A

Anonymous

Guest

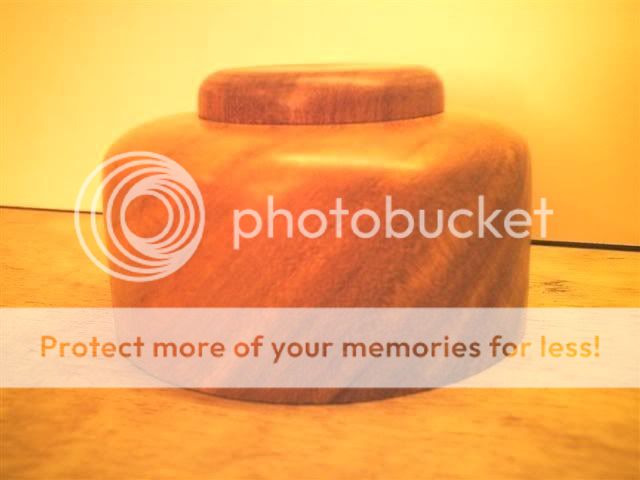

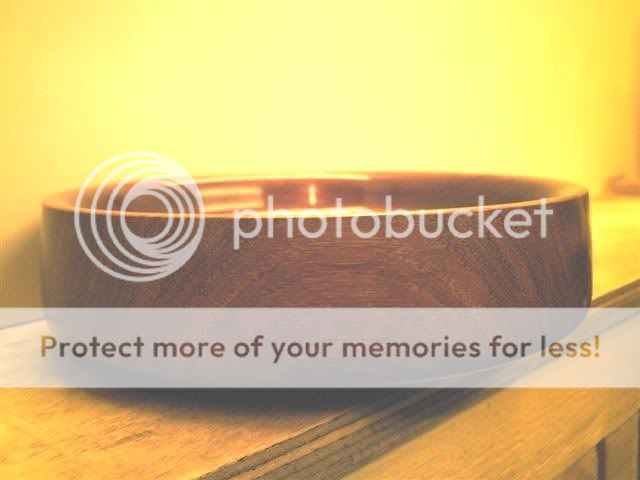

Andrew... good finish on the midweek bowl!

Just a suggestion... where compound curves meet have you thought of adding a small 'v' groove to mark the transition? One or two simple lines burned in with fine wire can also emphasise a feature curvy bit...

It's good to see that Chas is finally getting some competition :lol: :lol: :deer

Just a suggestion... where compound curves meet have you thought of adding a small 'v' groove to mark the transition? One or two simple lines burned in with fine wire can also emphasise a feature curvy bit...

It's good to see that Chas is finally getting some competition :lol: :lol: :deer