fezman

Established Member

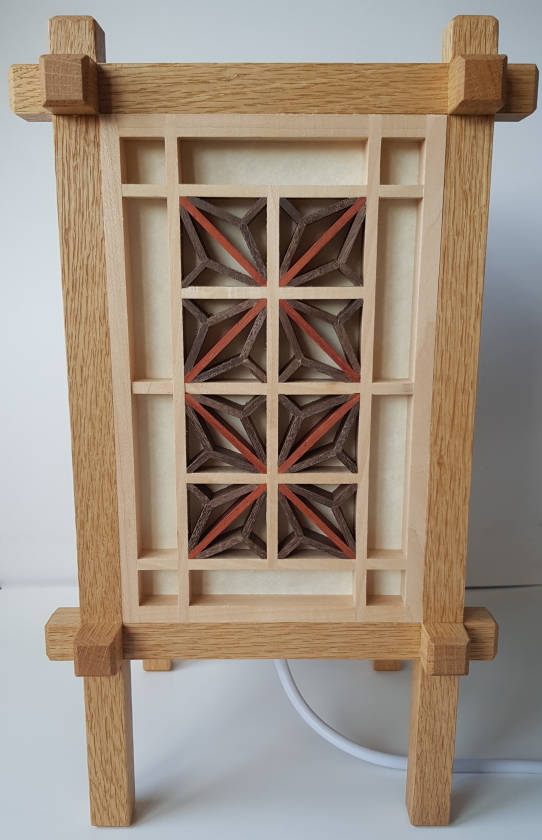

Just before Christmas, my Mum was using an old shoe box to store the nic nacs she uses regularly. Lets just say the shoe box had seen better days.

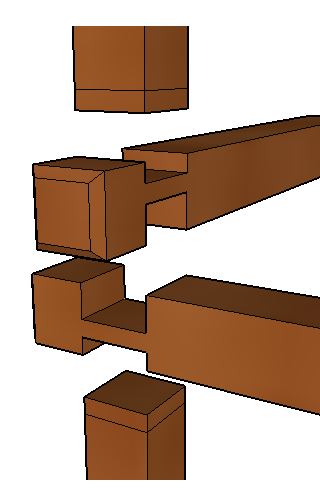

So she asked for a simple box, of similar dimensions. Now the box lives at the side of, but just under a small chair, so a hinged lid was out of the question. I'd not done any DT's for a while so put this together as much for practice as anything. It's European Pippy Oak, with ABW strips. Finish is Osmo PolyX Clear Gloss.

So she asked for a simple box, of similar dimensions. Now the box lives at the side of, but just under a small chair, so a hinged lid was out of the question. I'd not done any DT's for a while so put this together as much for practice as anything. It's European Pippy Oak, with ABW strips. Finish is Osmo PolyX Clear Gloss.