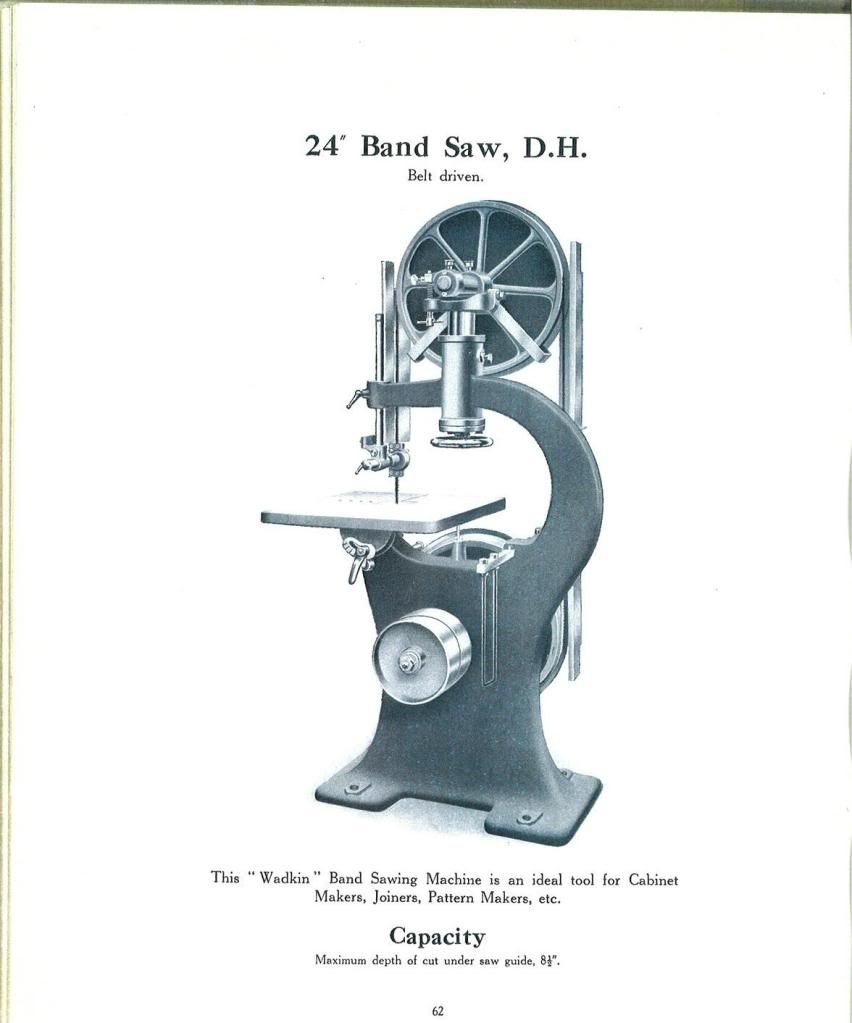

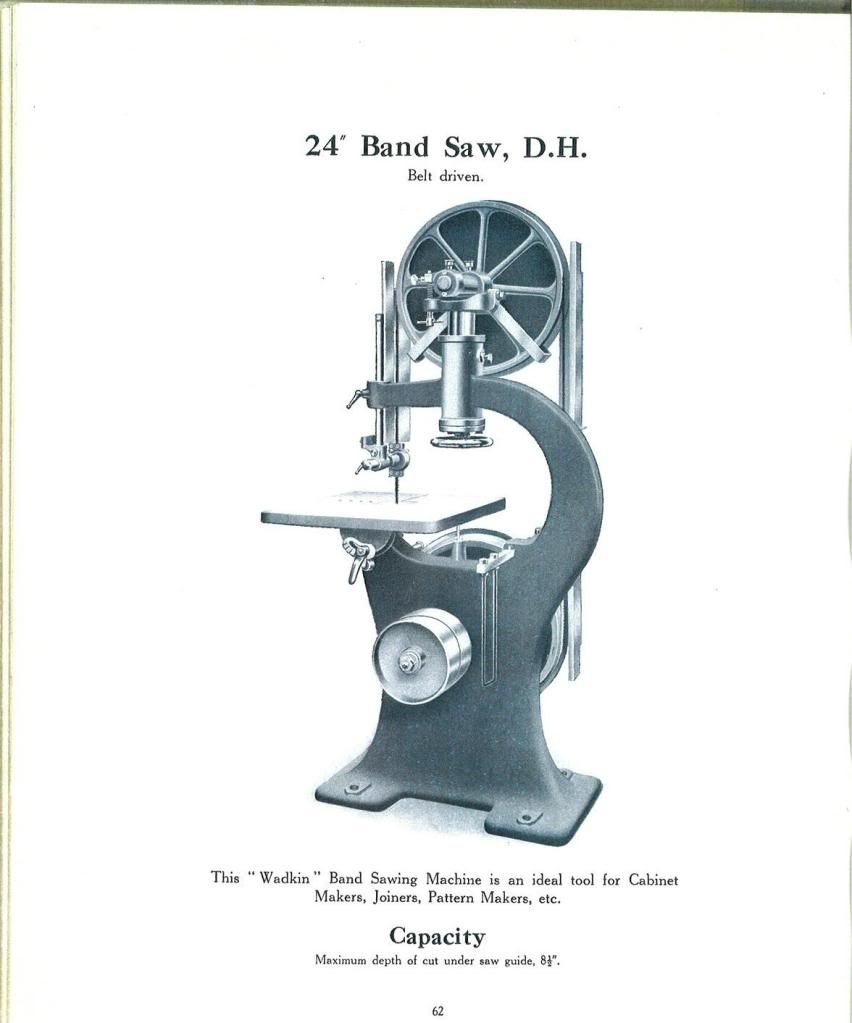

The Wadkin DR is the last of the old Wadkin C frame designs for the early 20s when line belt machines were offered. The earliest of the D family of band saws was the DJ then DH line belt saws for the early 20s.

One of these saws was save in England by a bench maker a few years ago. you may know this chap :mrgreen:

Then there was the first motor drive saw the Wadkin &Co DNA

the Wadkin propellor logo is a motor rotor on later wadkin tags of the DH and tell me it was made some were around 1928 . This saw is a Wadkin & CO the propeller logo was carried for a few years after Wadkin went Ltd in 1936 on motors but BTH later took over.

Matty Melbourne found this in his collection

re the logo I don't know, but it may not be a propeller at all... possibly a pump symbol??

Could it be a Symbol for an electric motor ?

1928 Wadkin were one of the first companies to integrate Electric motors with their woodworking equipment in England.

A little more on this bandsaw . I believe that the DH/DNA(A meaning it came from Green lane works with an electric AC motor Drive ) is a 28" saw With spoked wheels . They may even be cast aluminium pulleys. More information is need on this saw for documenting. What is interesting to note is how round the C fame is to the older DH. The upper pulley tension arrangement is centered under the wheel/pulley as well. The early DR boxed out the frame and made the saw larger in 30" and 36" there was also a hand brake add.

here is a DNA 128" with a "Test Number" of 6812 (28" saw) with a squared off C frame but only the Wadkin & Co cast in the upper hub guard (Older DN models had it cast in the frame) . This looks to be its next design change(1928). Note that the tension design of the upper pulley is retained from the old DH.

Some time in the 40s I believe all these old designs were reworked and the D range was changed again . This time they change the tension design and added the hand brake.This is my Wadkin DR with all the new features like Motor guard. back guard closing in the upper pulley that is no long rounded on top. Larger motors and drive systems are added and the blade guilds are upgraded. the DR was the last of the cast C frame saws wadkin made. The Bursgreen BZB was to take off from here and it would not to long before Wadkin went to a steel frame saw. Wadkin was late to do this as others had 10 years earlier .

Bursgreen was originally set-up in about 1932 by a Mr Burroughs and a Mr. Green (hence "Bursgreen") with the stated intention of manufacturing newer, lighter woodworking machinery designs based on the lightweight machines then appearing in the USA. The principle was to build a fabricated base with cast-iron tops or "thin skin" cast iron framed machine that could be built more or less "on-demand" as opposed to the traditional cast and machine a batch then common to the industry. To that end Bursgreen were certainly successful. By 1947 Burroughs Green had become part of John Sagar & Sons (Halifax, England - established 1875) one if the largest woodworking manufacturing companies in this country - and were selling through a new company, Sagar (Developments) Ltd.

you can see all in this 1955 Sagar machine catalog

http://vintagemachinery.org/pubs/3015/4606.pdf

By 1954 Sagar and Bursgreen were trading as Sagar Bursgreen Ltd. and the two factories had been “hived-off” as Bursgreen (Durham) Ltd and Bursgreen (Colne) Ltd. Sagar in turn sold-out to Wadkin in 1956 and by 1959 all production at Sagar's Canal Works in Halifax had ceased with most of the production being transferred to the more modern Bursgreen works at Fence Houses, Houghton-le-Spring in Co. Durham and Trawden, near Colne in Lancashire. Wadkin Bursgreen took over some of the Sagar designs, such as the UO/S 18 x 9in combined planer/thicknesser and the UO thickness planers (which re-used a lot of components from the heavier Sagar GES 24 x 9in combined planer/thicknesser) but the Sagar products were quietly dropped after the take-over as they directly paralleled products from Wadkin’s heavyweight range (these firms were, after all, rivals). There is some indication that in the early period Wadkin intended to keep Bursgreen as a separate entity – production of one or two machines such as the Wadkin LM borer were transferred from Wadkin’s factory at Green Lane in Leicester to Bursgreen and rebranded “Bursgreen”, but by 1958 the brand “Wadkin Bursgreen” had appeared and continued to be used on the “lightweight” range for the next 30 or so years. Bursgreen in fact designed and built some heavy mainstream Wadkin products in addition to the lighter fabricated products, including the PP dimension saw (the successor to the PK and similarly all cast iron, including the base and even heavier), the all cast-iron BZB bandsaw (in 30in and 24"wheel sizes and big brother of my Sagar Bursgreen MZF), the BAO/S combined planer/thicknesser (up to 24 x 9in), the UX and UR series of pin routers and all of Wadkin’s CNC router production until the closure of Trawden in the 1990s. Some of the lower volume smaller machines such as the LQ recessor were transferred to them as well. However, after 1960 Wadkin never sold their machines as anything other than Wadkin or Wadkin Bursgreen.

jack English machines