Woody Woodpecker

New member

- Joined

- 4 Dec 2007

- Messages

- 3

- Reaction score

- 0

Hello.

I am brand spanking new here ... in more ways than one, in fact, being relatively new to the UK and also being an UNprofessional woodworker/carpenter.

I am about to undertake what is a pretty mammoth task ... well, for me anyway and need a very simple pointer in the direction of the best wood glue in the UK for my needs..

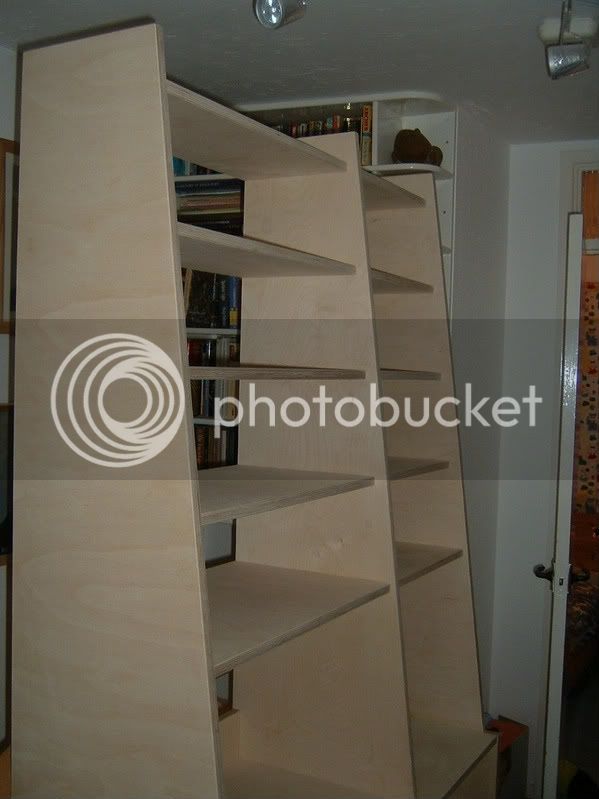

I have already bought 11 sheets of 18mm Birch Ply and had it cut to the sizes required for my project, which is to make 17 slanted racks for my recording studio.

Eack rack will basically be a box, without a front and back as such.

I plan to dowel join the top and bottom pieces on the inside edge of the two sides, with 2 or 3 x 100mm braces at the back as the only means of additional support.

Without going into any more unecessary details (unless required), could somebody please tell me what is the best wood glue to use for my project?

I have no idea where to start and have searched this forum (and Google) endlessly for a basic idea as to what is "the good stuff", to no avail, with various salesmen at my local stores basically pointing me in the direction of the shelves full of different brands and I need a bit of experienced advice if possible.

Many thanks for any help and answers.

Woody.

I am brand spanking new here ... in more ways than one, in fact, being relatively new to the UK and also being an UNprofessional woodworker/carpenter.

I am about to undertake what is a pretty mammoth task ... well, for me anyway and need a very simple pointer in the direction of the best wood glue in the UK for my needs..

I have already bought 11 sheets of 18mm Birch Ply and had it cut to the sizes required for my project, which is to make 17 slanted racks for my recording studio.

Eack rack will basically be a box, without a front and back as such.

I plan to dowel join the top and bottom pieces on the inside edge of the two sides, with 2 or 3 x 100mm braces at the back as the only means of additional support.

Without going into any more unecessary details (unless required), could somebody please tell me what is the best wood glue to use for my project?

I have no idea where to start and have searched this forum (and Google) endlessly for a basic idea as to what is "the good stuff", to no avail, with various salesmen at my local stores basically pointing me in the direction of the shelves full of different brands and I need a bit of experienced advice if possible.

Many thanks for any help and answers.

Woody.