hi, Wallace how did you date the lathe? I have one machine no rs585 test no 18559 which looks older than yours. the top of the headstock is curved and the name is cast under the top window, the only other difference I can see is the top pulley which has no grub screws. I have had every nut & bolt to bits on this lathe and also fitted an indexing arrangement and painted it wadkin green. I don't think I am too far away from you in Bd Castle ? keep up the good work regards Stan

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

wadkin RS lathe restoration

- Thread starter wallace

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

merlin

Established Member

Hello Stan,

I restored mine last year - it is an RS 10, the machine number is RS 579 and the test number is 18327.

I phoned up Daltons and was told that it was manufactured in 1942, yours was probably in the factory at the same time !

Yours sounds like the same with the window and the casting.

Cheers, Merlin

I restored mine last year - it is an RS 10, the machine number is RS 579 and the test number is 18327.

I phoned up Daltons and was told that it was manufactured in 1942, yours was probably in the factory at the same time !

Yours sounds like the same with the window and the casting.

Cheers, Merlin

Thanks for that Merlin, we have a lot of Wadkin machines but I try to avoid Dalton's as I have never found them very helpful. Back to the lathe, I actually joined the bed of another RS lathe together, we can now turn 10' - 7" by 17" dia. The spare head stock we have fixed a 6' - 9" dia. face plate controlled by an inverter drive. If I can persuade my son to take some photographs and upload them for me you will see what I have done, I am no good at modern technology. regards Stan

wallace

Established Member

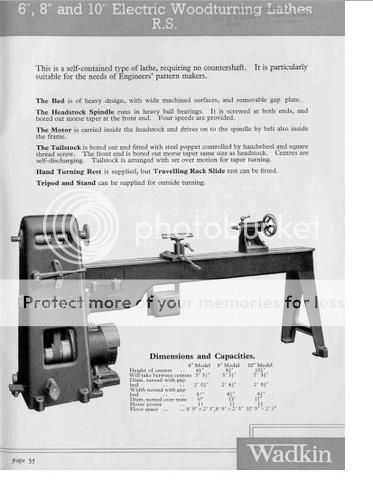

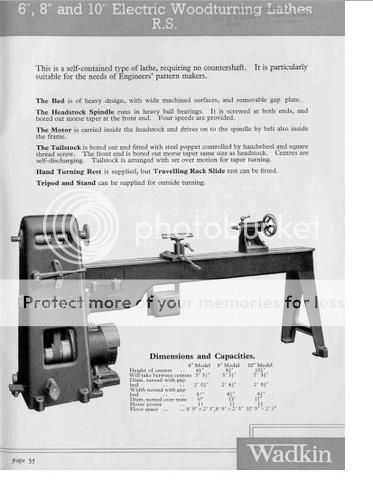

Hi Stan this is the earliest version of the RS I have come across. It does not have a brake or the pin that locks the spindle on the outboard side. To lock the spindle you have to do it through the window. The tailstock is different in a few ways, the motor is different as well.

A friend has a catalogue dating from 1936 and it is identical to my lathe.

Your lathe is quite early because of the window, depending on which type of machine tag you have you might be able to date yours. If it is a tin tag then you cant get the date, if its a brass cast tag then it has the year on it. If you look at this PK tag the machine serial number, the first 2 digits represent the year of manufacture, so 1955.

So two lathes joined, have you turned anything to its capacity?

A friend has a catalogue dating from 1936 and it is identical to my lathe.

Your lathe is quite early because of the window, depending on which type of machine tag you have you might be able to date yours. If it is a tin tag then you cant get the date, if its a brass cast tag then it has the year on it. If you look at this PK tag the machine serial number, the first 2 digits represent the year of manufacture, so 1955.

So two lathes joined, have you turned anything to its capacity?

wallace

Established Member

wallace

Established Member

I some how managed to drop the handle of the banjo and it broke (homer) To fix it I drilled and tapped each bit and then welded

This time I used my new face shield my wife bought me 12 months ago, so no burnt brow. I'm not the best welder but it ground down pretty well with just a couple of pin holes.

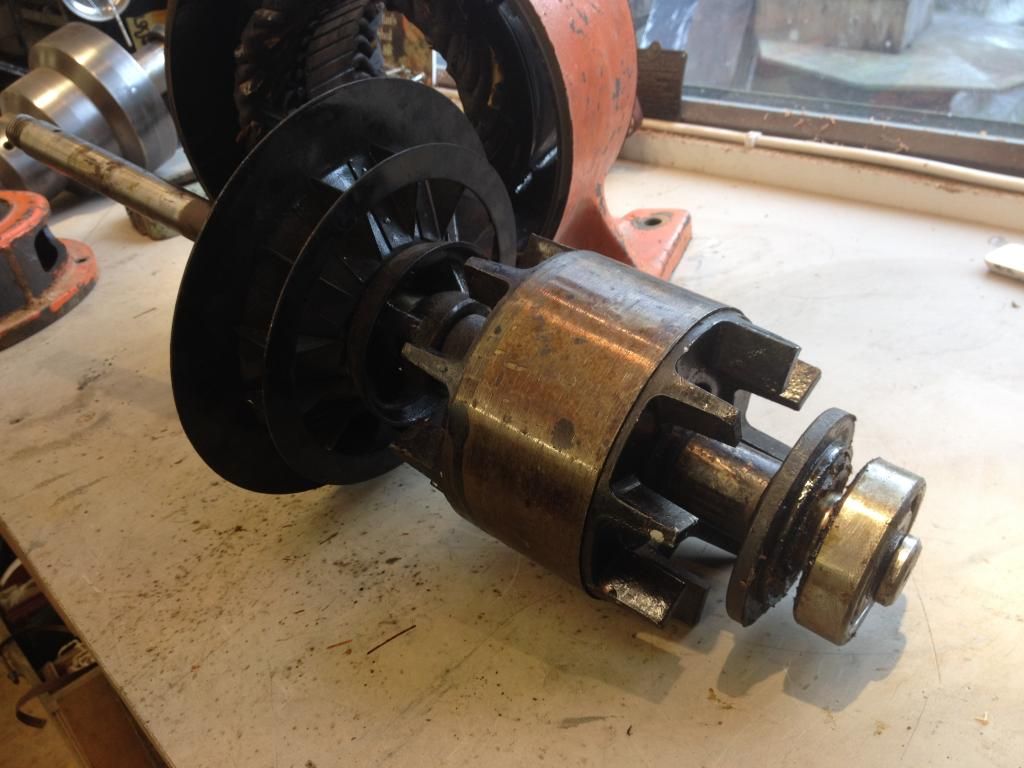

I thought I'd strip the motor, I tested it before and it is good.

The pulley support had not been taken off before and it was full of pretty clean grease.

I tried a puller on the pulleys and it moved easily and then stopped when it got to a collar on the shaft, it wouldn't budge so I looked closer.

The collar is pinned through the shaft.

This time I used my new face shield my wife bought me 12 months ago, so no burnt brow. I'm not the best welder but it ground down pretty well with just a couple of pin holes.

I thought I'd strip the motor, I tested it before and it is good.

The pulley support had not been taken off before and it was full of pretty clean grease.

I tried a puller on the pulleys and it moved easily and then stopped when it got to a collar on the shaft, it wouldn't budge so I looked closer.

The collar is pinned through the shaft.

I somehow managed to miss this. Now found and enjoying it.

Mick

Mick

Reassuring to know that someone who does beautiful restorations is nearly as cr*p at welding as I am!

dickm":2n120bi0 said:Reassuring to know that someone who does beautiful restorations is nearly as cr*p at welding as I am!

A welder told me you don't need to be good with the torch, you need to be good with the grinder :lol:

wallace

Established Member

I just point and press and hope for the best :lol:

wallace

Established Member

wallace

Established Member

I have been spending a lot of time doing the prep on the castings before giving a coat of zinc primer.

The main headstock is taking a lot of work, it has a lot of dings and the casting are pretty rough

This is how I do the tags,

After cleaning with a brass wire brush, I sanded and then polished

I then spray with a black paint from a rattle can. It takes a few coats to fill the background

The main headstock is taking a lot of work, it has a lot of dings and the casting are pretty rough

This is how I do the tags,

After cleaning with a brass wire brush, I sanded and then polished

I then spray with a black paint from a rattle can. It takes a few coats to fill the background

VanTheMainMan

Member

Those tags came out looking very good!!!!

wallace

Established Member

wallace

Established Member

wallace":1ziw71i1 said:

Are these easy to wire in? I have a 3ph motor on my drill which I need to get one of these for.

wallace

Established Member

They are really easy just Live Neutral earth in and three wires and earth out. Plug it in and it configures itself to the motor

wallace

Established Member

I have been doing a lot of painting in the past few days, because I use enamel you can build the coats up quite quickly. By the time I've finished spraying I can go back to the beginning to give another coat. When done I left everything for two days and then went over again.

The bed was is really nice condition with nearly all of its original filler intact. This is the first wadkin I've found which was originally black

It has the number 115 stamped at the end of the bed which corresponds to the machine number on the tag

The bed was is really nice condition with nearly all of its original filler intact. This is the first wadkin I've found which was originally black

It has the number 115 stamped at the end of the bed which corresponds to the machine number on the tag

Similar threads

- Replies

- 2

- Views

- 1K