David C

In Memorium

If I am not mistaken, this thread was about rescuing old tools where the back was in a dreadful state.

David C

David C

Mr_Grimsdale":36d6wk3s said:I am a bit mystified by the new Ray Iles OBM design with a rounded back. Can't be a good idea IMHO.

cheers

Jacob

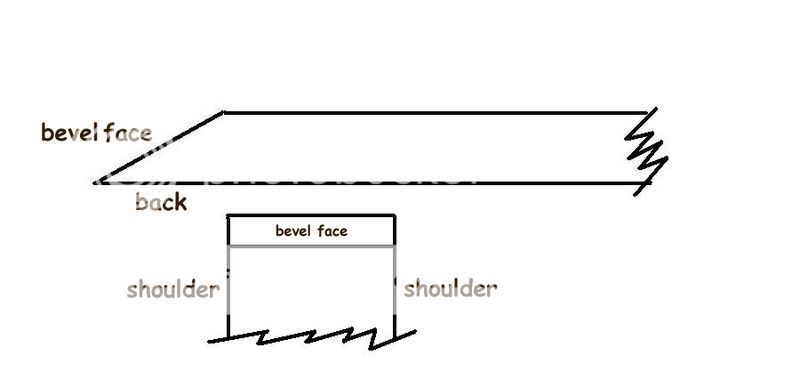

I was taught to call them face/back rather than back/front. As it seems more logical I thought I'd stick with it.Joel Moskowitz":eylqj6wu said:Mr_Grimsdale":eylqj6wu said:I am a bit mystified by the new Ray Iles OBM design with a rounded back. Can't be a good idea IMHO.

cheers

Jacob

Inless you are using the term "back" differently than i the backs of the Ray Iles Mortise chisels are flat. The front above the bevel are slightly rounded for comfort but they as they are above the bevel they do not interfere with cutting - and in fact are a historical detail you sometimes find on very old (18th century) mortise chisels.

Mr_Grimsdale":3qcicl2c said:"Tune" an OBM? :lol: :lol:

Just needs to be sharp. Doesn't matter about flat face, although needs to be geometrically regular in section as someone pointed out, otherwise it could twist I suppose.

I find all this tuning stuff a bit odd, it's as though every newly aquired tool should be re-machined as though it's just an unformed bit of steel.

In reality most things just need a quick sharpen and you are off. Rust and pitting disappear with use unless extreme.

PSHe's wrong, ideally the side are tapered, so not sqaure with the face, the back matters too i.e. has to be parallel to the face as the face/back wedging action is essential part of using an OBM, unlike most other chisels.Boggs: The bottom and sides of the blade

must be flat and square (the top of the blade is irrelevant).

I am a bit mystified by the new Ray Iles OBM design with a rounded back. Can't be a good idea IMHO.

cheers

Jacob

David C":2b8x8cdx said:If I am not mistaken, this thread was about rescuing old tools where the back was in a dreadful state.

David C

That's alright then if it keeps you happy :lol:mudman":37pf8hls said:snip

Chisels = knackered = lots of work to put right = satisfaction at end of day.

MikeW":2alzkzvc said:...

Back = ******

Face = ******

...

Beveled side

Non-beveled side

...

I think some of the confusion/argument is due to these definitions.

...

Take care, Mike

Agree. Same with plane blade, similar with saw i.e. back is opposite the cutting edge.MarcW":1p1vdsx0 said:snip

Face = non-beveled side, i.e. the side that has to be flattened

Cheers,

Marc

...The face of each chisel has an indentation point...

How is it possible to make such a common or garden task so blasted involved?

Enter your email address to join: