A copy of 'Mouldings in Practice' by Matthew Sheldon Bickford would be a good investment. It's not a cheap book, but is by far and away the best reference work on hand-cut mouldings I've come across. Classic Hand Tools and (possibly) Axminster can supply, but Amazon don't stock it.

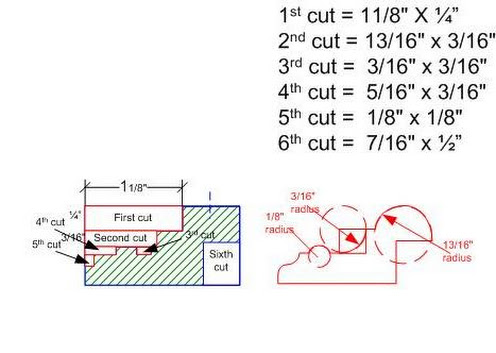

Buying hollows and rounds can be a bit of a nightmare. The numbering system for H&R's is a pain - the number corresponds to the radius of circle in 16ths of an inch up to about 10, then wanders off. Different makers used slightly different numbering systems over the years, so a no. 12 hollow may not match another maker's no 12 round. Buying matched pairs is safest, but you pay a premium. They start at no. 1 (1/16") and the largest usually found is a no.18 (my 18 round is 1 1/2") but even bigger ones occasionally turn up. Cabinetmakers would probably use mostly smaller sizes, architectural joiners would use the larger sizes of plane more often. (However just because your drawing shows a 13/16" radius feature doesn't necessarily mean that a no. 13 hollow will fit it!)

According to Matt Bickford, you don't need every size (or even every alternate size, as in a 'half-set') to cut a great variety of mouldings. However, there are a few pitfalls - the H&R's can't do it all, and sometimes have to be supplemented by side rounds, snipe bills and side rebates. These latter tend to be scarcer secondhand, and good pairs fetch silly prices. (An iron side rebate would serve, but there's no real modern substitute for the snipe bills and side rounds.)

One advantage of hand-cut mouldings over machine-cut (according to Mr. Bickford) is that the finish from the plane is usually very good, reqiuring a minimum of scraping and sanding to complete, where a spindle-cut moulding may need quite a bit of work to clean it up. Another plus is that once a set of wooden planes is to hand, they can be put to work at a moment's notice. No need to grind up (and pay for) special spindle cutters, and set up the cutter-head. On the other hand, wooden planes do need a bit of understanding - they move with the seasons to some extent, so have to be fine-tuned and set each time they're used if that's infrequent. Wooden planes are much quieter than a spindle, though....