I'm building a 5x5 meter shed because my workshop is full and we need more storage.

I started on the foundations for my new shed last July.

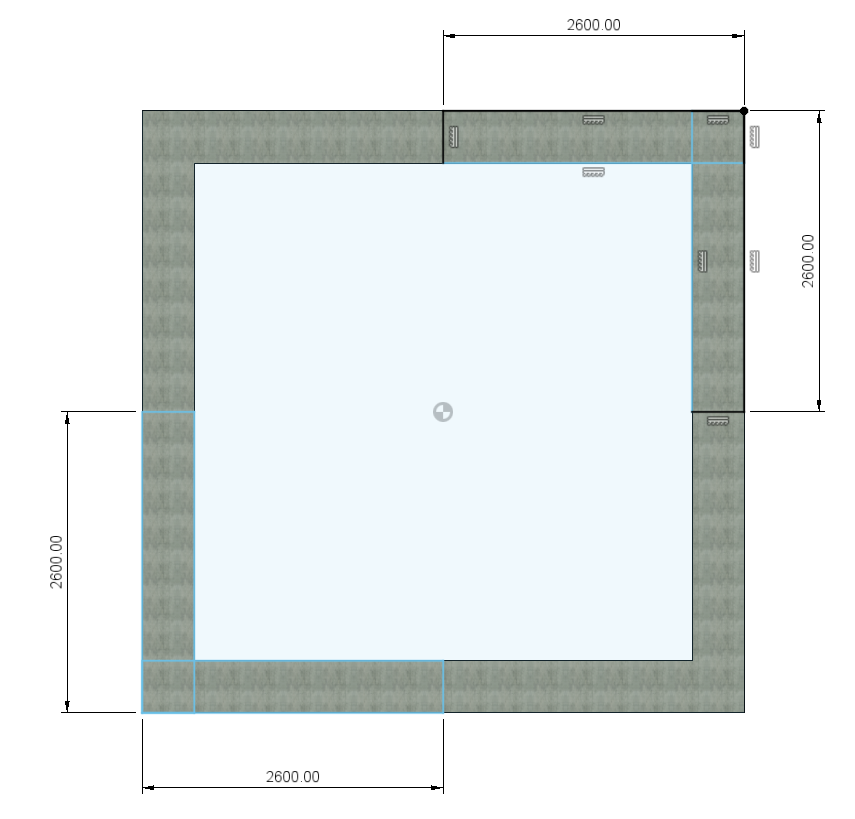

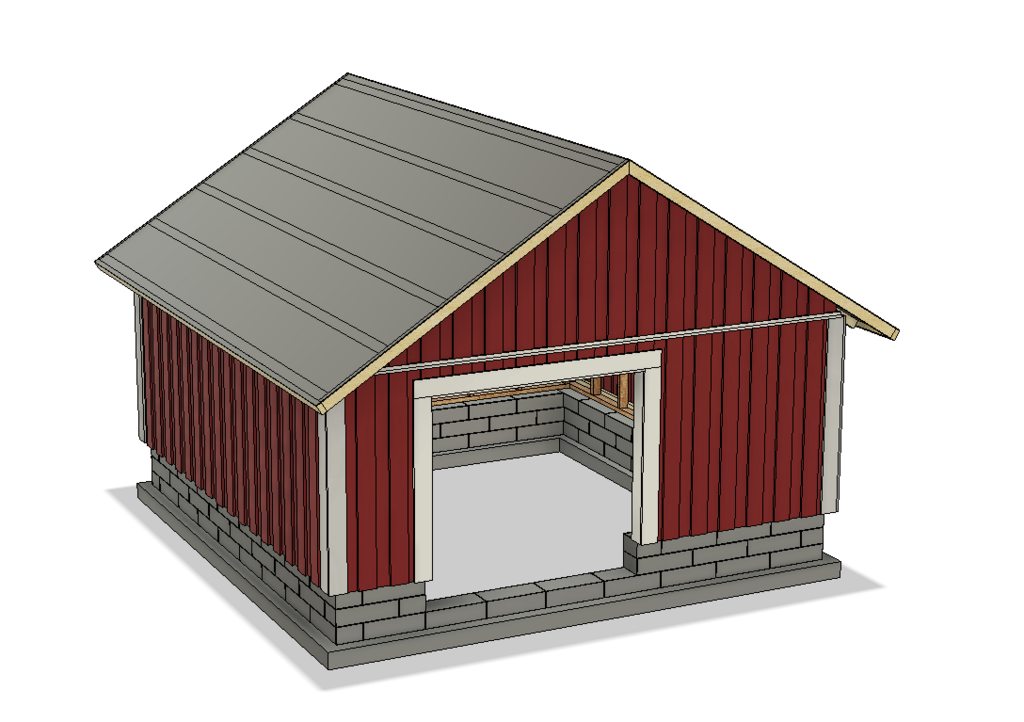

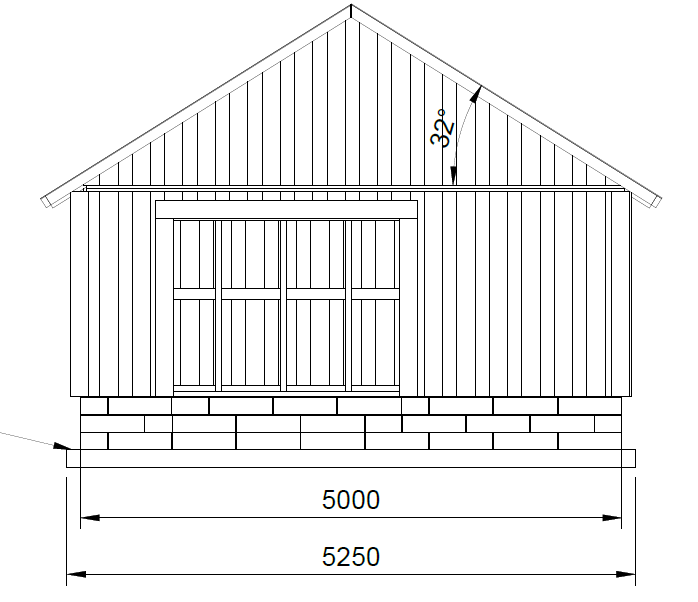

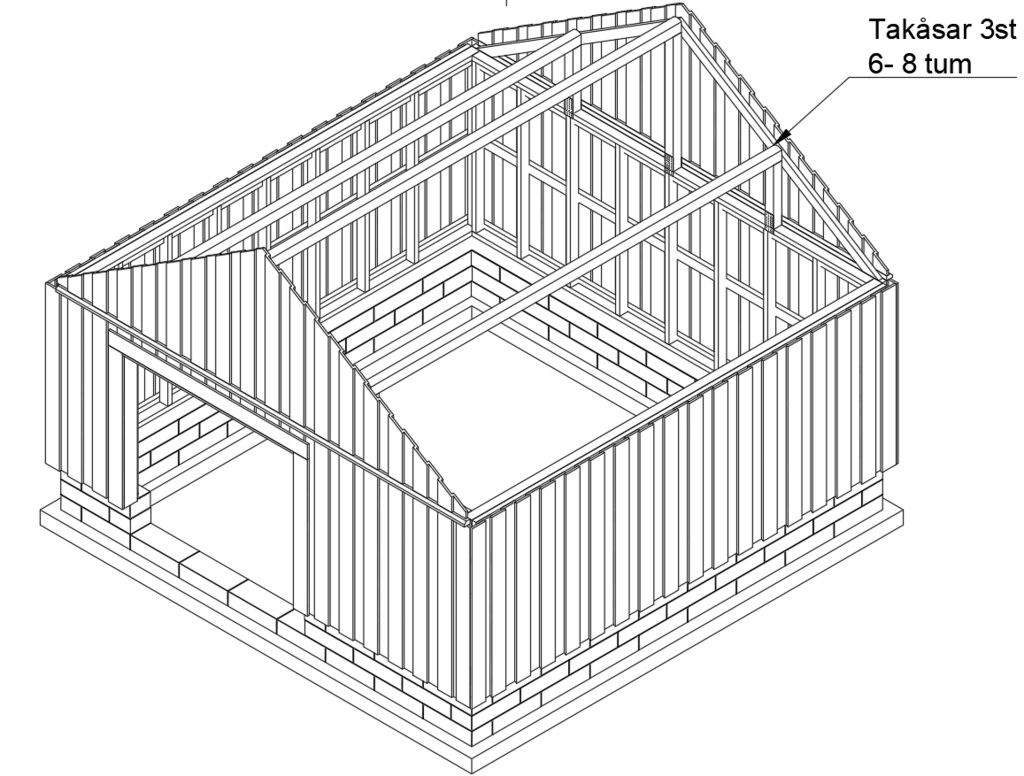

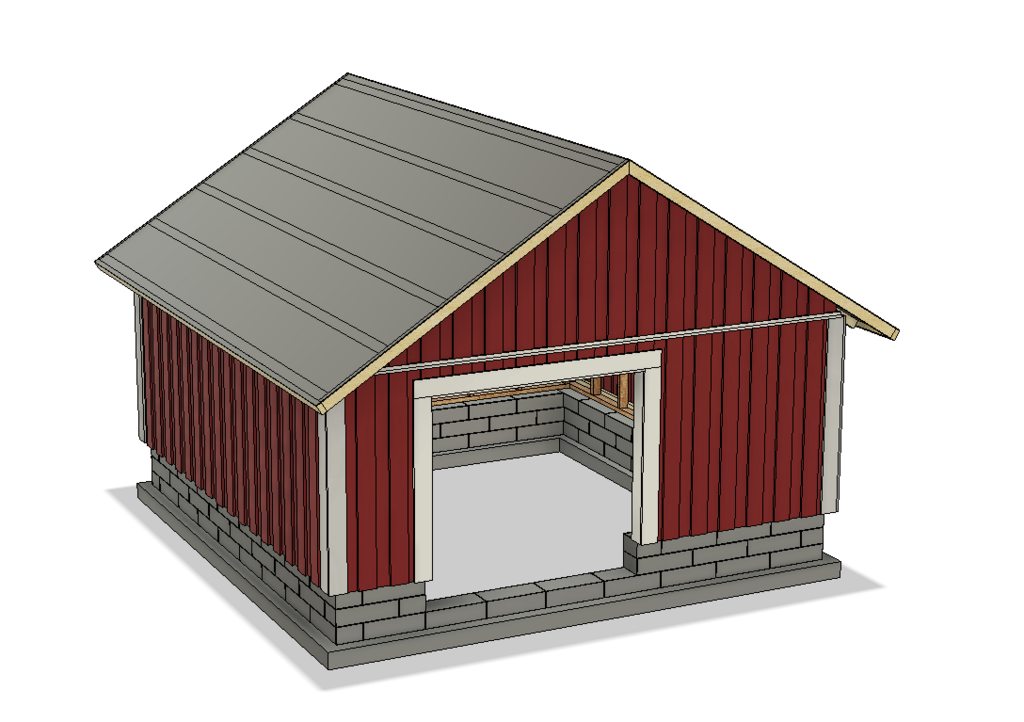

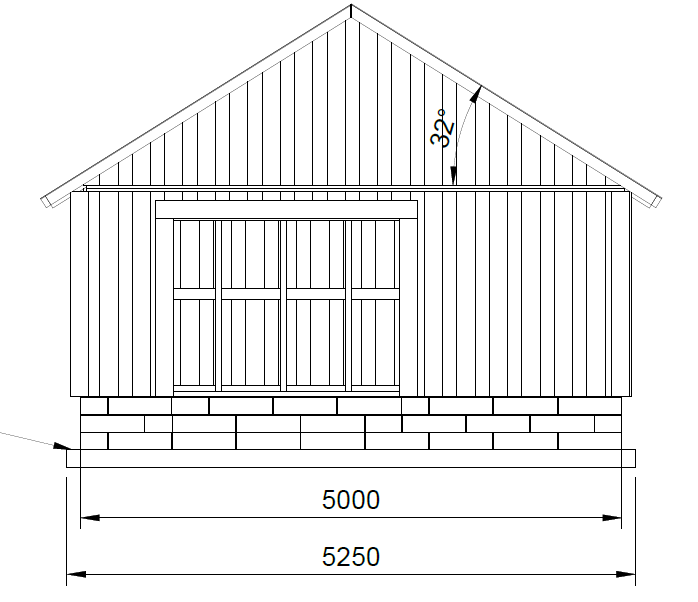

Cad preview of what it will look like:

The cat donesn't seem to be afraid of heavy machinery, as soon as there was a lull in activity they'd be right in there, curious about everything, weird cats.....

And this is it done, earth dug out and moved around, replaced with gravel that's been compacted and leveled. Still need to get insulation that will sit under the concrete "foot" and underground drainage pipes that will circle the foundation and lead away water towards a ditch off picture. The next step is building concrete forms:

One of the twins (David) had a swell time with all the big machines, got to run the compactor for a time as well.

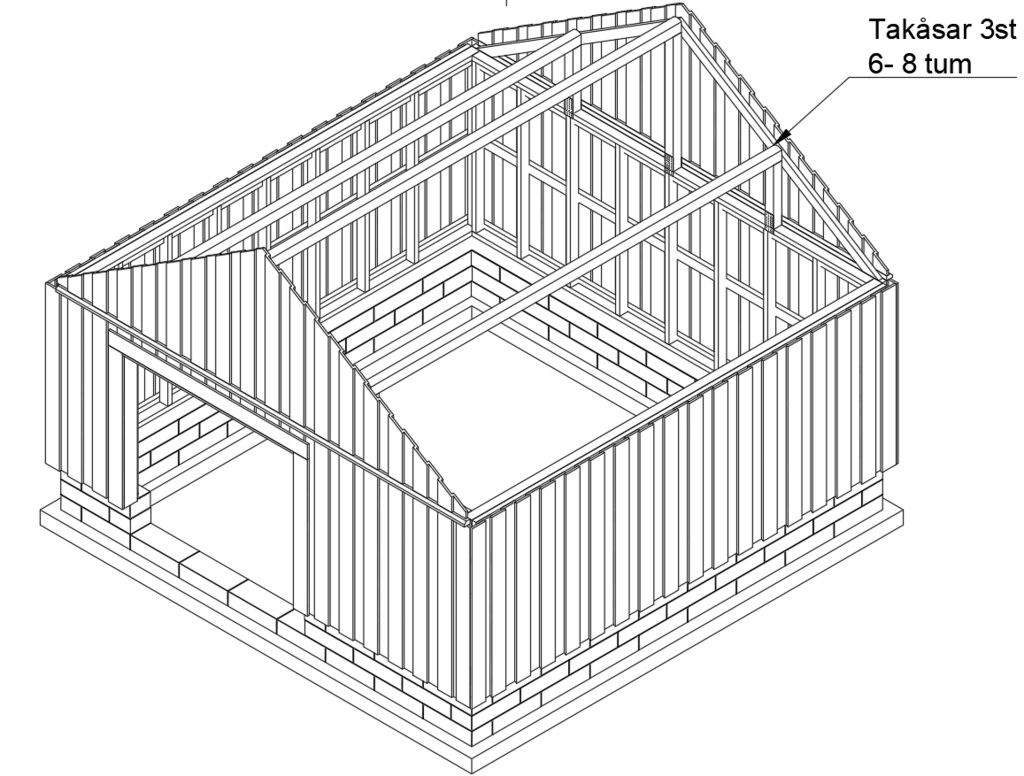

Some screenshots from the cad showing the general build. It's just going to be an uninsulated shed for storing things that don't need to be in the warmth. It will also serve as a place for more tools, I hope to store my anvil and a forge or two permanently by the door.

I started on the foundations for my new shed last July.

Cad preview of what it will look like:

The cat donesn't seem to be afraid of heavy machinery, as soon as there was a lull in activity they'd be right in there, curious about everything, weird cats.....

And this is it done, earth dug out and moved around, replaced with gravel that's been compacted and leveled. Still need to get insulation that will sit under the concrete "foot" and underground drainage pipes that will circle the foundation and lead away water towards a ditch off picture. The next step is building concrete forms:

One of the twins (David) had a swell time with all the big machines, got to run the compactor for a time as well.

Some screenshots from the cad showing the general build. It's just going to be an uninsulated shed for storing things that don't need to be in the warmth. It will also serve as a place for more tools, I hope to store my anvil and a forge or two permanently by the door.

Last edited: