I'm planning on building an extra large bench for the new workshop to go along side my 5x2' old bench.

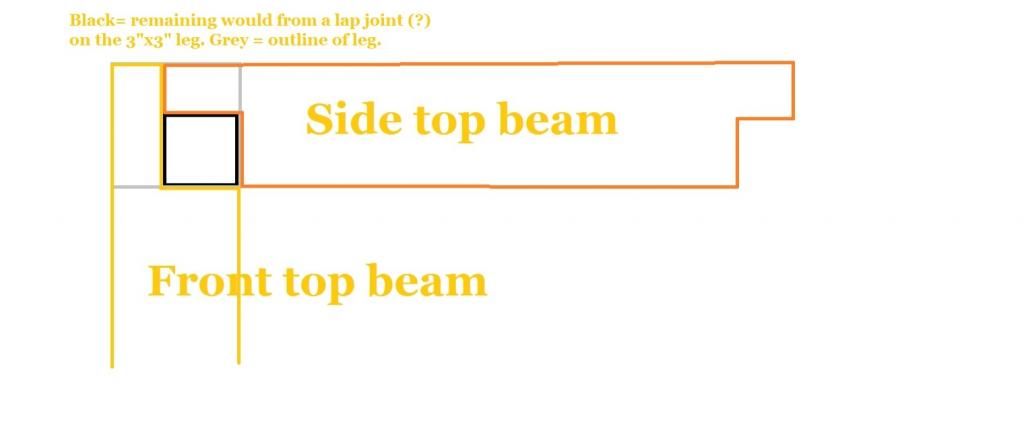

I'm most likely going to build a 6x2.5'. I'm planning on using old 3x3" fence posts for the legs, 4x2" for the bracing around the top for the top to screw onto, then I have various bits of 3x2 and 2x2 timber for additional bracing.

I'll be using either 7x2 or 8x3 for the work top, depending what I can get cheapest in best condition (reclaimed timber)

Main question I have is will I need 4 or 6 legs having a pair in the middle for extra support?

I'm a complete newbie when it comes to wood work, I'll be copying the joints on my old bench that my dad built to try and make it as neat as possible.

But basically all timber I'll be using is reclaimed, my old fence posts, a tamper beam from my concrete base, a pallet from a OSB sheet delivery and lots donated by my dads old work and also a full length of timber a neighbour dumped in my tree line..... thanks!

Any pics of corner joints for the legs or mid way joints for the extra supporting joints will be very helpful as would any tips on cutting them.

Thanks in advance.

I'm most likely going to build a 6x2.5'. I'm planning on using old 3x3" fence posts for the legs, 4x2" for the bracing around the top for the top to screw onto, then I have various bits of 3x2 and 2x2 timber for additional bracing.

I'll be using either 7x2 or 8x3 for the work top, depending what I can get cheapest in best condition (reclaimed timber)

Main question I have is will I need 4 or 6 legs having a pair in the middle for extra support?

I'm a complete newbie when it comes to wood work, I'll be copying the joints on my old bench that my dad built to try and make it as neat as possible.

But basically all timber I'll be using is reclaimed, my old fence posts, a tamper beam from my concrete base, a pallet from a OSB sheet delivery and lots donated by my dads old work and also a full length of timber a neighbour dumped in my tree line..... thanks!

Any pics of corner joints for the legs or mid way joints for the extra supporting joints will be very helpful as would any tips on cutting them.

Thanks in advance.