Hi all,

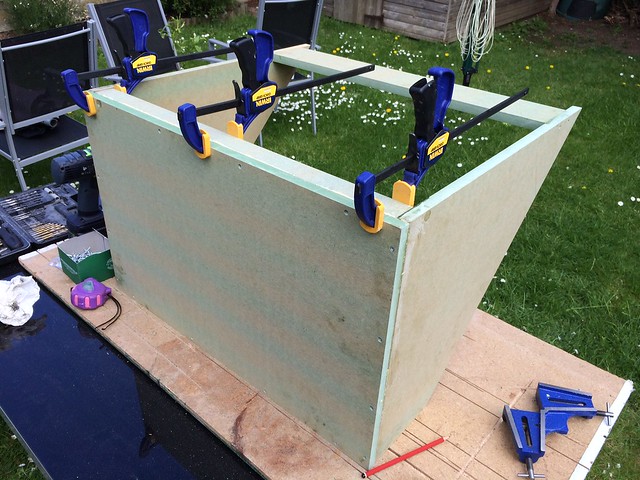

I've been working on this storage for about a month now, on and off, and thought I would share a mini blog on its progress so far. I've enjoyed reading others, and am always amazed at the quality of what I see. Hopefully by sharing this, I can learn new ways and methods from some of your replies.

Woodworking Background

I studied 'Restistant Materials' at School - which is basically woodwork with a little bit of plastic work thrown in also. My GCSE project was a disaster, and ended up as a pile of scrapwood in a tray - somehow I still managed to get a 'B'.

I don't think I ever really touched a piece of wood again until 2012 when my wife and I purchased our first home. The house was (is) in a big mess, and needed a lot of work. Our first task was to replace the bathroom - which was leaking into the kitchen. With the encouragement and (massive amounts of) help of my brothers, and a friend that could tile we did everything from moving pipes, installing a new shower, new suite etc. It was at this point that my confidence in DIY grew, and I realised that certain tasks I could do myself, and enjoy, rather than bringing in the professionals.

The next room to tackle was the lounge diner - spending all evening cooped up in the bedroom, eating, watching TV soon grew tiresome, so we needed somewhere to spend some time and chill out. After removing the old wall paper, it was clear that the walls werent in the best of condition. and would need a skim. So after removing the old skirting, architrave and coving, the plasterer was in. Fitting the new (mdf) skirting / architrave was my first attempt at anything to do with wood. After careful planning and research it managed to go pretty well, and i'm still very pleased with how it looks. The Evolution mitre saw, whilst not entirely accurate really helped me get the results I was looking for.

After doing the same procedure in the bedroom, the next project I undertook was creating a table for the mitre saw - just to make it that much more easier to use. I don't have a lot of pictures, but here is the finished result:

My real project that I am working towards is a Cedar Strip Canoe - i've done a lot of research on it so far, and other than having the time, or space in the garage to do it, i'm pretty much ready to start. In preparation for the Canoe, I have been buying a few powertools over the last year - a Jigsaw and a RO Sander were one of the first purchases. Having a very understanding wife, and a very strong philosophy of buying once, buying right, I decided to head down the festool route. My other really bad habbit (OCD?) is that I like to have things matching. So once I had got the Festool ETS 150 and the Carvex 420, I couldn't choose any other brand for my replacement drill, circular saw and extractor. I know they are all massively OTT for my needs, but I enjoy using them, and will hopefully last me for a lifetime.

I've been working on this storage for about a month now, on and off, and thought I would share a mini blog on its progress so far. I've enjoyed reading others, and am always amazed at the quality of what I see. Hopefully by sharing this, I can learn new ways and methods from some of your replies.

Woodworking Background

I studied 'Restistant Materials' at School - which is basically woodwork with a little bit of plastic work thrown in also. My GCSE project was a disaster, and ended up as a pile of scrapwood in a tray - somehow I still managed to get a 'B'.

I don't think I ever really touched a piece of wood again until 2012 when my wife and I purchased our first home. The house was (is) in a big mess, and needed a lot of work. Our first task was to replace the bathroom - which was leaking into the kitchen. With the encouragement and (massive amounts of) help of my brothers, and a friend that could tile we did everything from moving pipes, installing a new shower, new suite etc. It was at this point that my confidence in DIY grew, and I realised that certain tasks I could do myself, and enjoy, rather than bringing in the professionals.

The next room to tackle was the lounge diner - spending all evening cooped up in the bedroom, eating, watching TV soon grew tiresome, so we needed somewhere to spend some time and chill out. After removing the old wall paper, it was clear that the walls werent in the best of condition. and would need a skim. So after removing the old skirting, architrave and coving, the plasterer was in. Fitting the new (mdf) skirting / architrave was my first attempt at anything to do with wood. After careful planning and research it managed to go pretty well, and i'm still very pleased with how it looks. The Evolution mitre saw, whilst not entirely accurate really helped me get the results I was looking for.

After doing the same procedure in the bedroom, the next project I undertook was creating a table for the mitre saw - just to make it that much more easier to use. I don't have a lot of pictures, but here is the finished result:

My real project that I am working towards is a Cedar Strip Canoe - i've done a lot of research on it so far, and other than having the time, or space in the garage to do it, i'm pretty much ready to start. In preparation for the Canoe, I have been buying a few powertools over the last year - a Jigsaw and a RO Sander were one of the first purchases. Having a very understanding wife, and a very strong philosophy of buying once, buying right, I decided to head down the festool route. My other really bad habbit (OCD?) is that I like to have things matching. So once I had got the Festool ETS 150 and the Carvex 420, I couldn't choose any other brand for my replacement drill, circular saw and extractor. I know they are all massively OTT for my needs, but I enjoy using them, and will hopefully last me for a lifetime.