You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A few more wins

- Thread starter Pvt_Ryan

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

LuptonM

Established Member

LOL your going to have alot of planes

I think its good to learn how to fettle them so u could maintain planes but u don't need to keep buying planes in case u end up with an old stanley (you'd have to buy a USA one anyway)

I think its good to learn how to fettle them so u could maintain planes but u don't need to keep buying planes in case u end up with an old stanley (you'd have to buy a USA one anyway)

Pvt_Ryan

Established Member

I now have:

2x No 4

1x No 5

1x No 220

Block, Jack, Smoother. Just need a Jointer to get my basic set..

I just want a "set" of planes that I can get started with.. As per my wooden plane thread in "Design" I really want to make my own then I'll flog these ones (after I have restored them ofc).

My "dream" (if you will) is to make all of my own hand tools where possible. I know it's purest (mad) but I think it's kind of old skool, and if nothing else gives me a number of projects to start on.

Just got this as well:

http://cgi.ebay.co.uk/ws/eBayISAPI.dll? ... K:MEWNX:IT

2x No 4

1x No 5

1x No 220

Block, Jack, Smoother. Just need a Jointer to get my basic set..

I just want a "set" of planes that I can get started with.. As per my wooden plane thread in "Design" I really want to make my own then I'll flog these ones (after I have restored them ofc).

My "dream" (if you will) is to make all of my own hand tools where possible. I know it's purest (mad) but I think it's kind of old skool, and if nothing else gives me a number of projects to start on.

Just got this as well:

http://cgi.ebay.co.uk/ws/eBayISAPI.dll? ... K:MEWNX:IT

GazPal

Established Member

You're doing fine. You've essentially a basic set in the ones you have now and jointer choice depend on the scale of work you'll be carrying out or involved with, but - more importantly - what you're comfortable using ........ This can be anything between a #05.1/2, #06, #07 and #08.

All I'd consider adding - for the time being - would be a rebate/fillister and a small bull-nosed shoulder plane. Without needing to break the bank these could be a Record #078/#778 and #077A. Woden and WS produced some nice fillisters.

Then router planes #071, #722, scraper plane #081 and spokeshaves #A151R & A151 (Convex and flat).......... the list goes on. :wink:

--------

Do you intend to make your own planes using metal or timber?

All I'd consider adding - for the time being - would be a rebate/fillister and a small bull-nosed shoulder plane. Without needing to break the bank these could be a Record #078/#778 and #077A. Woden and WS produced some nice fillisters.

Then router planes #071, #722, scraper plane #081 and spokeshaves #A151R & A151 (Convex and flat).......... the list goes on. :wink:

--------

Do you intend to make your own planes using metal or timber?

Lardman

Established Member

Head first down the slope pvt_Ryan  a #5 1/2 would be nice, I picked one up last week for jointing its man enough plane for me.

a #5 1/2 would be nice, I picked one up last week for jointing its man enough plane for me.

Pvt_Ryan

Established Member

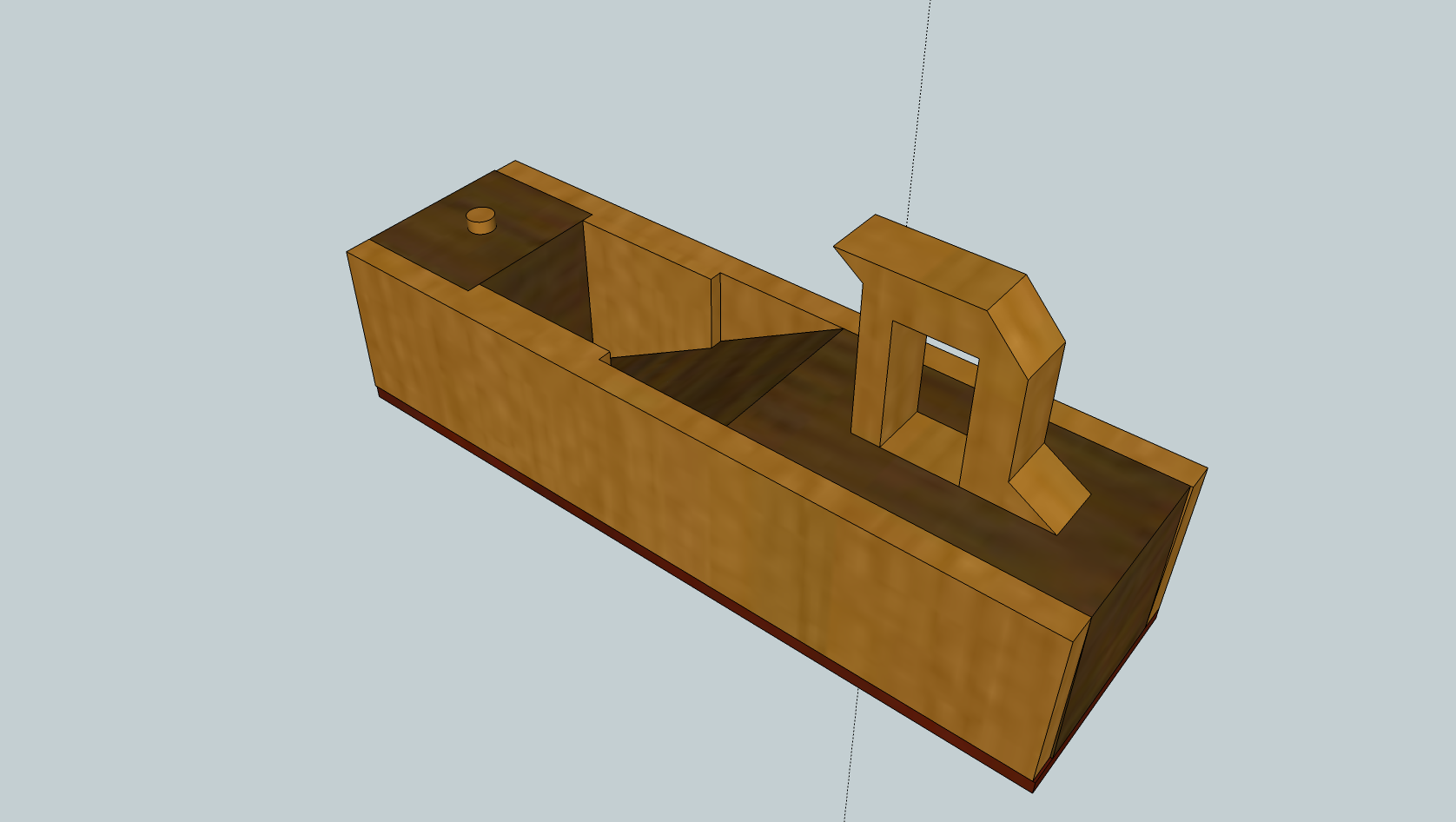

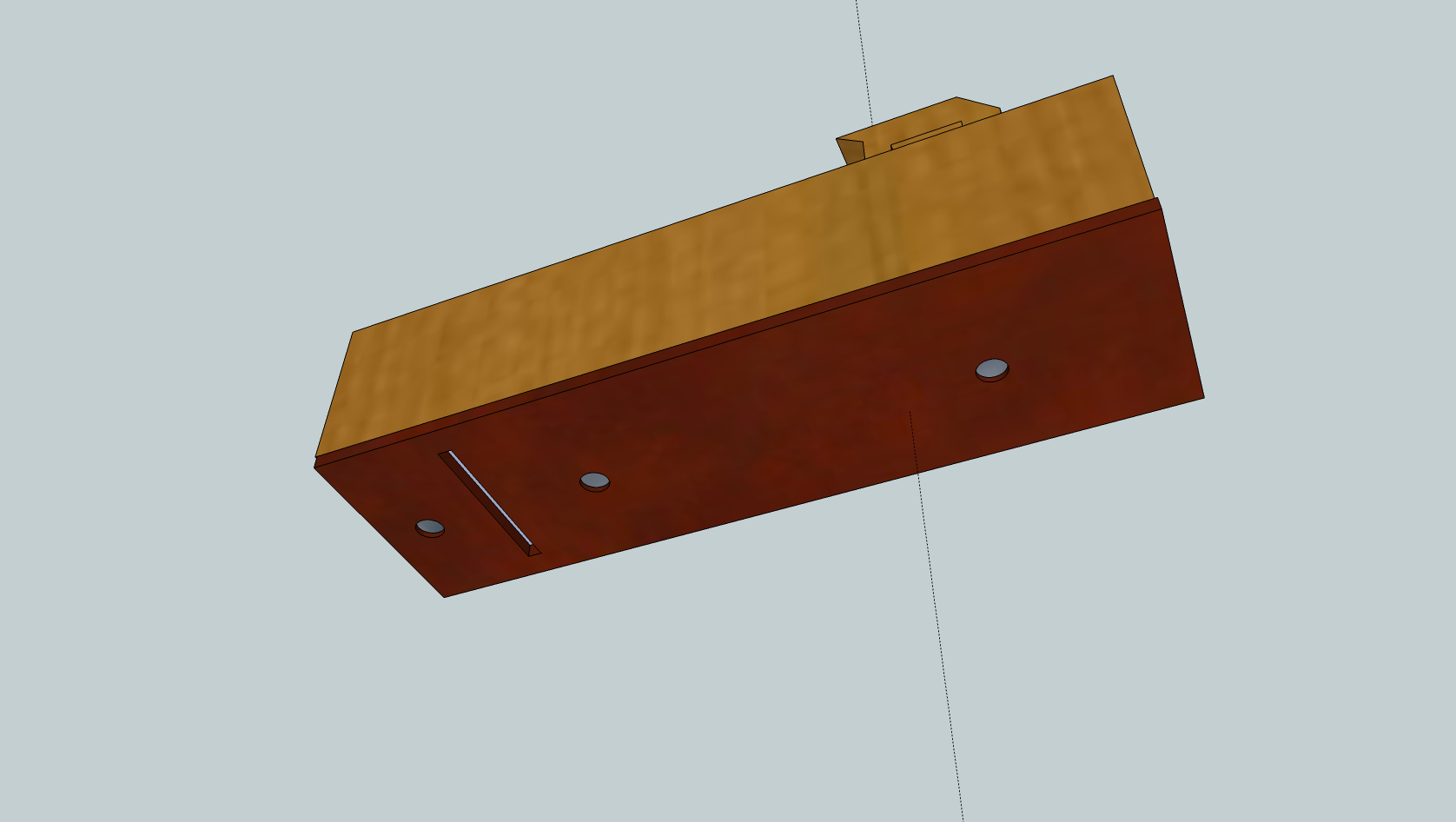

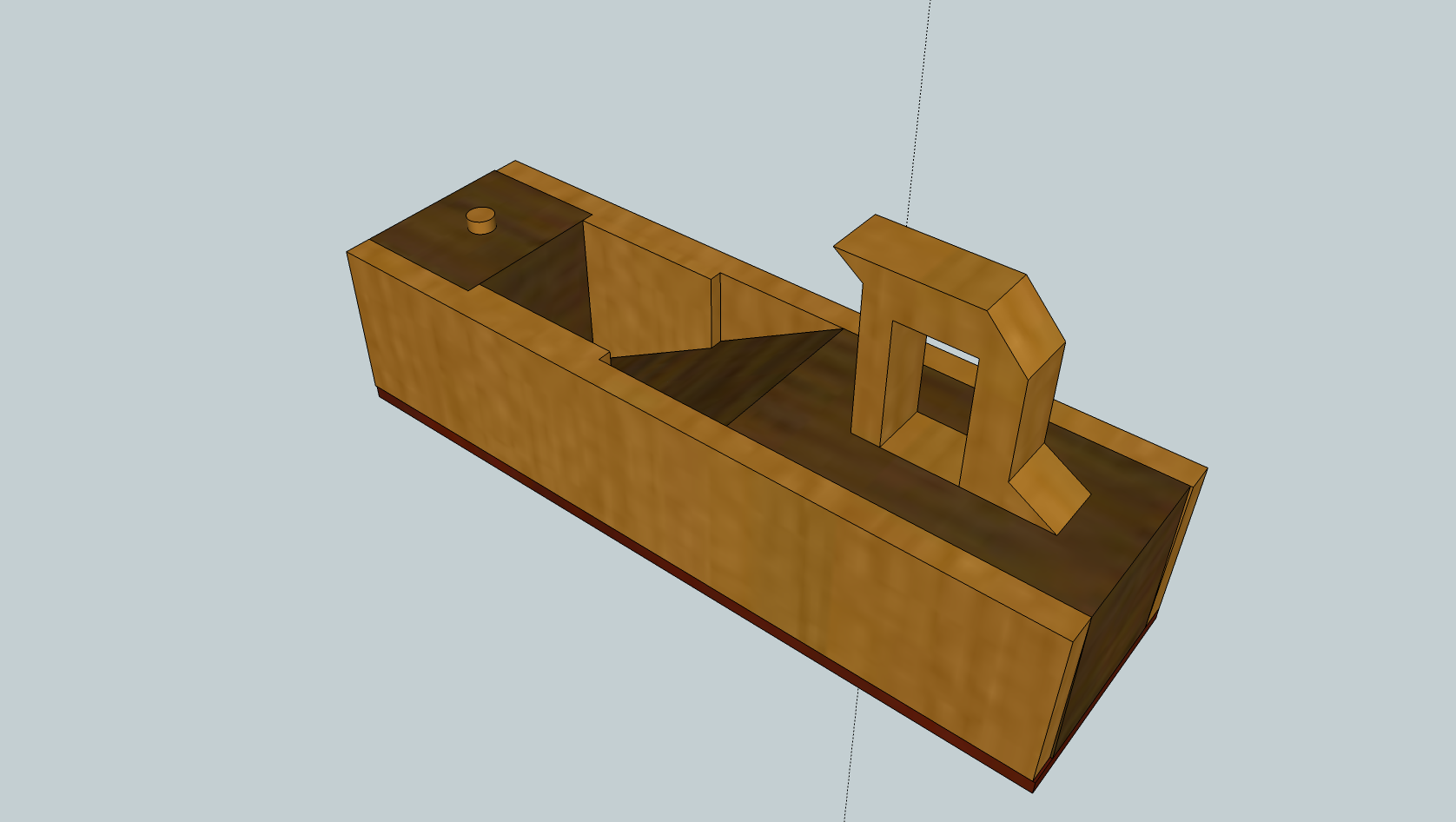

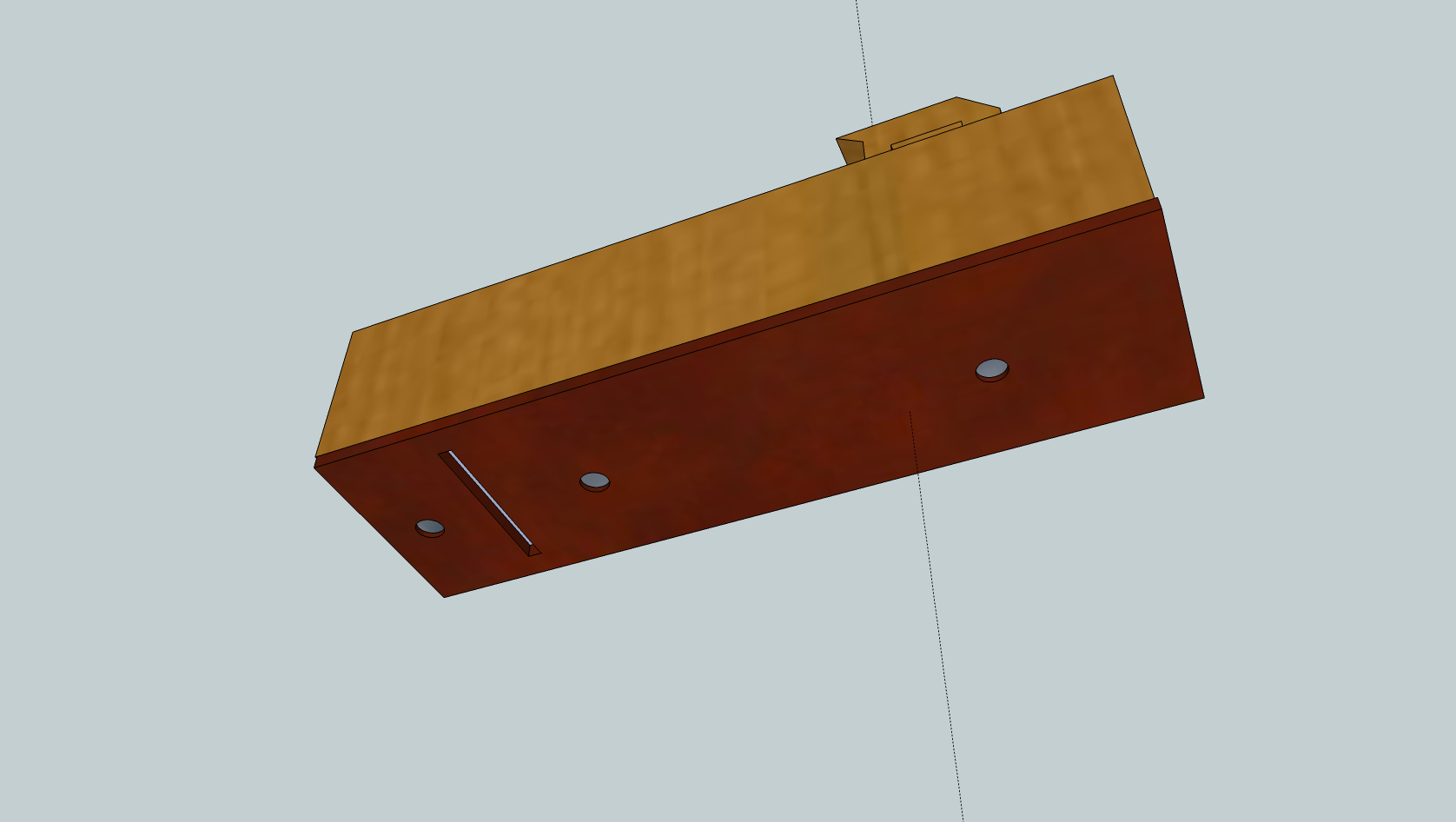

I know.. I have this mad vision of a plane in my head..

I was thinking:

Base - Sapele

Sides, Handle & strike nut - Maple

Infill & Wedge - Walnut

the base can be secured to the infill with 2 screws counter sunk into it so it can be replaced easily if needed.

My logic:

Sapele for the base as it is hard wearing.

Infill and wedge Walnut as it polishes up good and is a nice dark wood.

Sides, handle & strike nut maple as the lightness adds contrast to the dark infill

What do you all think?

I was thinking:

Base - Sapele

Sides, Handle & strike nut - Maple

Infill & Wedge - Walnut

the base can be secured to the infill with 2 screws counter sunk into it so it can be replaced easily if needed.

My logic:

Sapele for the base as it is hard wearing.

Infill and wedge Walnut as it polishes up good and is a nice dark wood.

Sides, handle & strike nut maple as the lightness adds contrast to the dark infill

What do you all think?

clewlowm

Established Member

i think you are bucking fonkers

GazPal

Established Member

Pvt_Ryan":2zdxuiq2 said:I know.. I have this mad vision of a plane in my head..

I was thinking:

Base - Sapele

Sides, Handle & strike nut - Maple

Infill & Wedge - Walnut

the base can be secured to the infill with 2 screws counter sunk into it so it can be replaced easily if needed.

My logic:

Sapele for the base as it is hard wearing.

Infill and wedge Walnut as it polishes up good and is a nice dark wood.

Sides, handle & strike nut maple as the lightness adds contrast to the dark infill

What do you all think?

I take it you mean to build a wooden plain. If so, I'd consider a well quartered Rosewood or Ebony sole and Beech top end, with stainless striker button at the heel.

Richard T

Established Member

Pvt Ryan wrote:

I was thinking:

Base - Sapele

Sides, Handle & strike nut - Maple

Infill & Wedge - Walnut

There's something missing here .... Iron! That's it. Old one? New one?

I was thinking:

Base - Sapele

Sides, Handle & strike nut - Maple

Infill & Wedge - Walnut

There's something missing here .... Iron! That's it. Old one? New one?

Pvt_Ryan

Established Member

@clewlowm Why?

@GazPal - Why? (As you no doubt guessed I am new to the scene)

@Richard T - Well I do have 1 spare blade and one in a no 4 that I am not sure I am going to use so I can use the blade elsewhere so I would just re-purpose those initially but if needed I can buy new irons.. I'd rather not make my own just yet (again lack of experience)

@GazPal - Why? (As you no doubt guessed I am new to the scene)

@Richard T - Well I do have 1 spare blade and one in a no 4 that I am not sure I am going to use so I can use the blade elsewhere so I would just re-purpose those initially but if needed I can buy new irons.. I'd rather not make my own just yet (again lack of experience)

Richard T

Established Member

If I were to make a wooden plane, I think I would choose an iron that had been made for a wooden plane - boot sale no-hopers for a couple of quid can often yield some great old steel with a famous old name on.

Though it saves anawfullot of time and swearing to check that the backs are rust pit free.

Though it saves anawfullot of time and swearing to check that the backs are rust pit free.

Pvt_Ryan

Established Member

What is the difference in the iron?

Surely if I have a blade, I make sure it fits the mouth and frog (is that the correct term for a wooden plane?) and it's sharp then it will work fine..

Surely if I have a blade, I make sure it fits the mouth and frog (is that the correct term for a wooden plane?) and it's sharp then it will work fine..

GazPal

Established Member

Pvt_Ryan":137mhcc9 said:@GazPal - Why? (As you no doubt guessed I am new to the scene)

Personal preferences really.

Hardwearing and dense Rosewood or Ebony (I'd choose Rosewood before Ebony), dense Beech, a non-rusting stainless striker that won't distort/take damage easily during use. All lend themselves to a good wooden plane with reasonable heft.

Countersunk screws can sometimes snag wood fragments/shavings as you work and this can sometimes prove problematical in terms of damage to the surface being work.

Single pre-WWII clean laminated & tapered handplane irons can be had from a few old stock supplies that turn up from time to time and they're well worth seeking out for projects like this. They're constructed by forge welding a section of high carbon steel (Edge) onto a main body of milder steel.:wink:

Alf

Established Member

For the first one I'd suggest less expensive materials. There will be a learning curve.

Pvt_Ryan

Established Member

@Alf I have loads of pine from a futon that I was getting rid of so I am going to do a complete mock up before I even buy the expensive wood.

@GazPal how would you attach the sole?

Here is a mock up:

@GazPal how would you attach the sole?

Here is a mock up:

big soft moose

Established Member

- Joined

- 22 May 2008

- Messages

- 5,079

- Reaction score

- 0

I dont know a huge ammount about this, but i think you are asking for trouble fixing a sole on

if you look at the philly planes for example they seem to be made oout of a block of wood, or two/three bits jointedto gether with the sole intgeral to the body

if you look at the philly planes for example they seem to be made oout of a block of wood, or two/three bits jointedto gether with the sole intgeral to the body

Pvt_Ryan

Established Member

hmm.. Interesting..

I was making the sole removeable as I thought I saw that somewhere else and if it's not removable any lapping (or general wear and tear) of the sole will widen the mouth.

I was making the sole removeable as I thought I saw that somewhere else and if it's not removable any lapping (or general wear and tear) of the sole will widen the mouth.

GazPal

Established Member

Pvt_Ryan":3nhddrwj said:hmm.. Interesting..

I was making the sole removeable as I thought I saw that somewhere else and if it's not removable any lapping (or general wear and tear) of the sole will widen the mouth.

There's absolutely nothing wrong with attaching a removable or permanent harder wearing sole. Detachable ones tend to be found when viewing those used by patternmakers, but they're most often made to differing radii for convex and concave work. I have a few myself.

It takes quite a while for one to wear a decent hardwood sole down to the point of needing a re-dress, but if a laminated sole does need replacing it's simple enough to do so via a little reverse engineering. :wink:

Jack in Nepean

Established Member

You might wish to consider something like the one built by my friend and noted in this: http://forum.canadianwoodworking.com/sh ... hp?t=35567

Pvt_Ryan

Established Member

Nice, I am gonna steal that design..