wallace

Established Member

Time to restore a big boy lathe. This is the one Berncarpenter had for sale, and I couldn't resist. He made a huge effort to make sure it was well and truly secured to the pallet by bolts, screws, staples and rope. I am very thankfull because pallet couriers seem to getting worse. Everything arrived safe and I spent a good hour freeing everything from the pallet

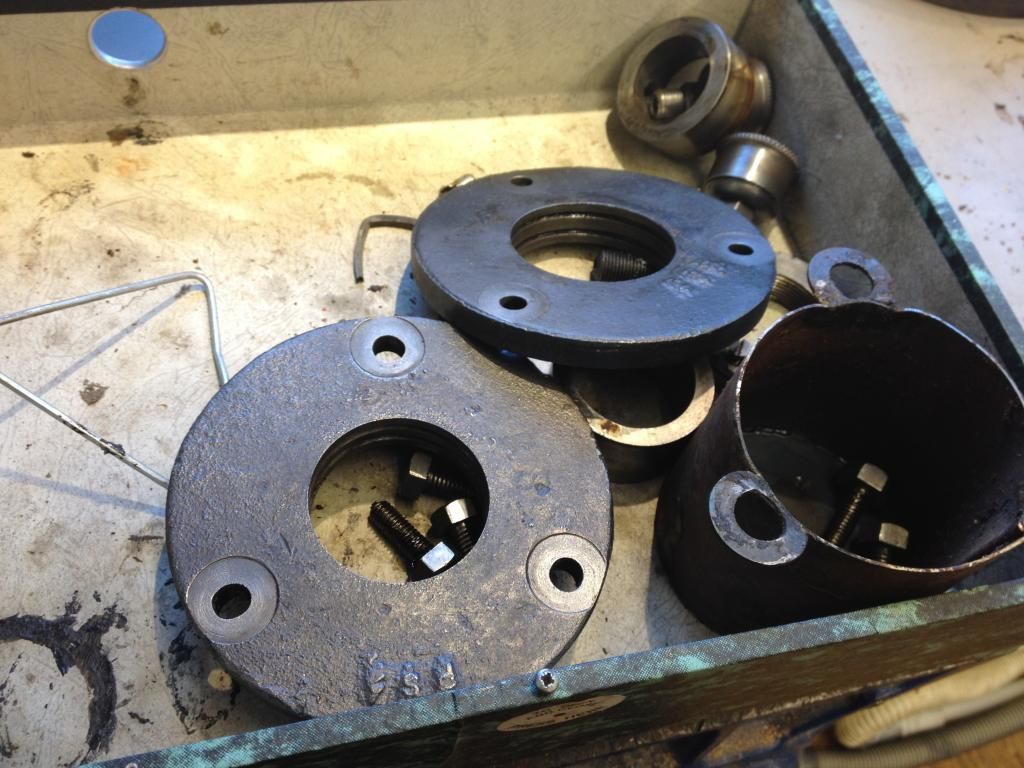

Then I started to break the machine down to its components, I have a good selection of pullers from car boots or these cheap hong kong ones. Really a must when messing with old iron.

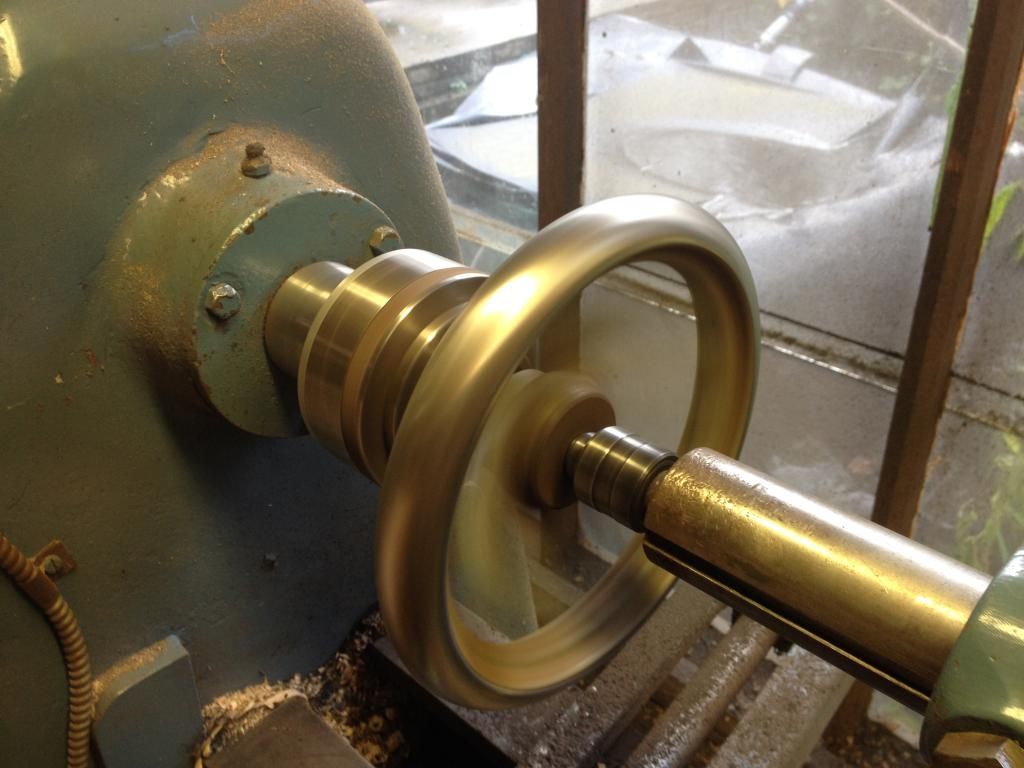

When I took the chuck off I was amazed at the quality of the threads, either the chuck has not been taken off much in the last 80 years or it has had a new shaft at some point.

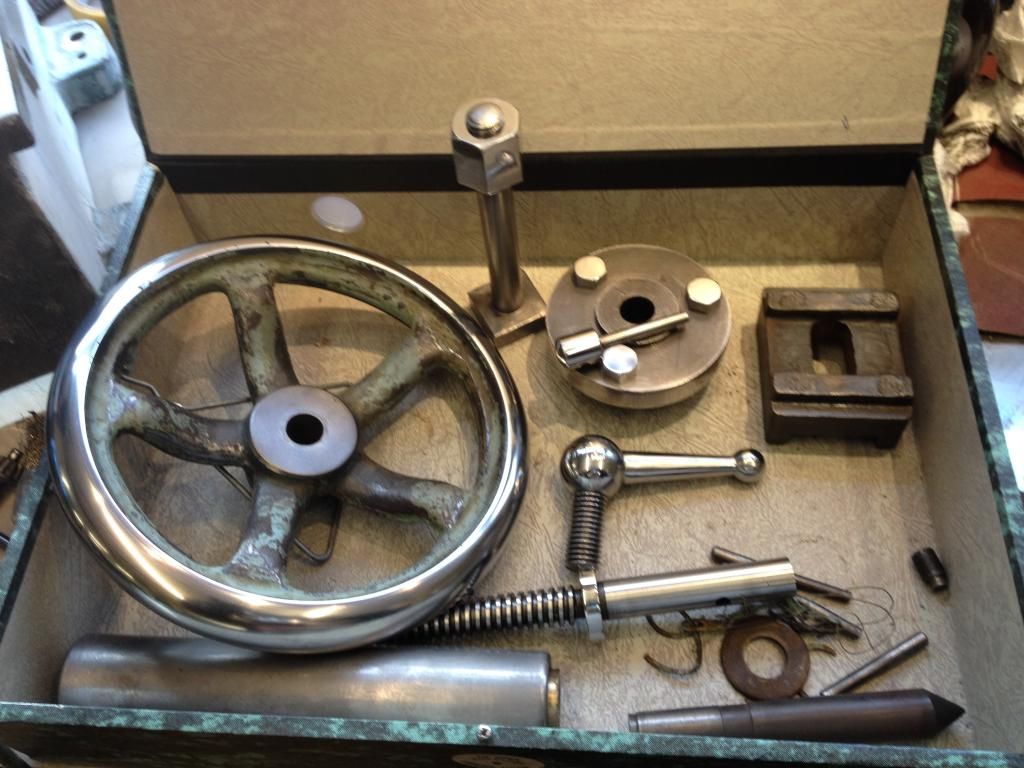

It all came apart pretty easy

The motors quite a lump for 1.5hp

Then I started to break the machine down to its components, I have a good selection of pullers from car boots or these cheap hong kong ones. Really a must when messing with old iron.

When I took the chuck off I was amazed at the quality of the threads, either the chuck has not been taken off much in the last 80 years or it has had a new shaft at some point.

It all came apart pretty easy

The motors quite a lump for 1.5hp