Wildman":17h7j08q said:

jasonB":17h7j08q said:

A woodruff cutter won't work as there is no relief and the cutter won't follow the helix angle. Same as trying to screwcut a square thread on an engineering lathe without grinding clearance on the tool.

And 7/8x16 taps are available from about £12 not £30-70.

J

I said woodruff type (not form) and a small dia cutter will create its own threadform like a hob it is a common way to mill threads. The price I quoted was the price I had seen for Whitworth form threads UNF are much cheaper. Anyway enough of trying to be helpful after 50 years in Engineering I obviously learnt nothing apart from how to create argument. I'll stick to asking stupid questions rather than trying to help anyone. Obviously thats all I'm fit for practically every post I have made over the past few days has been picked on really not what I was looking for in a forum.

I was only pointing out that if the purchaser wanted to do smaller threads then taps can be had for less and they were whitworth form 55deg that I quoted, 7/8" x 16 is not available in UNF.

You don't seem to have grasped how this jig works because you said

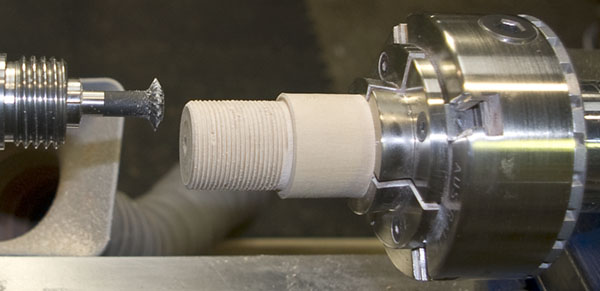

"if you are thinking of threading large diameters or long pieces then not of much use" because you thought it only cut the male thread, if you look closely at the picture on the e-bay advert & Robbo's B&K link you will see that the cutter is of the "woodruff type" you talk about so will indeed act much like a thread mill and will cut internal threads from 1" upwards. Again I only raised these points to correct the wrong information you were giving to the OP and you did say "that you may have got it wrong again" , think you did :wink:

J