DavidE

Established Member

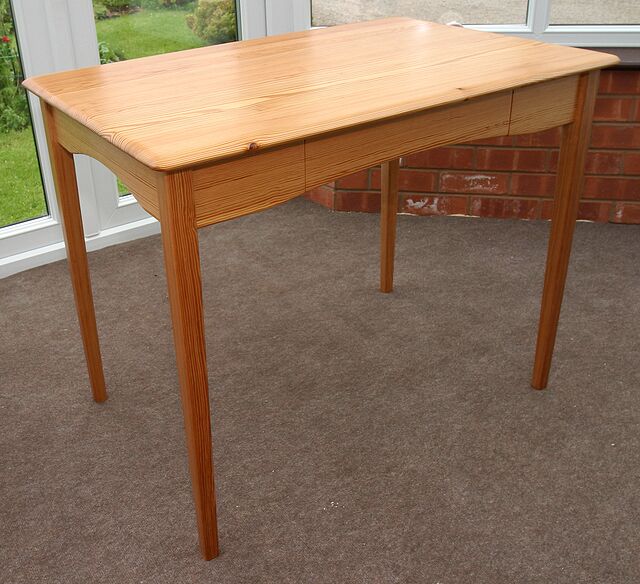

I posted on the design forum a while back about a design for a writing desk.

Well I've finally finished the desk and taken some photos I didn't take many WIP photos as I've not got much room at the moment!

It uses the Blumotion runners which I also got some help on from posts on the forum.

Here's the pictures - thanks to the forum again for the help along the way.

The wood is Pitch Pine (from recycled Pews). The finish is more polished, however, I used a Polarising filter to cut the nasty reflections out.

Cheers

David

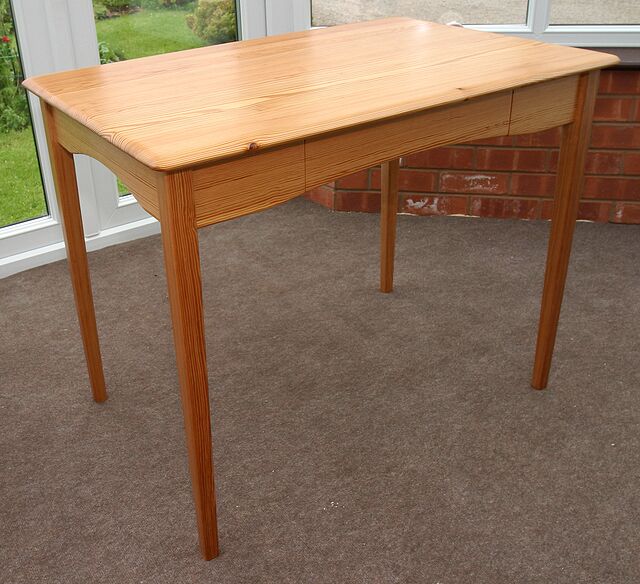

Well I've finally finished the desk and taken some photos I didn't take many WIP photos as I've not got much room at the moment!

It uses the Blumotion runners which I also got some help on from posts on the forum.

Here's the pictures - thanks to the forum again for the help along the way.

The wood is Pitch Pine (from recycled Pews). The finish is more polished, however, I used a Polarising filter to cut the nasty reflections out.

Cheers

David