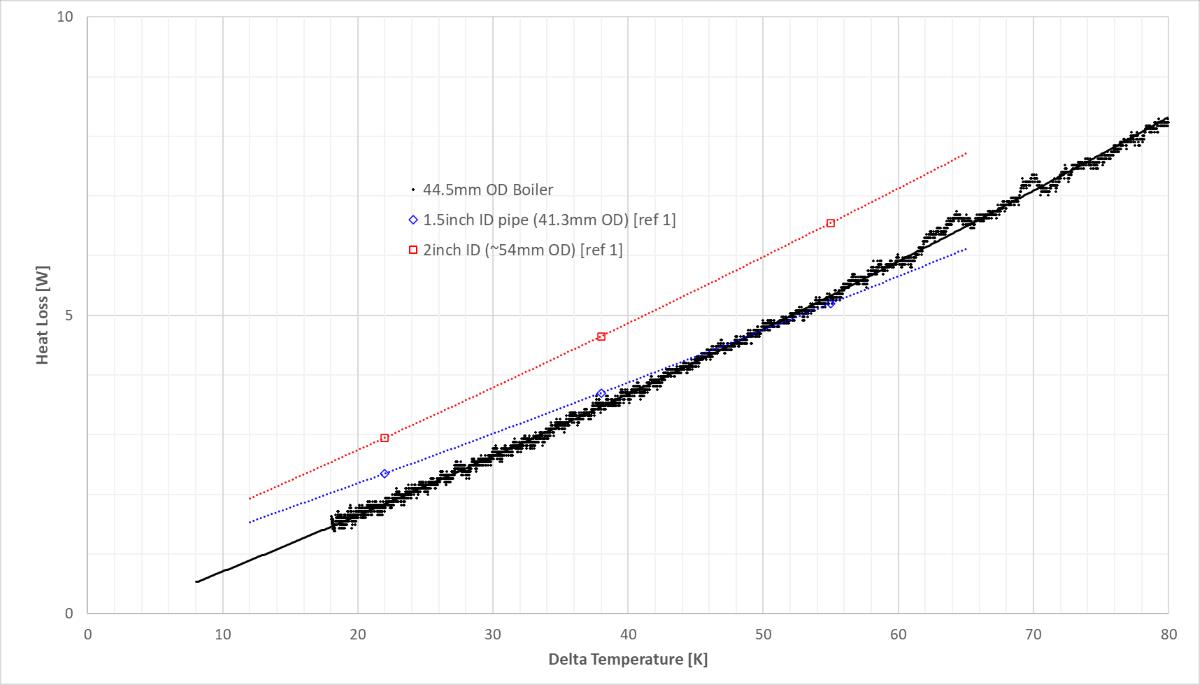

Also, Boiler heat loss versus published data for copper pipes used in a central heating system shows that there is a close relationship to the heat loss from the unclad boiler.

I've now tested some thinner wraps and multi-layers, just need to do some calculations and I will post this.

Also, Boiler heat loss versus published data for copper pipes used in a central heating system shows that there is a close relationship to the heat loss from the unclad boiler.

I've now tested some thinner wraps and multi-layers, just need to do some calculations and I will post this.

Adam W.

A Major Clanger

I'm loving your attention to detail, it's inspiring to say the least.

Nigel - there are specific insulation materials for model boilers - it normally takes the form of ceramic matting, which is quite flexible and easily cut to size - Page 10 of this catalogue is just one example.

G.

G.

Nigel Taylor

Established Member

Hi Gordon, thanks, hadn't seen that. I have just tested some ceramic matting that I had already, but will get some of this too to test. Best regards, NigelNigel - there are specific insulation materials for model boilers - it normally takes the form of ceramic matting, which is quite flexible and easily cut to size - Page 10 of this catalogue is just one example.

G.

Nigel Taylor

Established Member

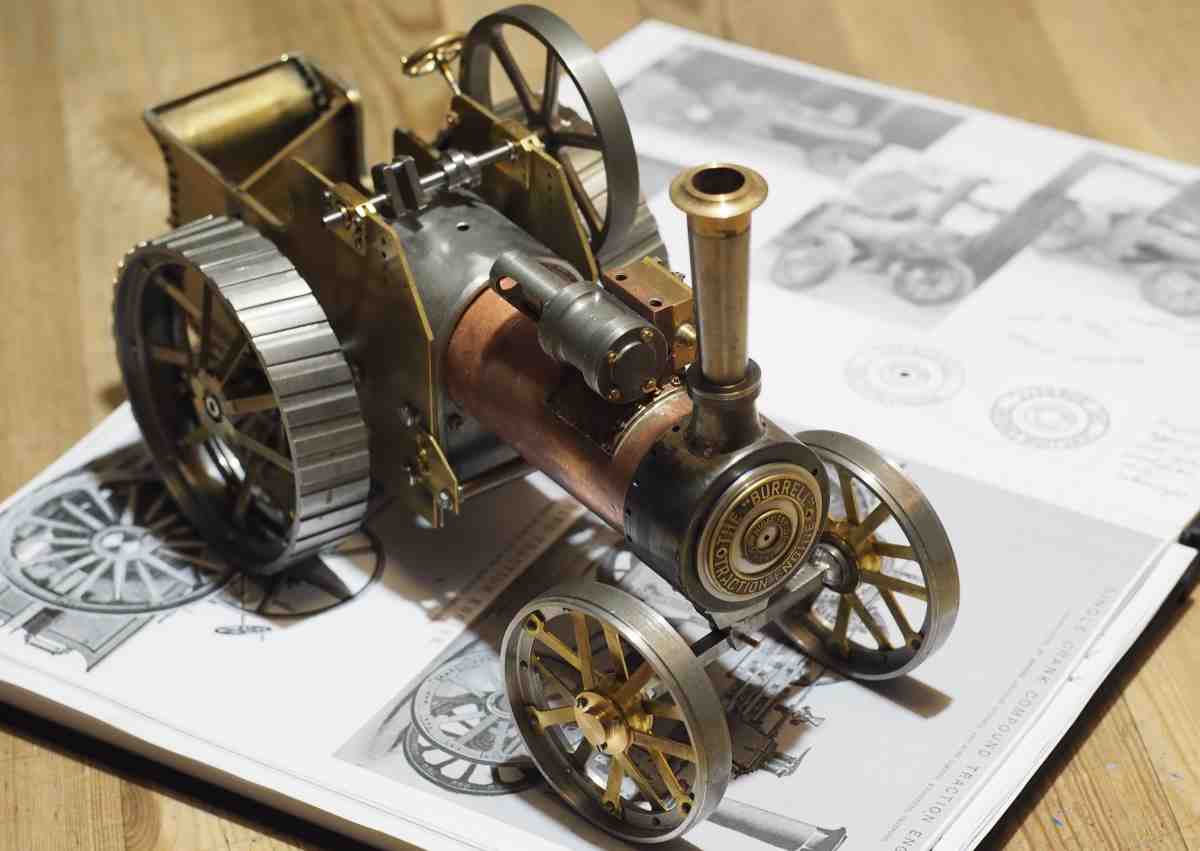

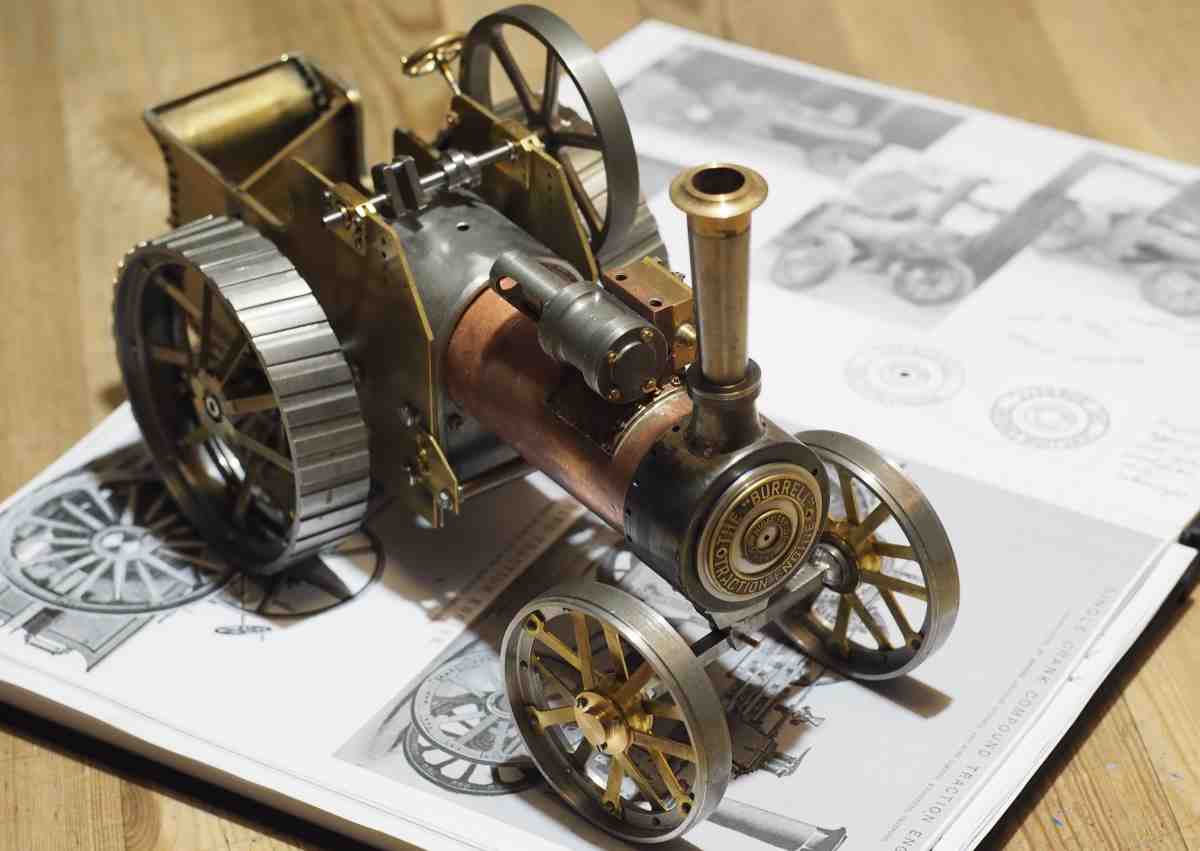

The flat smokebox door was annoying me, so I made a radius turning tool and then machined a domed door with a radius of 71.4mm

I think this curved smokebox door looks better

I think this curved smokebox door looks better

Jamesc

Established Member

The smoke box door definately looks better, it would have driven you mad if you hadn't changed it.

James

James

Hodge911

Member

WOW AMAZING!!!!!!

you sir are very talented!

you sir are very talented!

voyager

Established Member

just wow !

Molynoox

Established Member

Just stumbled across this thread, quite ridiculous what somebody can achieve with enough skill, patience and determination.

Not just the model making but all the theoretical analysis on the boiler design too, just stunning.

I would be interested to know what your actual job is assuming it is something to do with the model making? I'm curious because if I was to create something like this project I would want to be paid about £20k for it and I'm pretty sure nobody is going to pay that, even though it's probably worth that much in ingenuity and hours. Or maybe somebody does pay that, I have no idea. Just curious how this stuff works commercially. You deserve every bit of good fortune you get though! Amazing.

Martin

Not just the model making but all the theoretical analysis on the boiler design too, just stunning.

I would be interested to know what your actual job is assuming it is something to do with the model making? I'm curious because if I was to create something like this project I would want to be paid about £20k for it and I'm pretty sure nobody is going to pay that, even though it's probably worth that much in ingenuity and hours. Or maybe somebody does pay that, I have no idea. Just curious how this stuff works commercially. You deserve every bit of good fortune you get though! Amazing.

Martin

Similar threads

- Replies

- 12

- Views

- 3K

- Replies

- 12

- Views

- 2K

- Replies

- 42

- Views

- 12K