Scouse

Established Member

Richard T":c3436c0b said:...electric ...

e-lec-tric? Sorry, I didn't understand that bit; I just need to go and look it up, must be something to do magic and witchcraft or sumfink...! :mrgreen:

Richard T":c3436c0b said:...electric ...

Scouse":2rmu1oxv said:Richard T":2rmu1oxv said:...electric ...

e-lec-tric? Sorry, I didn't understand that bit; I just need to go and look it up, must be something to do magic and witchcraft or sumfink...! :mrgreen:

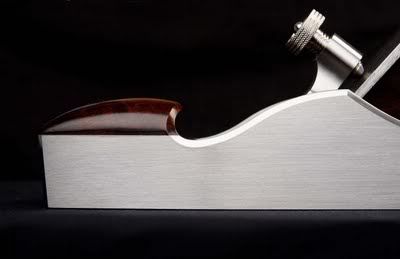

jimi43":12l74b8o said:I simply love Konrad's new "speedboat" design...very 30's!

Enter your email address to join: