You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathe stand

- Thread starter TA09

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Orraloon

Established Member

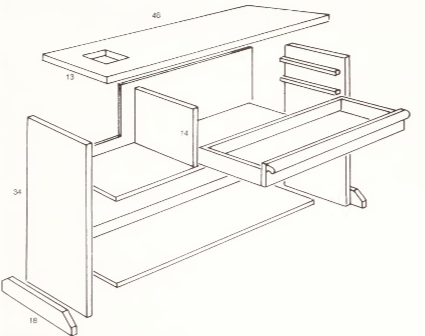

I built mine based on a plan in Keith Rowley's book ''Woodturning: A Foundation Course''. The legs are 100x100mm the top is 2 layers of 19m chipboard flooring. Frame bolted together. As long as its heavy and solid to absorb the vibrations. Some put bricks or sand bags in the bottom but I have not needed to do that.

Regards

John

Regards

John

Attachments

I agree with Orraloon. I think the ply frame as sketched would be too flimsy. If you go that way, I suggest doubling up on the thicknesses (to 36 mm, two sheets glued together or one thick sheet) of the sides and the back, and also make the back full height without that big cutout. If you need the cutout for a motor than frame it with something thick.

It's really better to frame it using 100 x 100 legs and at least 35 mm top. You don't need to do fancy joinery, since if you fill the sides in with 18 mm ply that will make the whole thing stiff enough.

Weight low down and stiffness are important. If you can attach it to a wall that is also very good.

It's really better to frame it using 100 x 100 legs and at least 35 mm top. You don't need to do fancy joinery, since if you fill the sides in with 18 mm ply that will make the whole thing stiff enough.

Weight low down and stiffness are important. If you can attach it to a wall that is also very good.

As long as its heavy and solid to absorb the vibrations. Some put bricks or sand bags in the bottom ...

In the base of mine there are the bricks from nine night storage heaters.

In the base of mine there are the bricks from nine night storage heaters.

Richard_C

Established Member

You need to be able to lean in over the bed to do things like hollowing bowls, so ideally the front edge of the bed needs to be close to the front of the bench. I made mine from some 2x4 decking support joists, like a giant saw trestle but with one shelf about 30cm down. 10mm bolts, crude, simple, quick and cheap. Top was 2 pieces wide so c. 8", legs splayed out like a trestle just beyond the ends of the bed so not in the way. First lathe, decided I would make something 'better' once I had more experience of what I needed. No need has yet arisen

Steve Maskery

Established Member

I have a Record Power lathe stand for sale. Built like a tank and will take anything.

PM me if you are interested.

PM me if you are interested.

graduate_owner

Established Member

You could buy one of the original ml8 stands. They are sturdy welded steel. Some people put weights in them for even more stability.

K

K

Yeah I would, but have not seen them here in Norway. The original stand would be best.graduate_owner":2jow1qj6 said:You could buy one of the original ml8 stands. They are sturdy welded steel. Some people put weights in them for even more stability.

K

Sent fra min LYA-L29 via Tapatalk

Steve Maskery

Established Member

Ah... I didn't realise you were in Norway...