Derek Cohen (Perth Oz)

Established Member

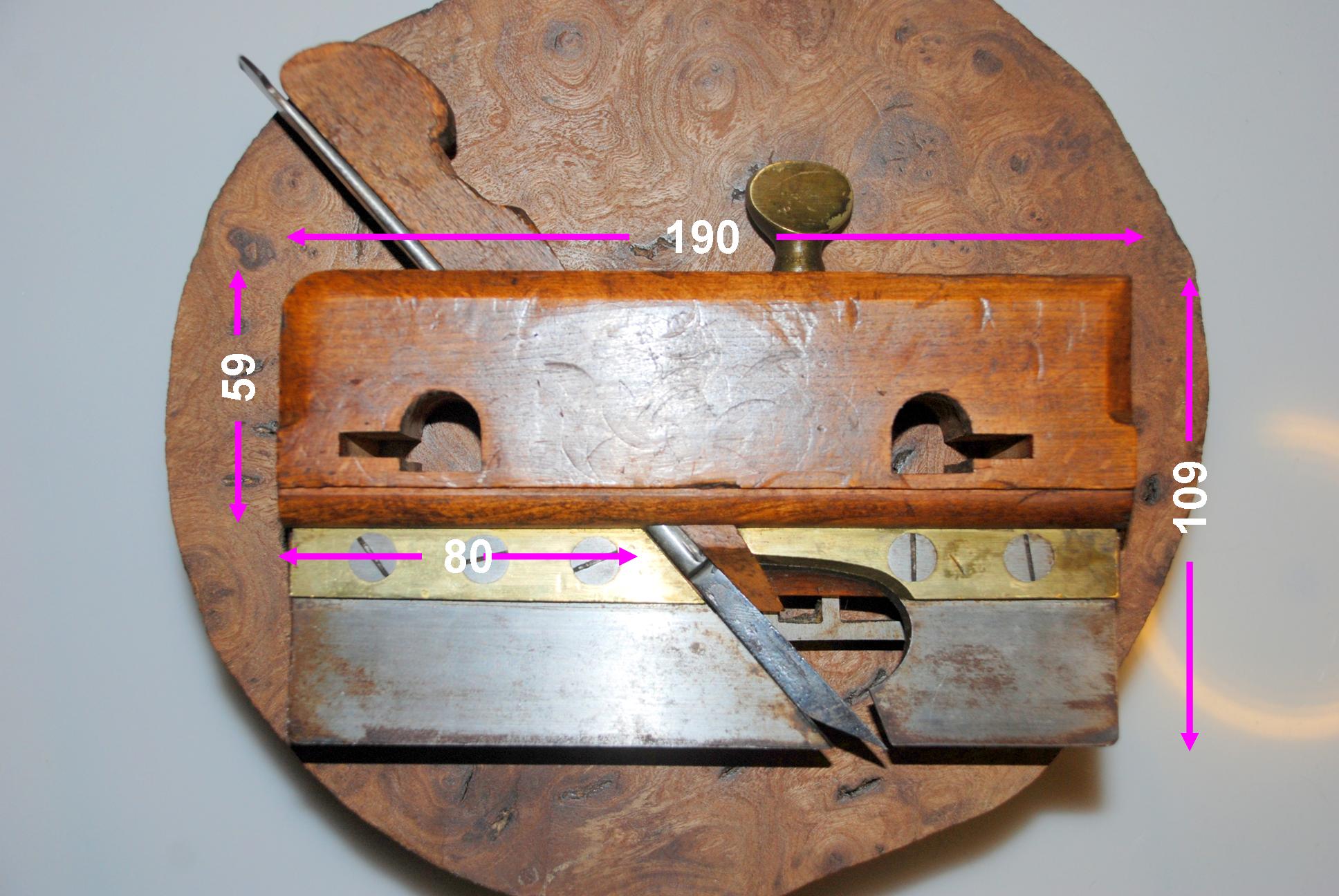

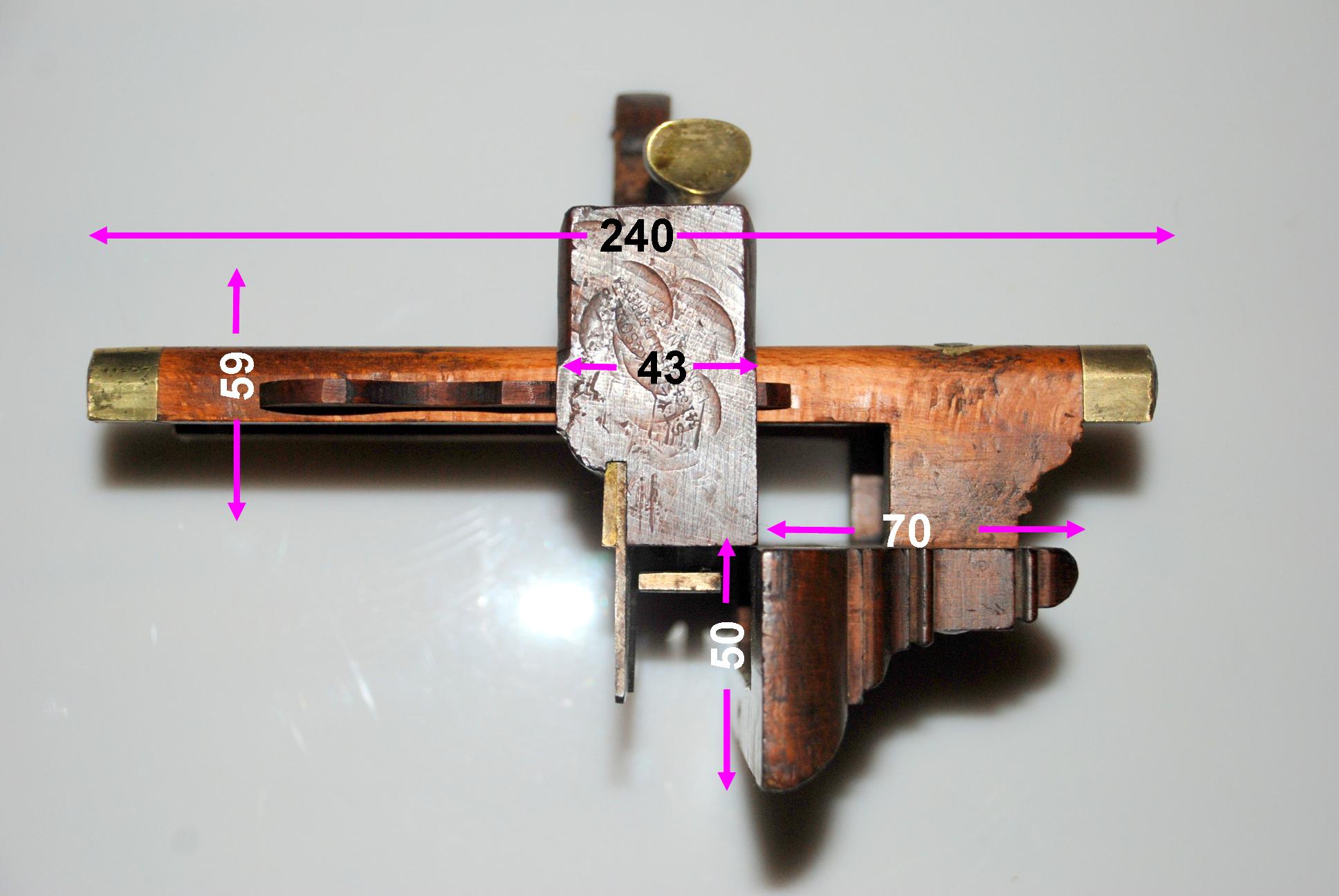

This is a long shot but I must ask whether anyone here can identify these plough plane blades from the UK?

They are a set of 8 (numbered 1 through 8 ) that I purchased for a plough plane I am about to build, and run from 3/16" through to 5/8". The blades are tapered and laminated. There are no maker's marks and the only markings are the number and "Warranted Cast Steel". The grooves are nicely done (clean and straight), so these are not likely to be shopmade. They have the look of cared-for vintage steel that were made by a known blademaker.

Regards from Perth

Derek

They are a set of 8 (numbered 1 through 8 ) that I purchased for a plough plane I am about to build, and run from 3/16" through to 5/8". The blades are tapered and laminated. There are no maker's marks and the only markings are the number and "Warranted Cast Steel". The grooves are nicely done (clean and straight), so these are not likely to be shopmade. They have the look of cared-for vintage steel that were made by a known blademaker.

Regards from Perth

Derek