Mike 1 (Canada)....ah! Ok...I trust your description...though Richard did say he designed the side as the

Great Wave Off Kanagawa so I followed that lead and bookmatched the rear so that it was like a shark fin running through the water after the wave...

By bookmatching...I could get the grain in the wood to flow out from either side like a wake.

But I'll go with the dragon idea too....it certainly bites like one! :wink:

Mike 2 (Bedrock)....

Funny you should say that because when I was doing the second bolt this afternoon I thought to myself...ok...it's only a bolt but I bet someone asks......etc! :mrgreen:

So...I took some pictures...at some of the stages anyway.

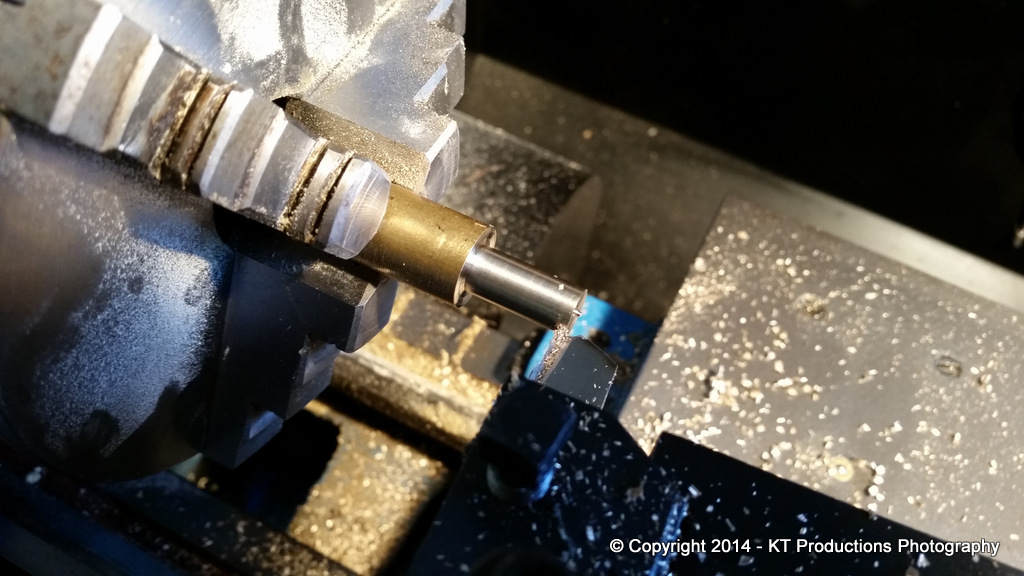

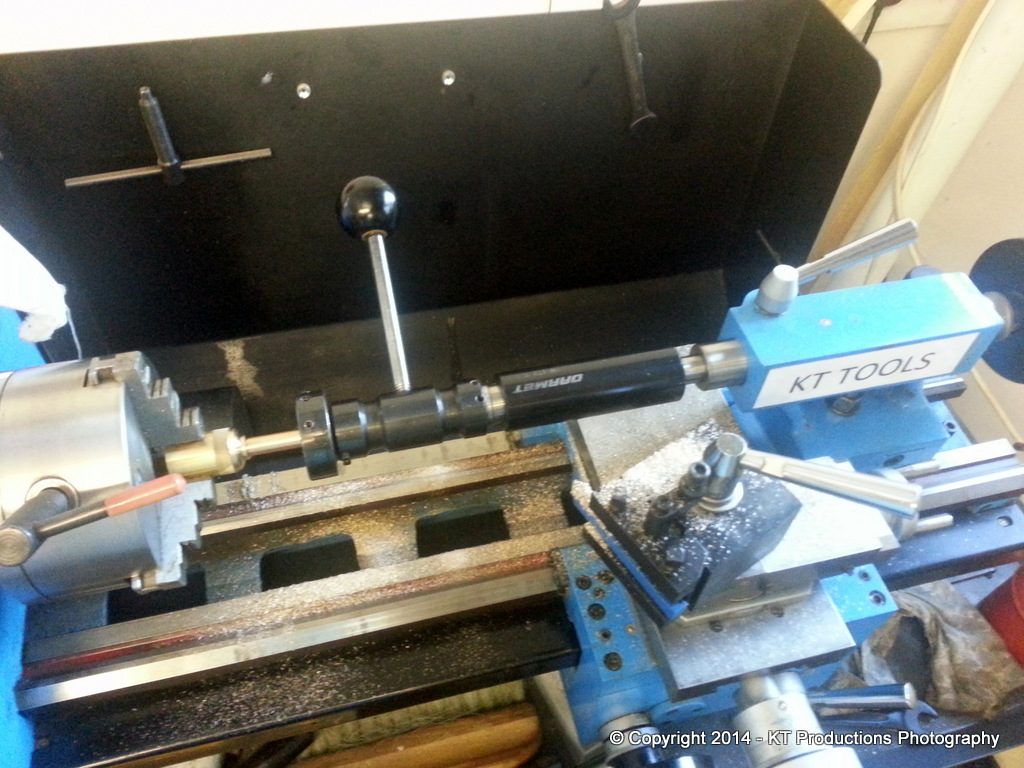

A round brass bar big enough to be slightly larger than the maximum size of the head was mounted in the chuck and then the diameter run down square...

When I got near the right diameter for the OD diameter of M5 thread I did just the end to test the caliper diameter...

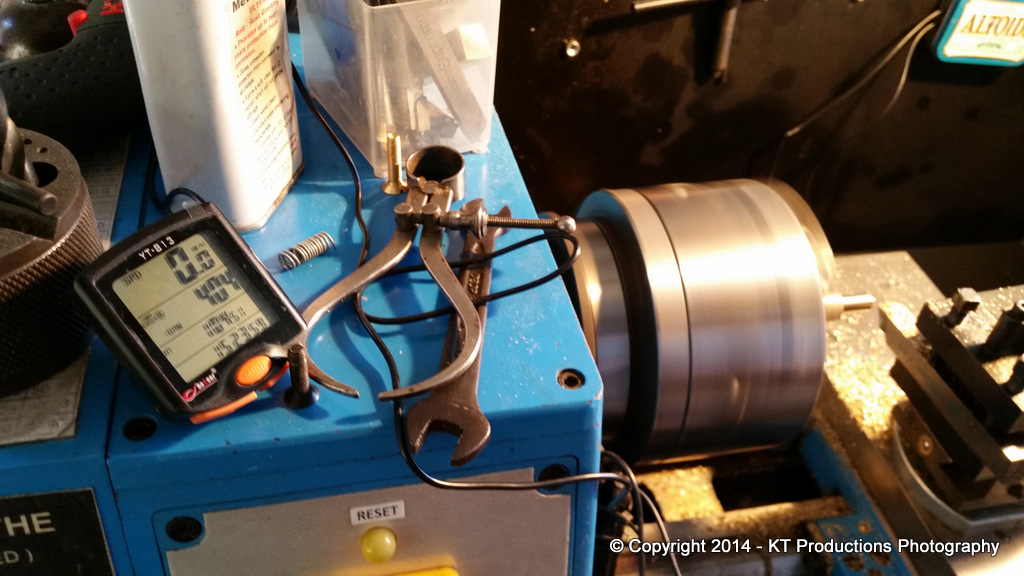

I don't have a tacho on my lathe so was going to buy one from Axminster but they are silly money and they're only Hall Effect switches and a meter so I bought one for a push bike for a fiver from China...

....and the indicator matched my laser tacho exactly! I was very pleased! 8)

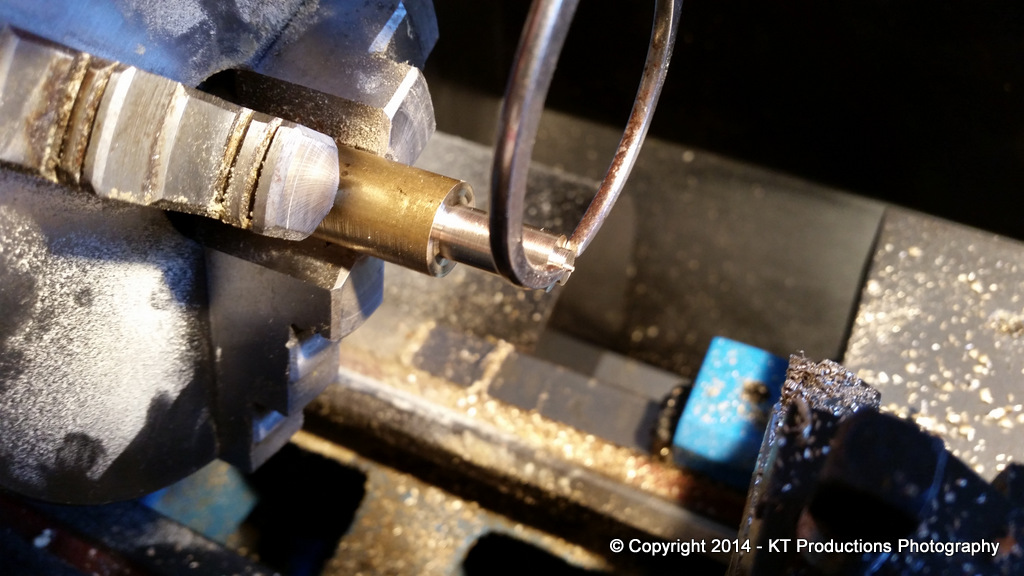

I then ran the diameter all the way back to the end of the screw part...

I then moved the cutter to give the correct angle for the countersink taper...and cut the thread with a hand die stock...

Leaving a blank shoulder as you suggest.

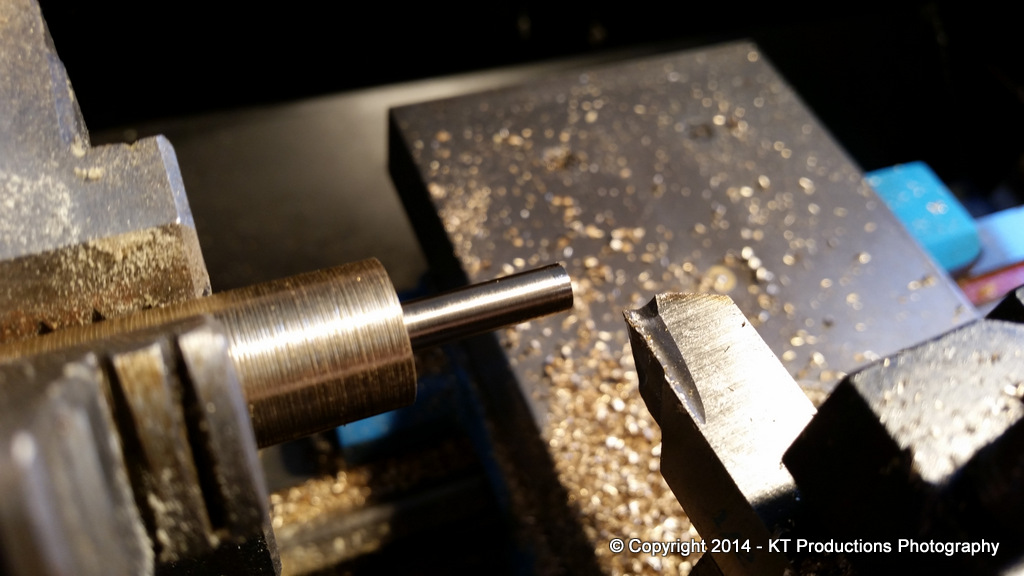

The machine screw can then be cut off using a parting tool just proud of where the head will be to give me the opportunity to cut it down to the exact size by turning it around.

When mounting the thread I wound some wire around the threads and set it in the chuck so as not to damage the threads...as recommended by AndyT in his most excellent tip!

I then cut the slot by eyeballing the centre and using a junior hacksaw for a thin slot...finishing with a flat needle file and polishing on the lathe with abrasives.

I hope this helps...

Jimi