I have been asked to install newel posts, handrail and spindles onto an existing staircase which has short stubbie newel posts and im assuming a mopstick style handrail screwed to the wall.

I was thinking of doweling the new newel posts down on the old short ones with lots of glue. Although i did use some 20mm steel bar once on a gate post repair and that seemed really solid so may use that instead of a wooden dowel??

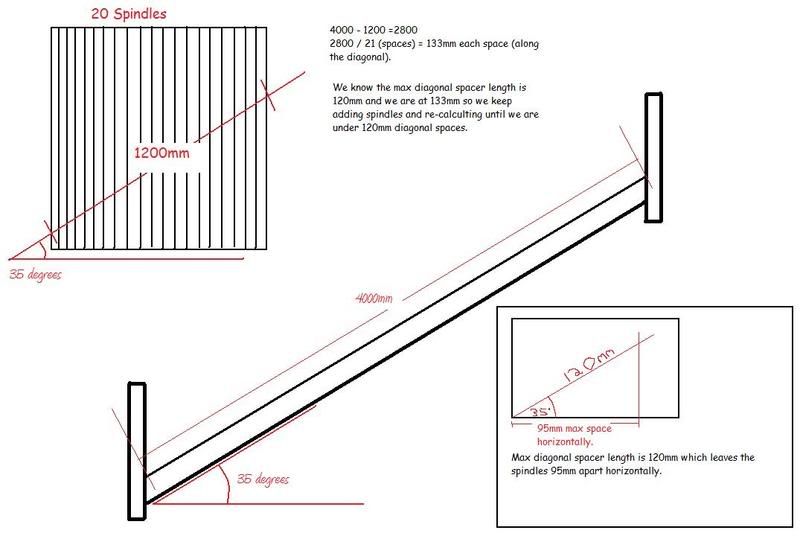

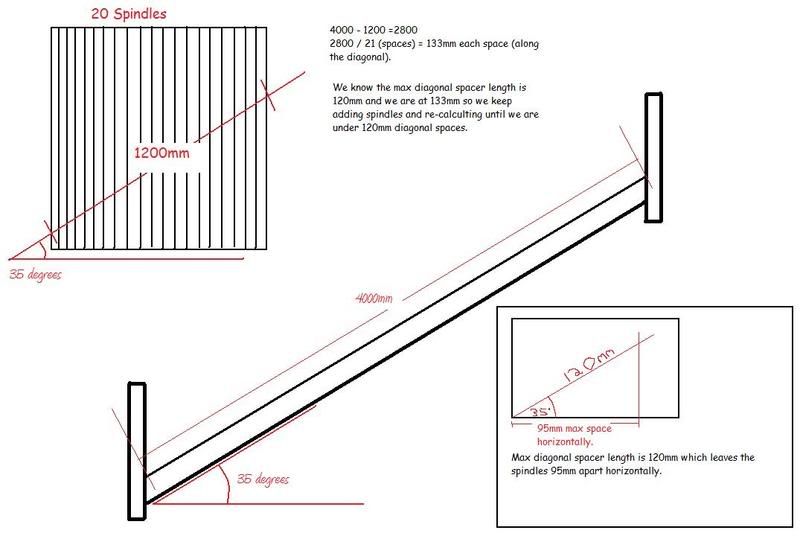

Then handrail fitted as normal into new posts. Now i was taught how to work out diagonal spacer lengths for spindles at college but i cant for the life of me remember the formula so i have come up with a method myself but im not sure how accurate would be so any comments would be great. I would work out the angle of the string using my roofing square and a level and a bit of board. For now i'm saying the string is at 35 degrees.

Has anyone got a guide to fitting out stairs from strings upwards?

Thanks for any input!

Simon.

I was thinking of doweling the new newel posts down on the old short ones with lots of glue. Although i did use some 20mm steel bar once on a gate post repair and that seemed really solid so may use that instead of a wooden dowel??

Then handrail fitted as normal into new posts. Now i was taught how to work out diagonal spacer lengths for spindles at college but i cant for the life of me remember the formula so i have come up with a method myself but im not sure how accurate would be so any comments would be great. I would work out the angle of the string using my roofing square and a level and a bit of board. For now i'm saying the string is at 35 degrees.

Has anyone got a guide to fitting out stairs from strings upwards?

Thanks for any input!

Simon.