bugbear

Established Member

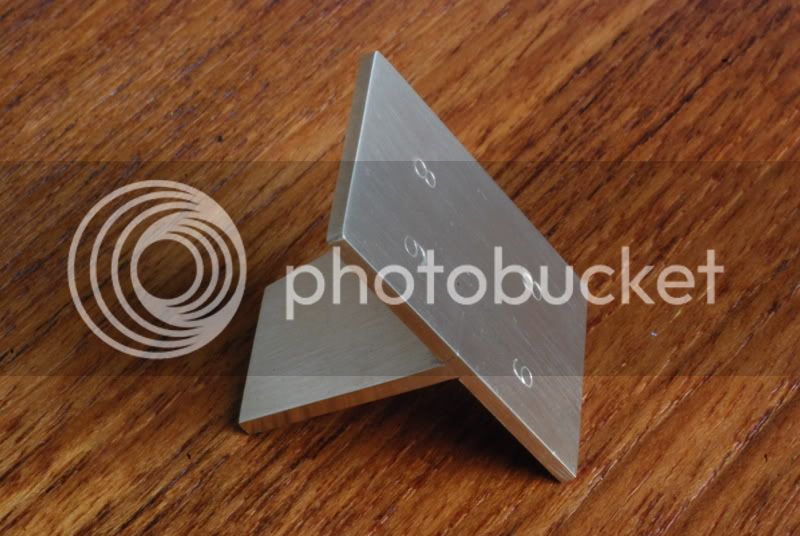

Whilst reading George Ellis' book, I noticed he prints (p66) a dovetail marking gauge design. It

couldn't be simpler to make - it's just a sawn of tenoned rail, with the shoulders

cut to the angle desired.

The opposite faces give the two angles required, and the two sides of the tenon

mean you can always seat the reference face (the shoulder) nicely on the workpiece.

Hacing read the book, I realised that I've seen quite a few of these in old toolboxes,

in the "odd and ends" drawer (along with a few screws, bits of chalk etc...)

so I don't believe this to be just book learnin'.

BugBear

couldn't be simpler to make - it's just a sawn of tenoned rail, with the shoulders

cut to the angle desired.

The opposite faces give the two angles required, and the two sides of the tenon

mean you can always seat the reference face (the shoulder) nicely on the workpiece.

Hacing read the book, I realised that I've seen quite a few of these in old toolboxes,

in the "odd and ends" drawer (along with a few screws, bits of chalk etc...)

so I don't believe this to be just book learnin'.

BugBear