Right, where were we? Ah yes.....

Having assembled the frame, I made a quick softwood frame for the drawer runners:

Time to take a few deep breaths and cut the table top to size. I never used to get nervous going out to bat in a crisis in front of 20,000 people and a TV audience, but I sure as hell get nervous with stuff like this. I thought about how I was going to do this days in advance. First job was to make a really accurate template:

After placing the template in position on the table top, I used the appropriate sized forstner bit to locate the hole for the corner of the leg cut-outs. Remember, the legs have an aggressive round over:

I secured a guide in place (I can tell you this took ages, checking, re-checking, taking it apart and starting again....):

After completing the little straight cuts with a tenon saw (no photo), I did a trial fit. It dropped in first time......which isn't necessarily a good thing. However, three of the cut outs were absolutely perfect, and one was a gnat's slack. Much better than I hoped!! Phew:

This is the not-quite-perfect one:

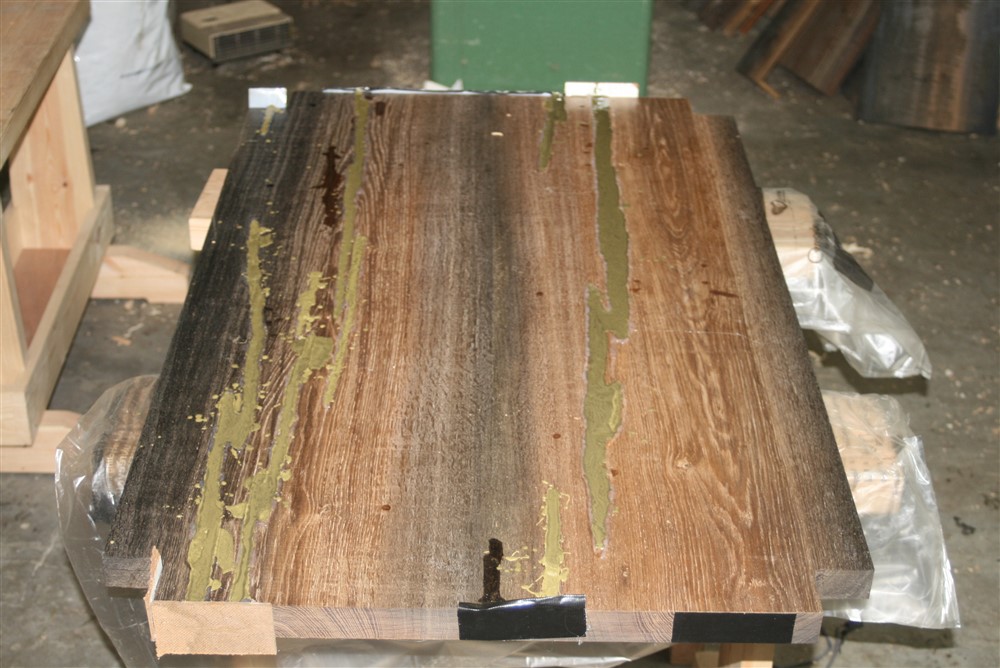

As if that wasn't enough to give me palpitations, next came the step which I'd been dreading from the moment I selected the timber: filling the top. First, I built little dam walls around all of the cracks with hot-melt glue:

I also taped up the ends of cracks where they showed on the end grain, or glued on some temporary dams of off-cuts of hardboard. Remember the cracks in the underside had already been filled with a cheap filler.

Then I mixed some of this:

...with some of this:

.........and trickled it into the cracks:

There's actually a little more to it than that. I did the bigger cracks in two pours, using just clear resin for the first bit, to within about 6 or 8 mm of the surface, then came back with the brass-filled resin the following day. Whilst that lot dried, I did secondary jobs such as making oak buttons:

.......and the little strap thingies for the drawer handles:

I hate wasting this precious timber, and I couldn't find any dark brown amongst my off cuts, so I had to generate some from the middle of a board.......hence the saw handles.

Marking out is such a pain on this dark wood, so once again.....masking tape.

Back to the table top. I sanded off the bulk of the resin:

Unfortunately, there were 3 or 4 low spots, including a couple on end-grain. Time for another pour:

Whilst that was drying I got on with finishing the rest of the table. My wife tells me that my workshop would have been uninhabitable by anyone with a sense of smell because of the resin, so there is the occasional bonus from not having one. Oil/ varnish/ white spirit mix on everything, then wipe it off within 7 minutes:

This Stanley no. 80 cabinet scraper was an absolute godsend:

I screwed some little blocks onto the ends of the table legs so that I could finish easily all the way done to the bottom:

Back to the top:

The brass is showing up matt and greenish in these photos. I've no idea why, because in real life it is satin and metallic.

Now, take a close look at this next photo. In sanding down the filler I finished off with 180 grit paper. This next picture shows the difference between sanding and finishing with a blade. The lower half (closer to the viewer) is sanded. The upper part (further away) is scraped. The sanded area looks dull and matt. The scraped wood looks glossy and bright:

I thinks that's rather persuasive, personally.

I hated doing this:

All my planes are razor sharp and well set, and normally end grain is a doddle. It wasn't with this stuff. In the end I had to just get it good enough and then stop, because I was in danger of going past my lines. It isn't the easiest wood to work with.

You've seen this before:

But not this:

I did a final assemble and minor adjustments, and brought it into the house. The body of the table and the drawers have had 4 coats of finish. I might just do one final coat on the drawer fronts and handles. The table top has only had one, so is just sitting in position for the sake of these photos:

The strap thingies over the drawer handles are just hot-melt glued in place temporarily, awaiting a committee decision.

Finally, there is a gap here which is crying out for a matching end table, so watch this space: