On holiday in Sweden I saw traditional wooden hot tubs heated by submersible wood fired stoves. These tubs are available in the UK but cost around £2000.

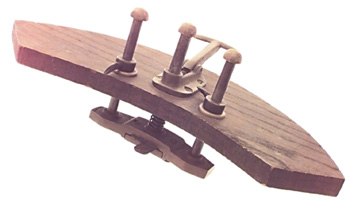

The problem with diy construction is that it requires precise cooperage skills to ensure watertightness. I've experimented with scaffolding board and an old pond liner and have made an oblong tub that is watertight. I plan to have a tub liner made to measure (about £200) and install a woodfired heater (about £400). The thing is I would much preffer a circular tub. The way I think that a circular tub could be made would be using three foot high sections of saffold board (I've got dozens of these boards). I'm planning to create a D shaped groove along the length of one side of these boards and plane the opposite side into a shallow C shape. The boards will fit together with the C side of one board fitting into the D side of its partner. I'm thinking that this will obviate the need for precise joint measurements. The base will be a circle of marine ply. Waterproofing will be provided by a vinyl liner.

My problem is that I have very basic carpentry skills. Would it be easy to make a curved edge on one side of an inch and a half board and a C shaped groove on the other using a router? I've never used a router. Any advice would be appreciated.

Cheers!

The problem with diy construction is that it requires precise cooperage skills to ensure watertightness. I've experimented with scaffolding board and an old pond liner and have made an oblong tub that is watertight. I plan to have a tub liner made to measure (about £200) and install a woodfired heater (about £400). The thing is I would much preffer a circular tub. The way I think that a circular tub could be made would be using three foot high sections of saffold board (I've got dozens of these boards). I'm planning to create a D shaped groove along the length of one side of these boards and plane the opposite side into a shallow C shape. The boards will fit together with the C side of one board fitting into the D side of its partner. I'm thinking that this will obviate the need for precise joint measurements. The base will be a circle of marine ply. Waterproofing will be provided by a vinyl liner.

My problem is that I have very basic carpentry skills. Would it be easy to make a curved edge on one side of an inch and a half board and a C shaped groove on the other using a router? I've never used a router. Any advice would be appreciated.

Cheers!