bogmonster

Established Member

A bit more shed time today - only got half what I wanted done but here is one item some may find interesting:

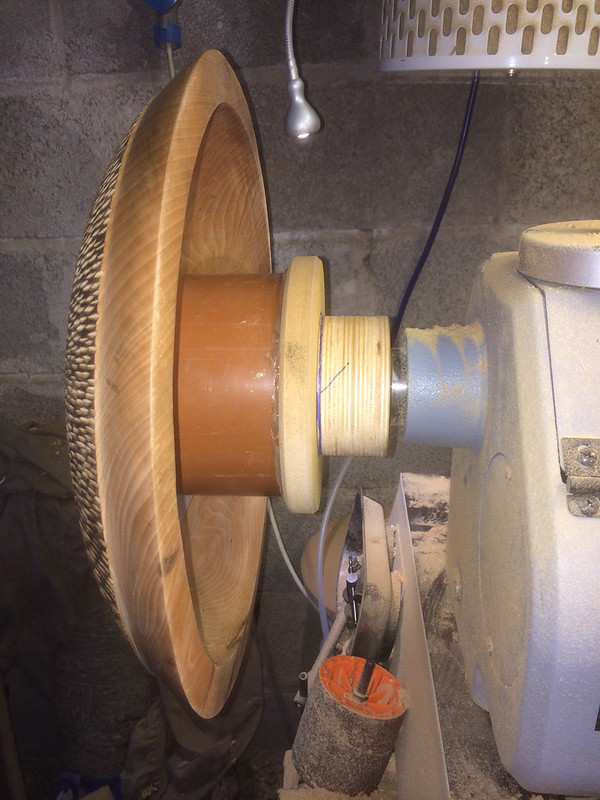

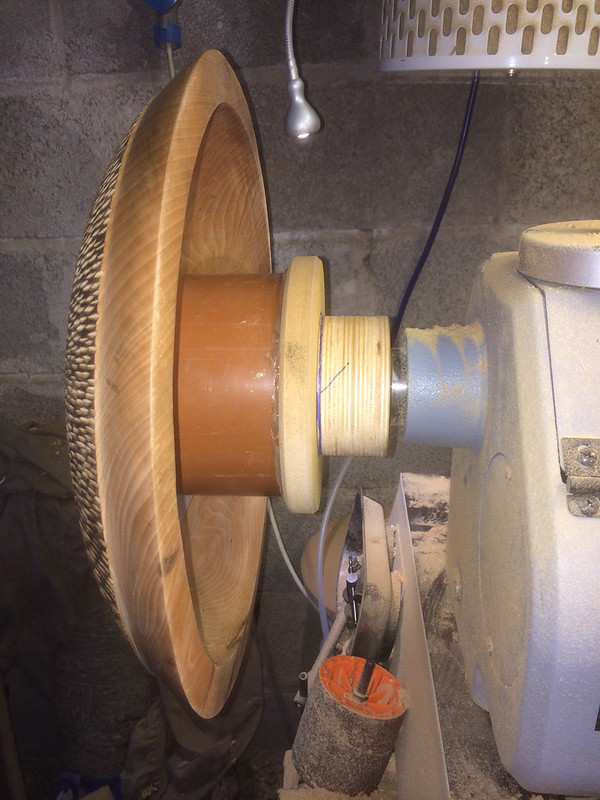

The vacuum chuck - not the bowl

The bowl is about 18" and has been kicking around for a while to be finished. Ran into difficulty when it shrank a bit and I could no longer fit is on jaws to finish sanding and apply finish. I only used to have a 4" vacuum chuck and a lathe that started fiercely at 350 RPM which meant no way to mount mount on the vacuum chuck and widen the rebate.

The new vacuum chuck is 6" which means way more holding power and coupled with a soft start variable speed lathe I can safely finish this bowl. I am going to make a new 4" chuck as well. The construction is kind of obvious. Soil pipe for the chuck wall. MDF for the base. I used a M33 Tap (new toy) for the spindle mount. The hose is beer line connected up with John Guest fittings (these are the mutts nuts). The bearing is push fit in and it is the weak link as it is a low quality affair - should have bought high quality double sealed.

EDIT: Forgot to mention, I use a loose gasket between the wood and chuck as it is easy to replace and very simple. I use closed cell laminate floor underlay. Had some left over.

The holding force is amazing. Mrs BM was not impressed with 6" though. I think she is holding out for 8.

Other stuff I made was a couple of sanding discs using the same M33 tap and painted up my steady. Also got to try my new DIY tool rests which worker a treat but that is a different thread.

BM

The vacuum chuck - not the bowl

The bowl is about 18" and has been kicking around for a while to be finished. Ran into difficulty when it shrank a bit and I could no longer fit is on jaws to finish sanding and apply finish. I only used to have a 4" vacuum chuck and a lathe that started fiercely at 350 RPM which meant no way to mount mount on the vacuum chuck and widen the rebate.

The new vacuum chuck is 6" which means way more holding power and coupled with a soft start variable speed lathe I can safely finish this bowl. I am going to make a new 4" chuck as well. The construction is kind of obvious. Soil pipe for the chuck wall. MDF for the base. I used a M33 Tap (new toy) for the spindle mount. The hose is beer line connected up with John Guest fittings (these are the mutts nuts). The bearing is push fit in and it is the weak link as it is a low quality affair - should have bought high quality double sealed.

EDIT: Forgot to mention, I use a loose gasket between the wood and chuck as it is easy to replace and very simple. I use closed cell laminate floor underlay. Had some left over.

The holding force is amazing. Mrs BM was not impressed with 6" though. I think she is holding out for 8.

Other stuff I made was a couple of sanding discs using the same M33 tap and painted up my steady. Also got to try my new DIY tool rests which worker a treat but that is a different thread.

BM