chingerspy

Established Member

Hi all,

Well it's about time I started sharing and the upcoming garage project is as good a place as any.

Basically we have a load of old wood in the garage which I've gathered up and hope to use in these garage projects. There are bits of old beds, furniture, contiboard, etc...

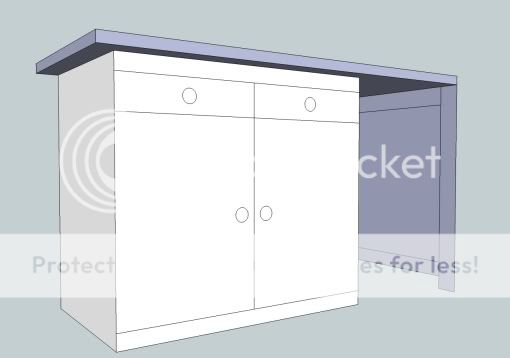

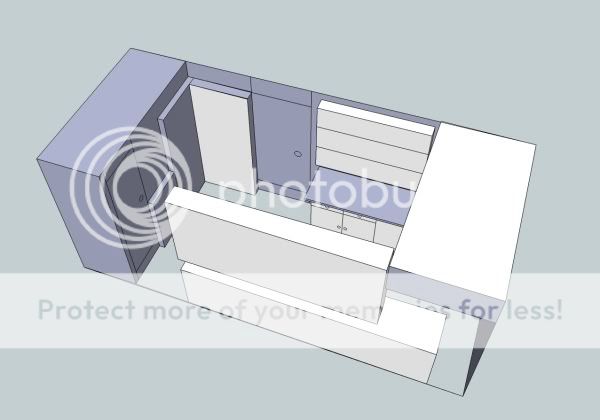

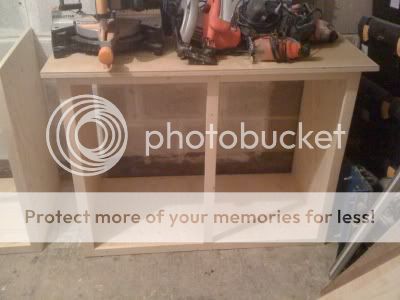

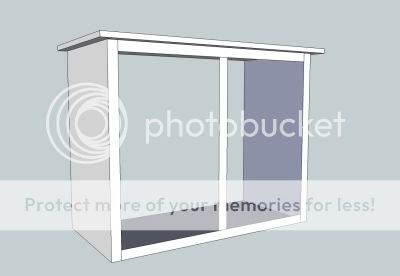

I've been thinking hard how to go about making the bits. I think I'm settled on using pocket hole joints after deliberating about traditional M/T or biscuits or dados. After watching Kreg stuff on Youtube I'm going to pick up a Kreg 3 or 4 from Axi High Wycome on Friday. I like faceframes and I think I will be able to make a good job of the furniture with the Kreg. Does anyone else use them here? I don't read a lot about them on this forum. So pine faceframes and plywood sides. Plan is to make two cabinets that the worktop will go on. Then some shelving above to take some more storage that's got to stay in the garage for the time being. Should end up with a 2'x5' worksurface with storage under and over it.

Anyway... here goes!

First I found all the suitable framing bits from the old pine. There was a lot of 45x20mm lengths so I chopped all the dodgy ends off and came up with some nice useable bits for free The Evolution Rage3 for £100 is earning it's money!

The Evolution Rage3 for £100 is earning it's money!

Here's the small pile I ended up with looks like I might have to buy some planks if I can't find any more hiding in the woodbin. I made a note of all the sizes in pencil on each length after chopping them. I've now written it all down on a pad and will hopefully be able to create some sort of cutting list to make my frames or at least some of them:

I'm also getting into the habit of cleaning up shop afterwards, here's the current shop vac:

And I'm also reclaiming sawdust from the reclaimed timber! It's going to come in handy for all the filling I will probably end up doing knowing me This old Jelly Belly jar is filling up quickly:

This old Jelly Belly jar is filling up quickly:

Well this is the start of the WIP. I have Friday through Monday off work so hopefully will get the jig and get used to it quickly to progress on the build.

Well it's about time I started sharing and the upcoming garage project is as good a place as any.

Basically we have a load of old wood in the garage which I've gathered up and hope to use in these garage projects. There are bits of old beds, furniture, contiboard, etc...

I've been thinking hard how to go about making the bits. I think I'm settled on using pocket hole joints after deliberating about traditional M/T or biscuits or dados. After watching Kreg stuff on Youtube I'm going to pick up a Kreg 3 or 4 from Axi High Wycome on Friday. I like faceframes and I think I will be able to make a good job of the furniture with the Kreg. Does anyone else use them here? I don't read a lot about them on this forum. So pine faceframes and plywood sides. Plan is to make two cabinets that the worktop will go on. Then some shelving above to take some more storage that's got to stay in the garage for the time being. Should end up with a 2'x5' worksurface with storage under and over it.

Anyway... here goes!

First I found all the suitable framing bits from the old pine. There was a lot of 45x20mm lengths so I chopped all the dodgy ends off and came up with some nice useable bits for free

Here's the small pile I ended up with looks like I might have to buy some planks if I can't find any more hiding in the woodbin. I made a note of all the sizes in pencil on each length after chopping them. I've now written it all down on a pad and will hopefully be able to create some sort of cutting list to make my frames or at least some of them:

I'm also getting into the habit of cleaning up shop afterwards, here's the current shop vac:

And I'm also reclaiming sawdust from the reclaimed timber! It's going to come in handy for all the filling I will probably end up doing knowing me

Well this is the start of the WIP. I have Friday through Monday off work so hopefully will get the jig and get used to it quickly to progress on the build.