You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bending stainless steel rod

- Thread starter 58954b

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Will depend on the diameter of the rod.

Best to grip it in the vice sticking up together with a suitable piece of thicker steel bar of the dia of the "U" held horizontally and then bend it round that.

Jason

Best to grip it in the vice sticking up together with a suitable piece of thicker steel bar of the dia of the "U" held horizontally and then bend it round that.

Jason

MikeG.

Established Member

It will depend on the grade of the steel as to whether this will work with stainless steel. Some will be so tough that you just won't bend it, and some can be brittle and even snap. This would be an easy job with mild steel.

If it is already threaded, your next biggest problem is not wrecking the threads during the bending process.

If this is a length of ss threaded rod from a builders merchants or similar, then it will be cheap enough to have a gamble with. I would clamp between two pieces of scrap wood in the jaws of a well secured engineer's vice on a strong bench, and place a putlock (c 4 foot long piece of scaffold tube) over the exposed end (with the thread well wrapped in cloth).

Then grunt a lot, and sweat a bit, and push a bit, and you may persuade it to go somewhere near where you want it. If you resort to hitting it with a lump hammer, firstly, you will have to protect the thread somehow, and secondly, you will have to dampen the springing effect. The hammer and steel will just bounce around a lot. You need to hit it very near the bend, and not out on the free end of rod.

Best of luck.........what are you making?

Mike

If it is already threaded, your next biggest problem is not wrecking the threads during the bending process.

If this is a length of ss threaded rod from a builders merchants or similar, then it will be cheap enough to have a gamble with. I would clamp between two pieces of scrap wood in the jaws of a well secured engineer's vice on a strong bench, and place a putlock (c 4 foot long piece of scaffold tube) over the exposed end (with the thread well wrapped in cloth).

Then grunt a lot, and sweat a bit, and push a bit, and you may persuade it to go somewhere near where you want it. If you resort to hitting it with a lump hammer, firstly, you will have to protect the thread somehow, and secondly, you will have to dampen the springing effect. The hammer and steel will just bounce around a lot. You need to hit it very near the bend, and not out on the free end of rod.

Best of luck.........what are you making?

Mike

Oryxdesign

Established Member

Unless you already have the material you could just buy a couple from these guys

http://www.bendfast.co.uk/pages/products.html

http://www.bendfast.co.uk/pages/products.html

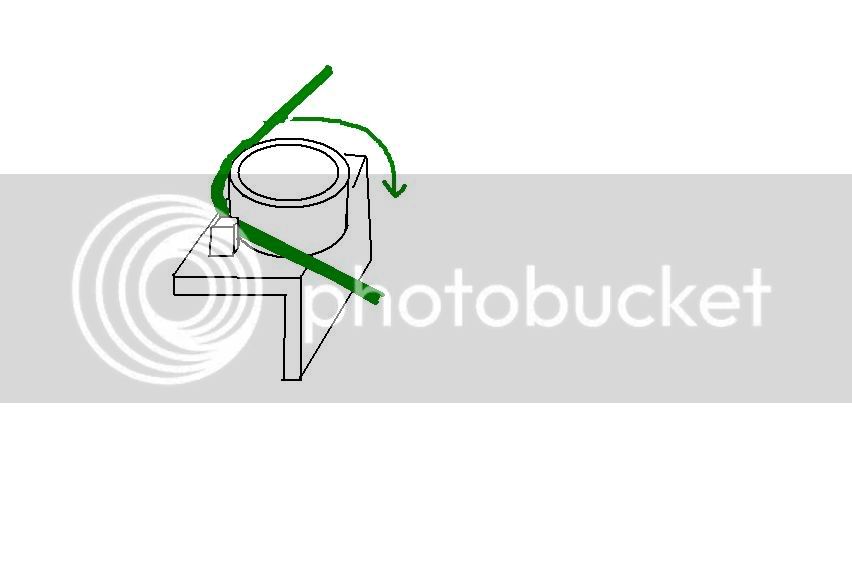

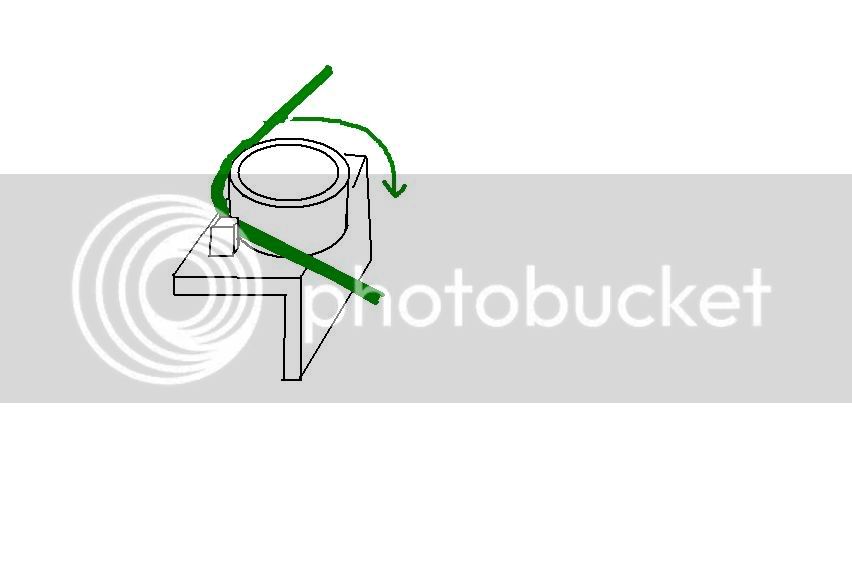

Fit a suitable former to something solid, and a stop, bend the length round the former and cut back the sides to length afterwards.

Leave the end of the studding long so you have something to pull it roiund with.

The former will need to be smaller than the size you want to account for springback.

No hassle, it wont snap, and you should just about be able to do it by hand.

Like this.

Leave the end of the studding long so you have something to pull it roiund with.

The former will need to be smaller than the size you want to account for springback.

No hassle, it wont snap, and you should just about be able to do it by hand.

Like this.

andycktm

Established Member

........or you could buy a couple of stainless exhaust clamps from halfords

Woodmagnet

Established Member

- Joined

- 23 Jan 2006

- Messages

- 1,668

- Reaction score

- 0

andycktm":2ojmpkx6 said:........or you could buy a couple of stainless exhaust clamps from halfords

+1 :sign3: :lol:

chunkolini

Established Member

A simple way of doing this.

Stick a piece of heavy tube in a vice horizontally, put the bar in and slip another piece of tube say a 2 or 3 feet long over the other end of the bar and haul on it gently in a series of tweaks so you make a row of very small bends to give an even curve.

I do lots of this stuff, I even have special tools for bending bar and strip and use this method most on smaller pieces.

Chunko'.

Stick a piece of heavy tube in a vice horizontally, put the bar in and slip another piece of tube say a 2 or 3 feet long over the other end of the bar and haul on it gently in a series of tweaks so you make a row of very small bends to give an even curve.

I do lots of this stuff, I even have special tools for bending bar and strip and use this method most on smaller pieces.

Chunko'.

Similar threads

- Replies

- 7

- Views

- 766