Zeddedhed

Established Member

First a little bit of introduction......

A few months ago I bought one of these..

and one of these

all for just under £150 (a bit a bargain methinks).

I also got myself a set of Axminster HSS tools and a copy of Keith Rowleys book.

Since then I've made one of these...

One of these...

a bunch of these

and for a bit of a laugh one of these... (it works by the way)

Then I went to the D&M tool show and watched a demo by a mad man from Record and understood how sharp the tools need to be.

I dug out the bench grinder, sparks flew in the right places and I found out I could make square things round without needing a change of underpants.

More practice with the roughing gouge followed until I cold do this fairly easily

Then I had a go with an oval skew and changed my pants.

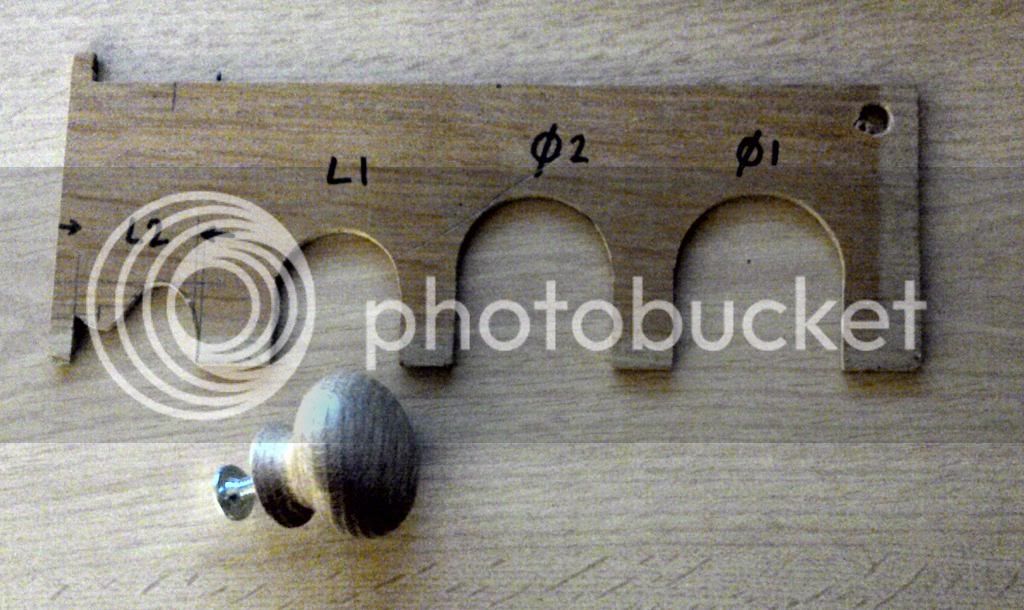

Anyway, I now want to try and make some small knobs for tools and furniture pieces.

I'm guessing that the right thing to do is to use my lovely chuck but despite reading and watching for the last few days can't find much info on actually using the damned things.

I understand that they can grip wood in compression or expansion via a tenon or 'mortice', dovetailed or parallel depending on the jaws.

I've also seen some vids of people doing this

Is this OK?

What is the normal procedure for turning a knob?

Any help (or weeping and wailing) accepted

A few months ago I bought one of these..

and one of these

all for just under £150 (a bit a bargain methinks).

I also got myself a set of Axminster HSS tools and a copy of Keith Rowleys book.

Since then I've made one of these...

One of these...

a bunch of these

and for a bit of a laugh one of these... (it works by the way)

Then I went to the D&M tool show and watched a demo by a mad man from Record and understood how sharp the tools need to be.

I dug out the bench grinder, sparks flew in the right places and I found out I could make square things round without needing a change of underpants.

More practice with the roughing gouge followed until I cold do this fairly easily

Then I had a go with an oval skew and changed my pants.

Anyway, I now want to try and make some small knobs for tools and furniture pieces.

I'm guessing that the right thing to do is to use my lovely chuck but despite reading and watching for the last few days can't find much info on actually using the damned things.

I understand that they can grip wood in compression or expansion via a tenon or 'mortice', dovetailed or parallel depending on the jaws.

I've also seen some vids of people doing this

Is this OK?

What is the normal procedure for turning a knob?

Any help (or weeping and wailing) accepted

Attachments

-

Round things 2.jpg241.1 KB · Views: 1,209

Round things 2.jpg241.1 KB · Views: 1,209 -

Screenshot 2015-10-21 08.28.29.png149.6 KB · Views: 1,209

Screenshot 2015-10-21 08.28.29.png149.6 KB · Views: 1,209 -

Round things 6.jpg240.5 KB · Views: 1,209

Round things 6.jpg240.5 KB · Views: 1,209 -

Round things 5.jpg244 KB · Views: 1,209

Round things 5.jpg244 KB · Views: 1,209 -

Round things 3.jpg243.9 KB · Views: 1,209

Round things 3.jpg243.9 KB · Views: 1,209 -

Round things 7.jpg242.1 KB · Views: 1,209

Round things 7.jpg242.1 KB · Views: 1,209 -

Round things 4.jpg242.4 KB · Views: 1,209

Round things 4.jpg242.4 KB · Views: 1,209 -

Round things 1.jpg243.3 KB · Views: 1,209

Round things 1.jpg243.3 KB · Views: 1,209