Out int shed

Established Member

Hello Chaps,

Found this site just over a month ago. I have enjoyed reading the informative and funny posts - I think its now time for me to contribute.

Here's my first post, and I think it only right that it should be a WIP of my new workshed.

So far, I have spent 1 weekend pulling down the old shed and outbuildings:

Yes, that is a fox on the roof.

After the old shed, there was an outside poo loo to come down. This pick shows the brick out house after it met my sledge hammer for a day. You can just see the remains of the door lining of the out house on the right.

note to self; must remember to turn of the water supply to the toilet before pulling the walls down!

After another day of bashing, the hardcore is ready for sand then concrete.

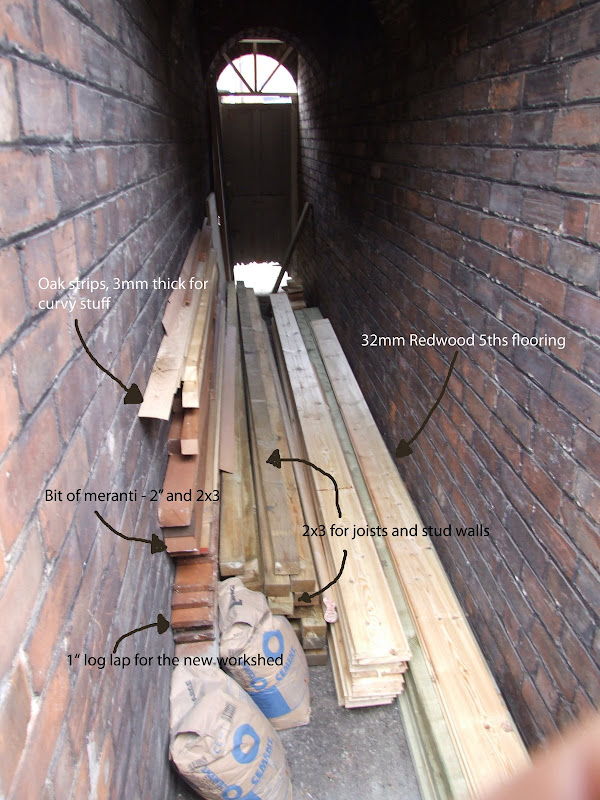

Once a new slab is laid I can crack on with the floor joists. 3x2 should do, 400 centres spanning 2.3 meters. I have some 32mm T&G to go on top of the joists.

Total shed floor will be 2.3X4.2m or there abouts. Im thinking of putting breeze blocks down onto the concrete slab and laying the joists onto those. Is it a good idea to lay the blocks into the wet concrete to set them in?

p.s - how do i make the pictures bigger - they have a native resolution of 1280X1024 so cant understand why they are so small, unless google picture hosting shrinks the picture size??

Found this site just over a month ago. I have enjoyed reading the informative and funny posts - I think its now time for me to contribute.

Here's my first post, and I think it only right that it should be a WIP of my new workshed.

So far, I have spent 1 weekend pulling down the old shed and outbuildings:

Yes, that is a fox on the roof.

After the old shed, there was an outside poo loo to come down. This pick shows the brick out house after it met my sledge hammer for a day. You can just see the remains of the door lining of the out house on the right.

note to self; must remember to turn of the water supply to the toilet before pulling the walls down!

After another day of bashing, the hardcore is ready for sand then concrete.

Once a new slab is laid I can crack on with the floor joists. 3x2 should do, 400 centres spanning 2.3 meters. I have some 32mm T&G to go on top of the joists.

Total shed floor will be 2.3X4.2m or there abouts. Im thinking of putting breeze blocks down onto the concrete slab and laying the joists onto those. Is it a good idea to lay the blocks into the wet concrete to set them in?

p.s - how do i make the pictures bigger - they have a native resolution of 1280X1024 so cant understand why they are so small, unless google picture hosting shrinks the picture size??