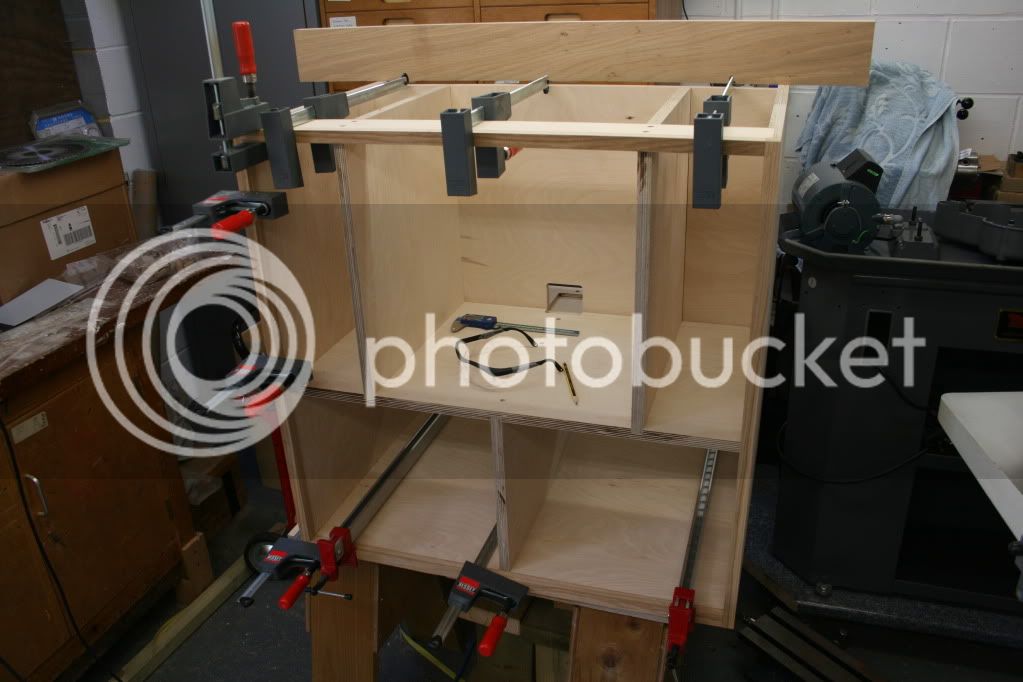

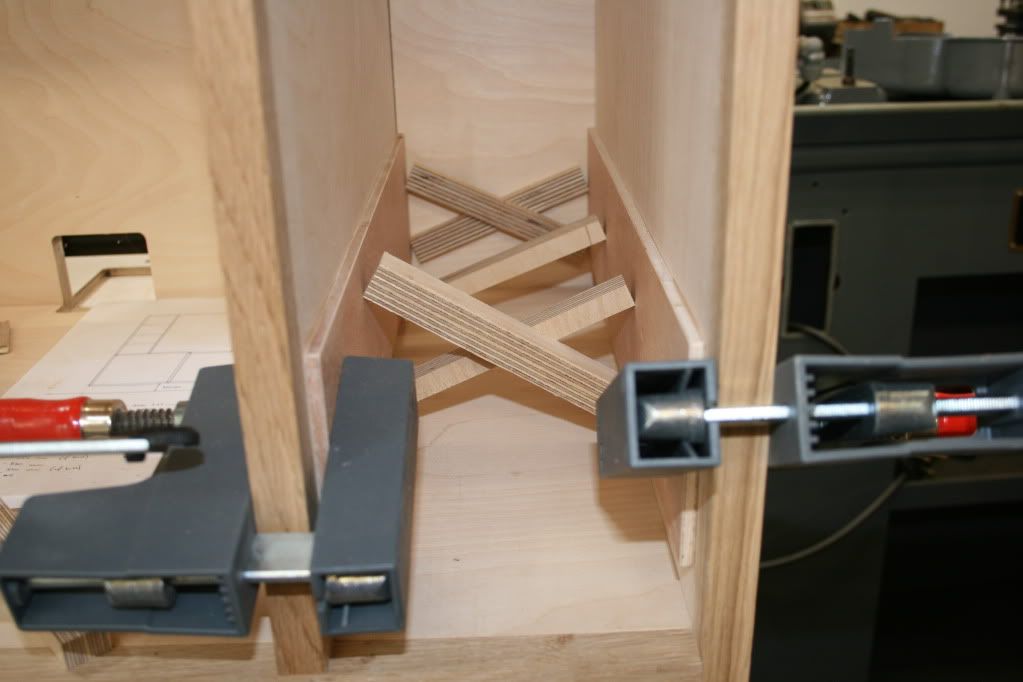

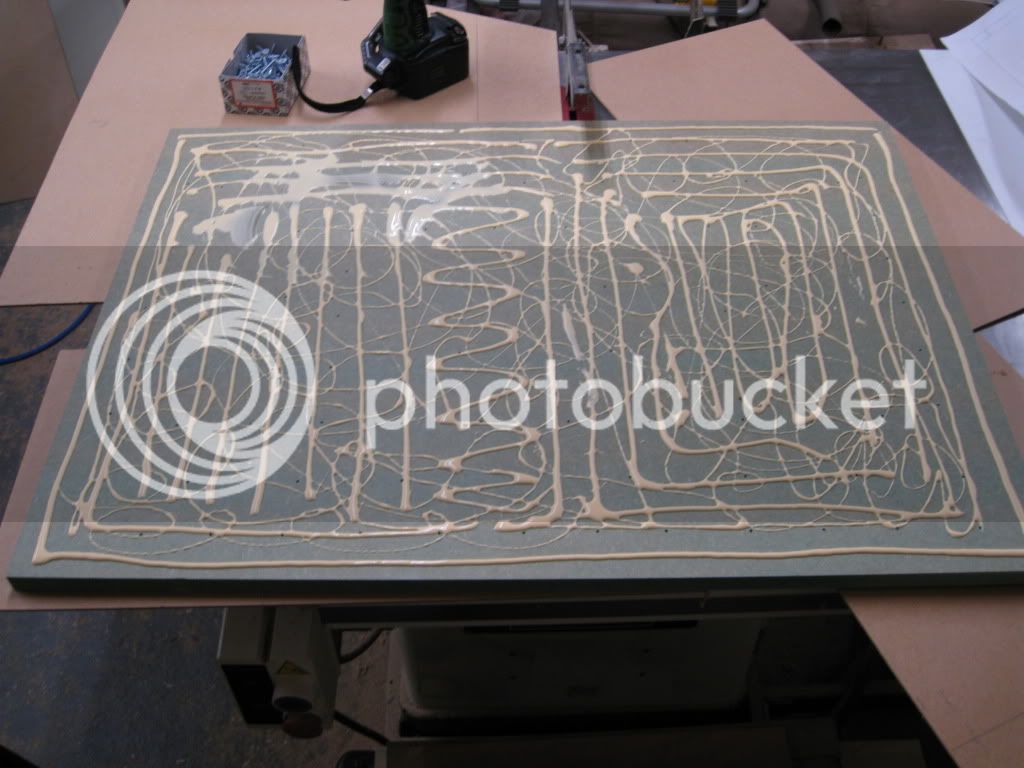

There have been a lot of these over the years. From that I have concluded its a good pretty good design so one I'm basing my design on, though there will be subtle differences. Its being built mainly from 18mm ply, oak trim, with a laminated MDF top. It will sit on casters and the final height is going to be a smidgen under the height of my table saw, so it can be used as part of the outfield support for that.

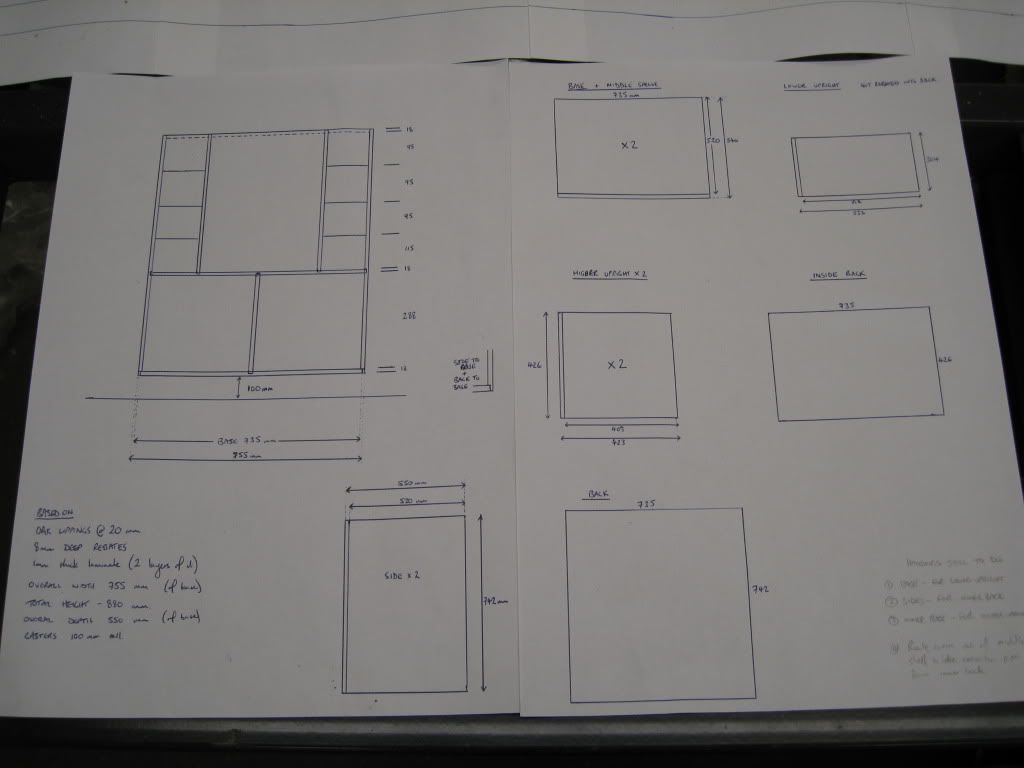

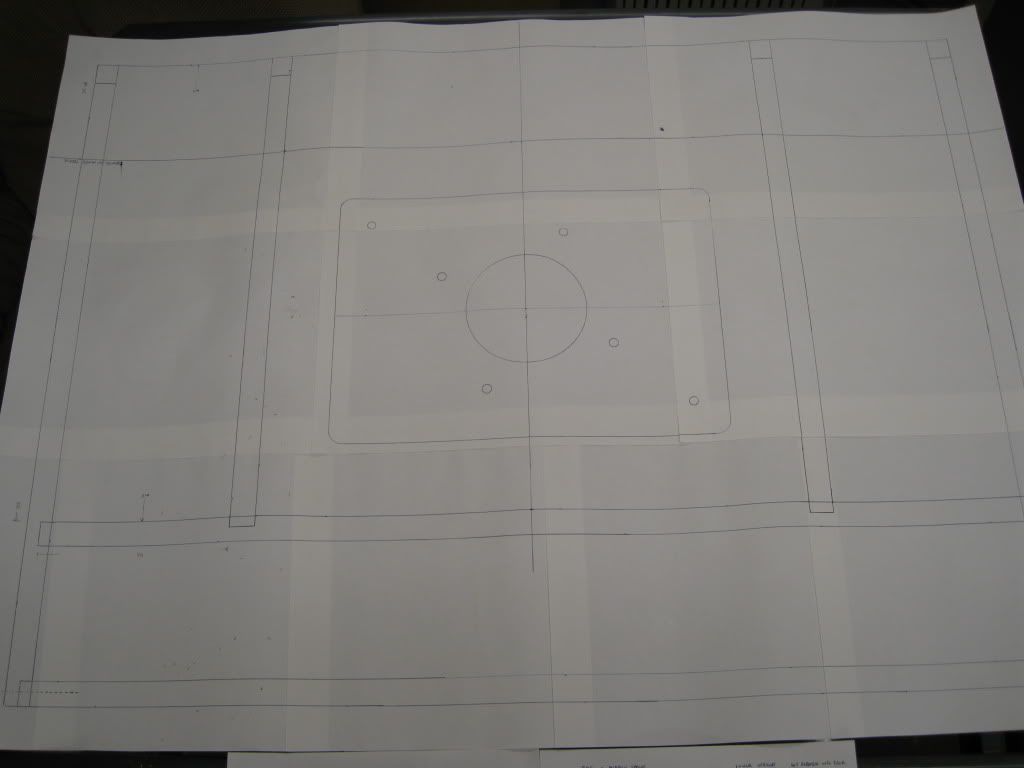

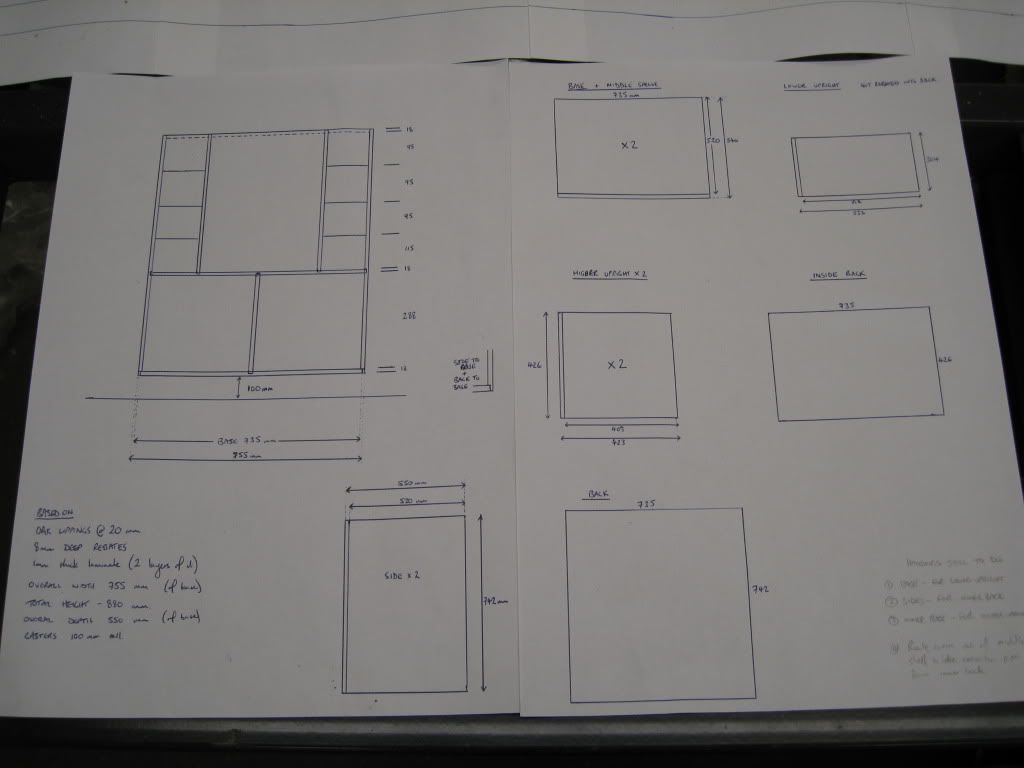

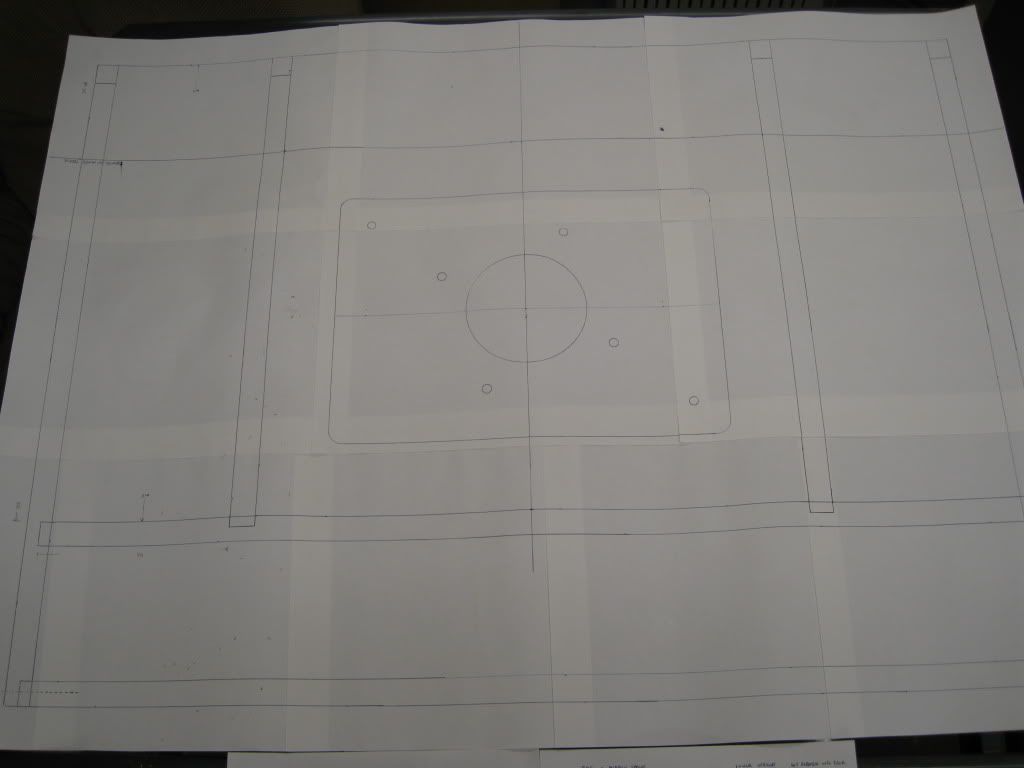

I started with some hand drawn plans, the cabinet drawn to scale and the top as a full size drawing. One day I will learn to use sketch up.

I started with some hand drawn plans, the cabinet drawn to scale and the top as a full size drawing. One day I will learn to use sketch up.