Your tool is pointing too high, starting at the outer edge you should be aiming to form an arc with the cutting edge that passes through the centre of the bowl.

And as been said adjust your bevel angle, such that you can maintain bevel contact through the whole sweep.

Spend some time doing this with the lathe stationary.

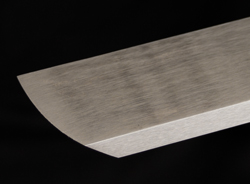

You may find that relieving the back of the bevel at a sharper angle gives more clearance on the curve without the heal of the bevel rubbing, just make sure you have sufficient working bevel to support the cut.

Whilst you are checking bevel contact with lathe stationary also investigate the effect of rotating the gouge slightly in your hands as the cut progresses, this, dependent upon how the gouge wings are ground can alter the angle of the bevel that is in contact.

One other point, although you have to be firm in the support of the tool, if it is sharp and cutting freely you don't have to grip it like a cold chisel, try putting your left hand under and on the outside of the front end of the gouge against the rest, sometimes referred to as a pinched grip, that way it is easier to traverse the tool towards the centre as you are pushing with you left hand in the direction of the required cut not just holding it down on the rest, the force of the cut will keep the tool on the rest.