gasman

Established Member

I have been commissioned to make a wooden cross. It will be about 1400 x 600, in oak and will be on an external wall

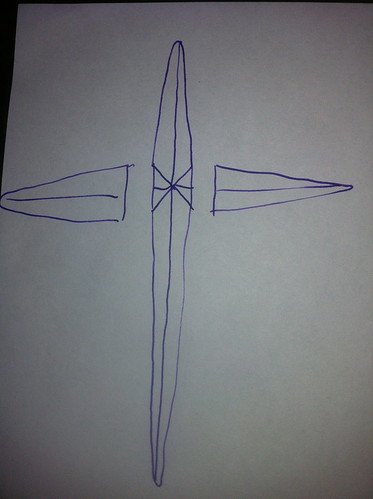

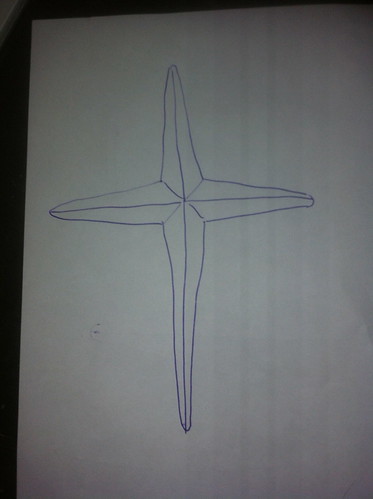

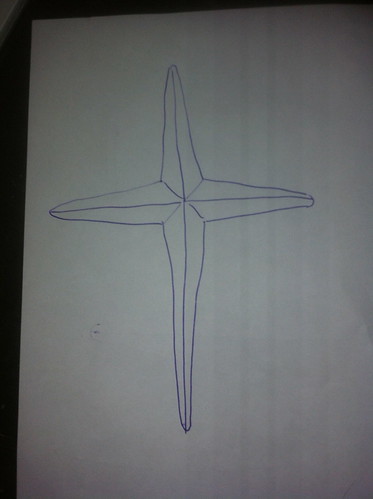

The design brief is a bit like this rough diagram

Ideally the back looks exactly like the front

At the widest each limb needs to be about 125mm wide and about 62.5 thick. Each limb is bevelled almost to an edge. So in cross section each limb is a diamond shape - tapering down to about 30mm at the very 'tip' of each limb

It would be reasonably straightforward to make 4 separate limbs which fitted together at a complex 'x' joint in the centre but as it is going to be exposed to the elements it would surely move and the joints would open up.

So in an ideal world it would be just 2 pieces which fitted together but I cannot see how this is possible with the bevelled edges as they are.

The best I can think of is to do the long limb as one piece and then have the minor limbs attached to each side - and I could add a rebated joint at the back to increase the strength so I could get some fixation in there too - maybe a dowel or two

Anyone got any better ideas - it is doing my head in a bit. I have started mocking up a 1/3 scale version but it is still not very clear

Thanks a lot

Mark

The design brief is a bit like this rough diagram

Ideally the back looks exactly like the front

At the widest each limb needs to be about 125mm wide and about 62.5 thick. Each limb is bevelled almost to an edge. So in cross section each limb is a diamond shape - tapering down to about 30mm at the very 'tip' of each limb

It would be reasonably straightforward to make 4 separate limbs which fitted together at a complex 'x' joint in the centre but as it is going to be exposed to the elements it would surely move and the joints would open up.

So in an ideal world it would be just 2 pieces which fitted together but I cannot see how this is possible with the bevelled edges as they are.

The best I can think of is to do the long limb as one piece and then have the minor limbs attached to each side - and I could add a rebated joint at the back to increase the strength so I could get some fixation in there too - maybe a dowel or two

Anyone got any better ideas - it is doing my head in a bit. I have started mocking up a 1/3 scale version but it is still not very clear

Thanks a lot

Mark