PowerTool

Established Member

Blister":2zdf0jfo said:I am about to buy a lathe and am currently reading a turning book , so I am a virgin :wink:

thanks

That's ok,I'll try to be gentle.. :wink: :lol:

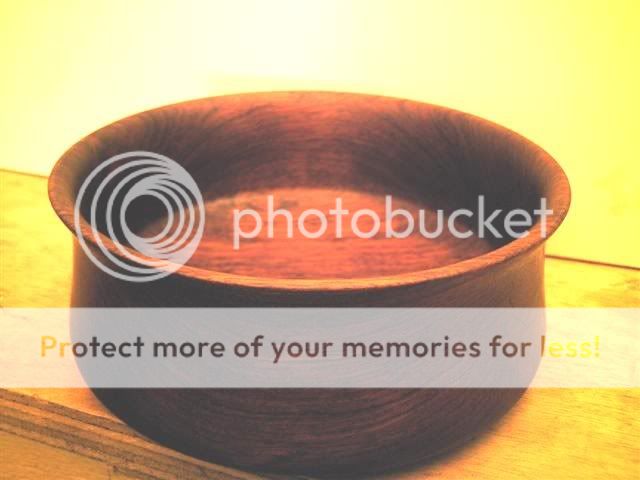

Here's the chuck :-

Dovetail jaws fit into approx.70mm recess

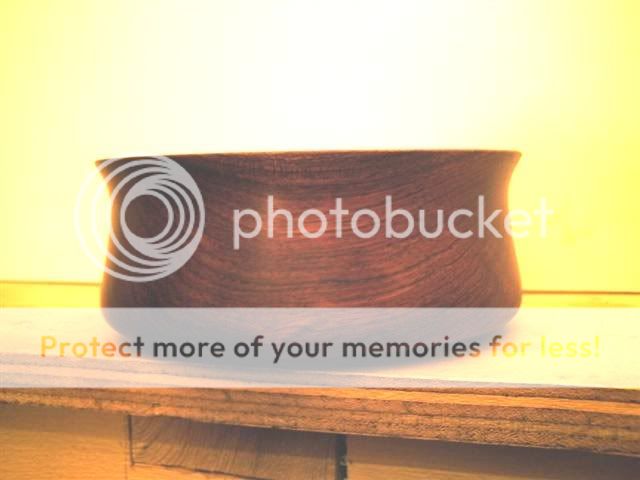

First couple of bases I did were like this

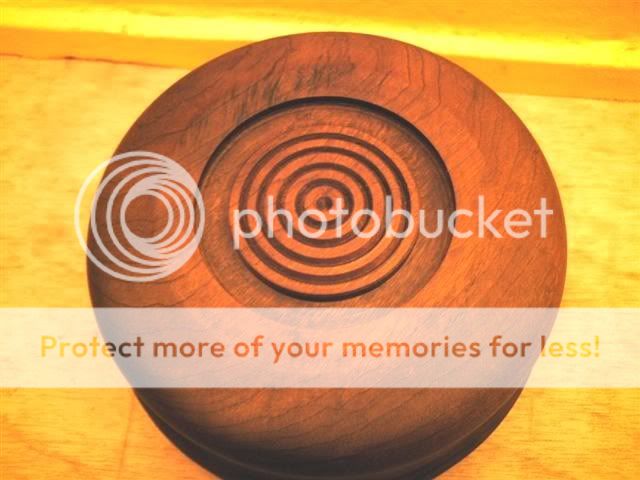

But now tend to leave a bit of decoration on them,like this

As for the thickness,blanks are often 50mm/2" thick to start with,and I actually like the chunky look (don't like skinny women either :wink: ) - so chucking recess is about 6mm,bases vary from 10-15mm,wall thickness about 6mm (now you've prompted me to measure them - just make them "by eye") ; the base thickness variation is depending on if the bowl is flat-bottomed or curved.

So this leaves about 30mm-ish depth of bowl from a 50mm blank.

Andrew