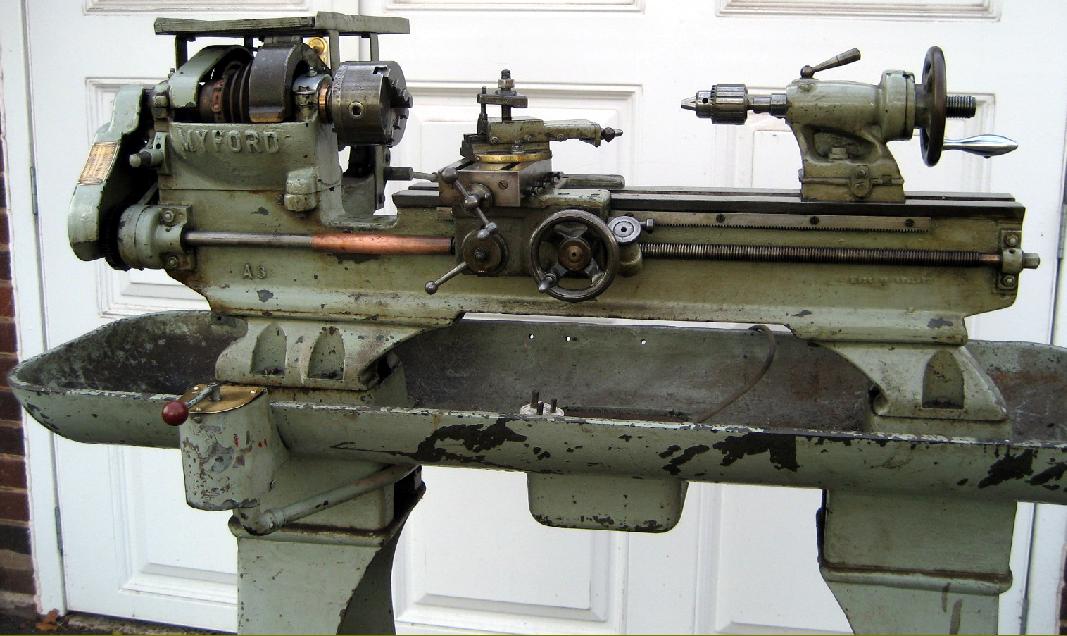

Following a recent spell of curiosity and a moment of insanity I have bought myself a Myford ML4. I'm quite certain that the stand it came with is not meant for the diminutive ML4 and I'm thinking about changing it for something smaller. Amongst the boxes of rust that came with it are some extra lathe parts that I am sure come from another lathe. I'd like to identify them but lathes.co.uk hasn't helped so far.

Obviously some photos are needed and I'll sort those out in the next few days. Is it worth me posting them up here or is there a better forum for this sort of thing?

Obviously some photos are needed and I'll sort those out in the next few days. Is it worth me posting them up here or is there a better forum for this sort of thing?