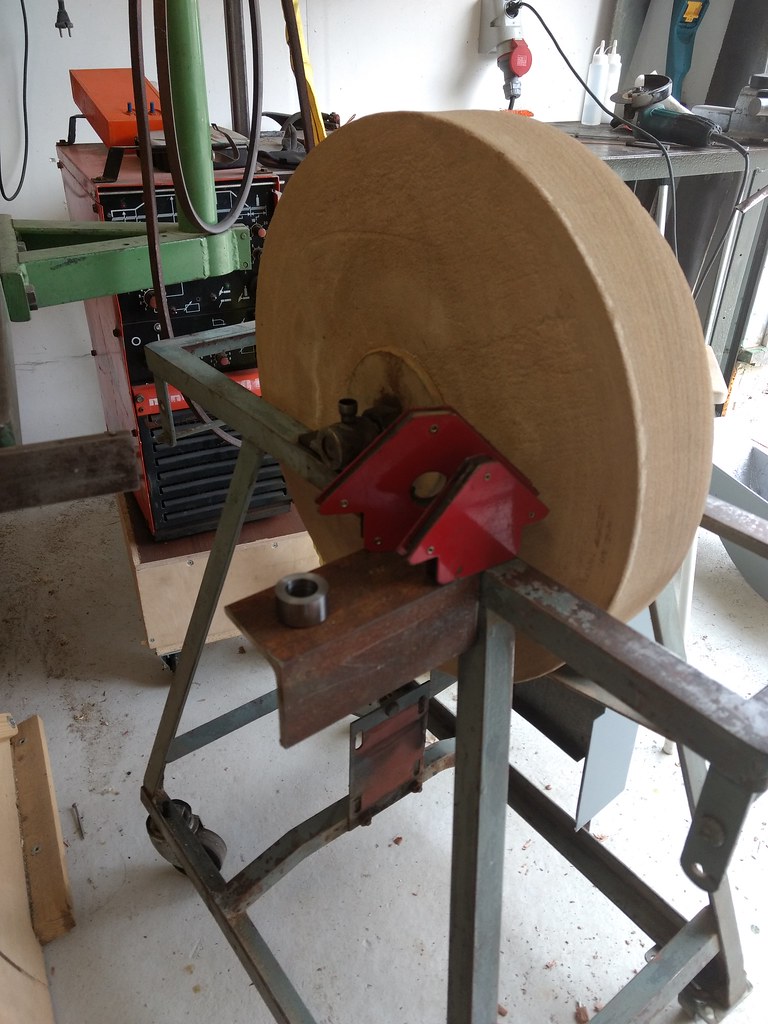

Well, just making this to show what I dragged home, an old sandstone grinder, working and with a 10x50cm wheel. For 50 euros I couldn't say no:

A pretty cool multiple pulley system here to keep the size down.

So now here's a sharpening system! At least for setting bevels and such. The plan is to refurbish it, add castor wheels, a tool rest that's compatible with tormek style jigs and true the stone. And a cover for the wheel when it's not in use.

We made a small mini vacation trip of this, though it wasn't far, maybe 50-60km, out in the archipelago in western finland. Pretty country out there, and connected with the longest suspension bridge in Finland I believe at a little over a kilometer:

A pretty cool multiple pulley system here to keep the size down.

So now here's a sharpening system! At least for setting bevels and such. The plan is to refurbish it, add castor wheels, a tool rest that's compatible with tormek style jigs and true the stone. And a cover for the wheel when it's not in use.

We made a small mini vacation trip of this, though it wasn't far, maybe 50-60km, out in the archipelago in western finland. Pretty country out there, and connected with the longest suspension bridge in Finland I believe at a little over a kilometer: