Have a look at "The English Woodworker" and have a look at the holdfasts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The bench build WIP. First plane! Pg4.

- Thread starter PAUL_TDI

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

On the attached photo, you can see a couple of bench-dogs (original Workmate, no less) holding a board upright; the clear wood strip at the back is there to work as a stop for planing that board, and is in turn propped against a couple more bench-dogs located behind it. All these bench-dogs are inserted in dog-holes. Now you can see what the dog-holes are used for - and needed :wink:PAUL_TDI":39sib6y0 said:Thanks for the link, that certainly looks like a fairly basic sturdy build.

Thankfully my over bench already has a wood work vice fitted, I'm planning on getting an engineering vice for this one, My dad has a lovely vice which rotates and has a small anvil on the back which would be nice if I find that style cheap enough.

I have to ask (although I doubt I'll need them) what are the dog holes about? Now seeing them in that build I realize what the holes in my workmate are called.

Attachments

Love the music in "The English Woodworker" and that explains it very well and even more! GLFaria, thankyou for the picture too, my workmate is missing all of the bench-dogs, however I think I vaguely remember my Dads other workmate having them.

I won't be cutting dogs holes into my bench as I'm merely learning woodworking skills to build the bench then I'll mainly be fiddling with my bike, RC car or the likes on top.

I have this afternoon had a toy about with lap and M&T joints with varying degrees of success. Firstly, I need more time to play about, I was in a bit of a rush.

I have cut my front beams to length (72") and cut a lap joint into 1 end which apart from a lightly rough finish (added texture for glue!) I'm fairly happy with. My downside seems to be my old fence posts for legs, I'm finding it hard to cut them square as my mitre saw isn't big enough to cope with them and even if I do cut them square I'm fairly sure there slightly warped.

My 1 chisel is as blunt as I remember but it's only about 15mm wide so was ideal for trying to cut a mortice.

I took advice from an austratian bench builder on youtube and used my circular saw to make several cuts to the correct depth to make knocking out the waste a little easier, although I could do with a plane or wider chisel to make the surface a smoother finish.

I'll put some pics up after I've had my dinner.

I'm unsure at this stage weather to continue with the fence posts legs or buy some new 4x4" as it stands I don't think I'll have enough fence post for all 4 corners as the bottoms were rotted further up than I expected, leaving me having to trim the length down considerably.

I won't be cutting dogs holes into my bench as I'm merely learning woodworking skills to build the bench then I'll mainly be fiddling with my bike, RC car or the likes on top.

I have this afternoon had a toy about with lap and M&T joints with varying degrees of success. Firstly, I need more time to play about, I was in a bit of a rush.

I have cut my front beams to length (72") and cut a lap joint into 1 end which apart from a lightly rough finish (added texture for glue!) I'm fairly happy with. My downside seems to be my old fence posts for legs, I'm finding it hard to cut them square as my mitre saw isn't big enough to cope with them and even if I do cut them square I'm fairly sure there slightly warped.

My 1 chisel is as blunt as I remember but it's only about 15mm wide so was ideal for trying to cut a mortice.

I took advice from an austratian bench builder on youtube and used my circular saw to make several cuts to the correct depth to make knocking out the waste a little easier, although I could do with a plane or wider chisel to make the surface a smoother finish.

I'll put some pics up after I've had my dinner.

I'm unsure at this stage weather to continue with the fence posts legs or buy some new 4x4" as it stands I don't think I'll have enough fence post for all 4 corners as the bottoms were rotted further up than I expected, leaving me having to trim the length down considerably.

Ok then, set your expressions to cringe...

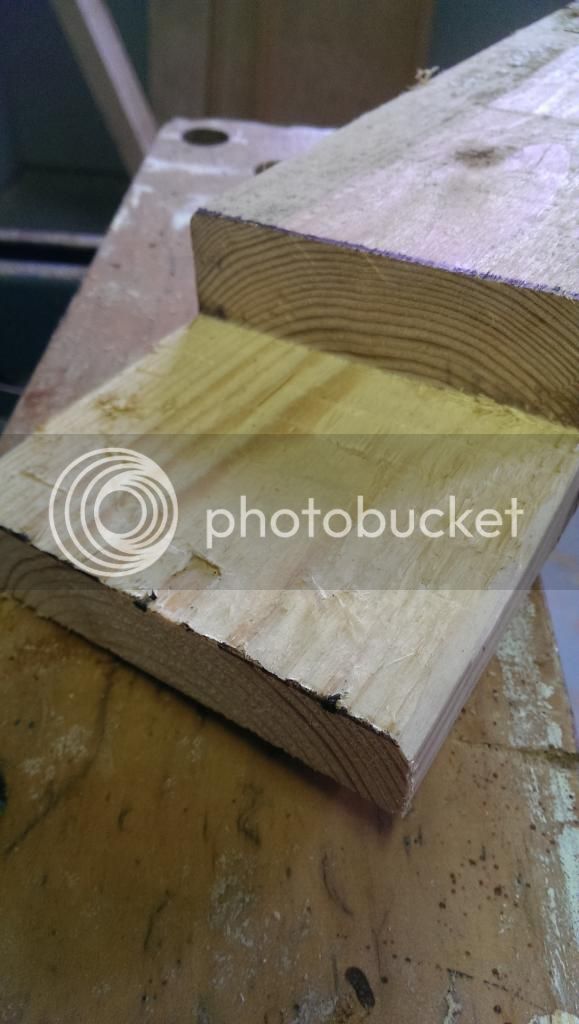

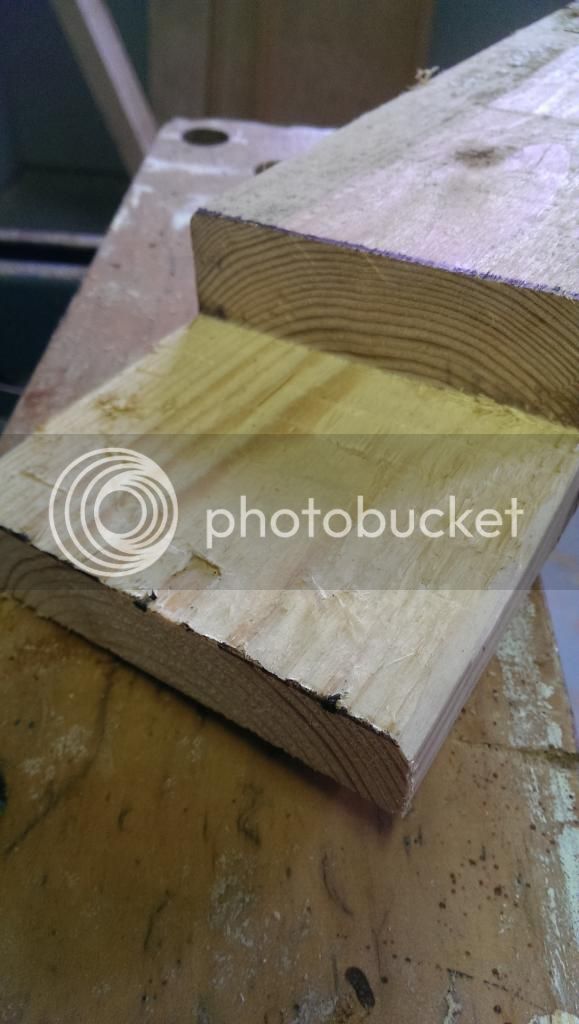

The start of my practice M&T. Lesson 1, don't drill all the way through as it causes major blow outs. Lesson 2, trying to make several shallow slits with a circular saw on such a narrow piece of wood proved inaccurate.

My lap joint with fence post and 4x2. Very happy with the 4x2 work but my cuts on the fence post aren't the greatest.

The start of my practice M&T. Lesson 1, don't drill all the way through as it causes major blow outs. Lesson 2, trying to make several shallow slits with a circular saw on such a narrow piece of wood proved inaccurate.

My lap joint with fence post and 4x2. Very happy with the 4x2 work but my cuts on the fence post aren't the greatest.

wcndave

Established Member

So it seems you are building a table rather than a workbench ;-)

I'm really not sure those lap joints are going to provide the stability that you'll need from a work bench.

My workbench thread is here:

wip-my-first-workbench-t68280.html

Lots of pics in there. I built something similar to a Paul Sellers workbench. As you can see the joints are pretty orrible, but once you've put the aprons on it gets very solid very quickly.

My workbench thread is here:

wip-my-first-workbench-t68280.html

Lots of pics in there. I built something similar to a Paul Sellers workbench. As you can see the joints are pretty orrible, but once you've put the aprons on it gets very solid very quickly.

wcndave

Established Member

That was my point

Also he's only going to use it for playing with cars and stuff, so really he wants to build a work table. which is fine. No hand planing boards flat.

Also he's only going to use it for playing with cars and stuff, so really he wants to build a work table. which is fine. No hand planing boards flat.

bugbear

Established Member

wcndave":1a2eljht said:That was my point

Also he's only going to use it for playing with cars and stuff, so really he wants to build a work table. which is fine. No hand planing boards flat.

In that case something like this?

Link:

http://www.buildeazy.com/workbench.html

No cut joints - at most you need semi accurate cross cutting.

And diagonal bracing to make it rigid.

Here's a full WIP:

http://www.hammerzone.com/archives/work ... w20xl.html

BugBear

Thanks for the help again, indeed once built I doubt I'll use a plane again for a long time.

I think by the time the rest of the joints are in place and the lap joints are screwed and glued it will be very sturdy, as I'll be putting a solid shelf at lower levels, most likely a cut to fit bit of chipboard onto M&T rails so there should be any movement downstairs, then I'll be putting a few cross braces on the end sections too.

Basically copying the design of my current bench which is nice and solid which was built 30 odd years ago.

I think by the time the rest of the joints are in place and the lap joints are screwed and glued it will be very sturdy, as I'll be putting a solid shelf at lower levels, most likely a cut to fit bit of chipboard onto M&T rails so there should be any movement downstairs, then I'll be putting a few cross braces on the end sections too.

Basically copying the design of my current bench which is nice and solid which was built 30 odd years ago.

So most of my morning has been spent watching Paul Sellers YouTube videos. After watching his methods the method I followed using a circular saw to "ease" waste removal on the tenon was foolish. However I used Paul's method to clean up the mess I had made and got it a bit tidier but most importantly, it fits tightly!

Yes, it's certainly not a square joint but considering I was marking up with a marker pen it's hardly surprising and every measuring device I had to had was so long and cumbersome.

So I have now dug out a 6" steel rule and using a biro instead from now on (couldn't find a pencil!)

Now first time round I grabbed the chisel and went for it, but this time I brought out the wet stone and got my chisel nice and sharp, what a difference!

I picked up a tenon saw from a freecycle group this morning, currently got my eye on a set square, chisel set and a wooden mallet from a local seller on ebay.

Yes, it's certainly not a square joint but considering I was marking up with a marker pen it's hardly surprising and every measuring device I had to had was so long and cumbersome.

So I have now dug out a 6" steel rule and using a biro instead from now on (couldn't find a pencil!)

Now first time round I grabbed the chisel and went for it, but this time I brought out the wet stone and got my chisel nice and sharp, what a difference!

I picked up a tenon saw from a freecycle group this morning, currently got my eye on a set square, chisel set and a wooden mallet from a local seller on ebay.

Cheers, that's what I figured. Practice makes perfect etc

Next time I get time in the workshop I'll be cutting the mortice without boring out most the waste with a drill first. It seems it would take less time cutting it completely with a chisel rather than boring with the drill then tidying up the mess, plus I imagine a completely chiselled mortice to be a fair bit neater.

Next time I get time in the workshop I'll be cutting the mortice without boring out most the waste with a drill first. It seems it would take less time cutting it completely with a chisel rather than boring with the drill then tidying up the mess, plus I imagine a completely chiselled mortice to be a fair bit neater.

wcndave

Established Member

Good luck with that ;-)

We'll see you back for the reversal later!

Sent from my GT-I9100 using Tapatalk

We'll see you back for the reversal later!

Sent from my GT-I9100 using Tapatalk

What reversal?

I've just treated myself to a set of 3 new chisels, the 2nd hand ones on ebay were rising quickly and there was no need for me to buy a set of 6.

I went for these- http://www.ebay.co.uk/itm/Draper-45865- ... 5d4c2a2d5a

Just need to pick up a square to help marking out then I'm ready to give another test joint a go, hopefully nice and straight this time!

I've just treated myself to a set of 3 new chisels, the 2nd hand ones on ebay were rising quickly and there was no need for me to buy a set of 6.

I went for these- http://www.ebay.co.uk/itm/Draper-45865- ... 5d4c2a2d5a

Just need to pick up a square to help marking out then I'm ready to give another test joint a go, hopefully nice and straight this time!

wcndave

Established Member

I think that you may find boring it and then truing up edges far easier than chiseling the whole think out. That's all.

Sent from my GT-I9100 using Tapatalk

Sent from my GT-I9100 using Tapatalk

Don't know about their quality, but can you effectively sharpen your chisels? Otherwise they will just be a set of steel objects (admittedly with handles...) which, if hammered strong enough, may help remove some irregular chunks of wood. You are sure to need to sharpen them more often than not, so better learn to before starting to use them.PAUL_TDI":26g4rwf0 said:What reversal?

I've just treated myself to a set of 3 new chisels, the 2nd hand ones on ebay were rising quickly and there was no need for me to buy a set of 6.

I went for these- http://www.ebay.co.uk/itm/Draper-45865- ... 5d4c2a2d5a

Just need to pick up a square to help marking out then I'm ready to give another test joint a go, hopefully nice and straight this time!

Cheers

G.

Ohhhh gotcha Dave, haha we'll soon find out!

No troubles sharpening them when they need it.

I'm quite a fan of Draper tools so they were the best make of the cheaper sets I could find. I have a very good big socket set which is Draper Expert and hasn't let me down yet.

No troubles sharpening them when they need it.

I'm quite a fan of Draper tools so they were the best make of the cheaper sets I could find. I have a very good big socket set which is Draper Expert and hasn't let me down yet.

So when you go to start building your workbench out of lovely reclaimed timber only to realize that its very twisted, now I'm sure a good carpenter could of made do with it and made adjustment to the joints, but I didn't want that problem to overcome.

So bought the cheapest wood I could find which happened to be fencing timber.

4 hours of labouring over the above has left me this....

I've also got the front upper and lower beams cut with joints, so will do the back ones then assemble front and rear frames.

And Dave, I'm pleased to say I knocked out the holes by hand. Well apart from drilling the odd 8mm hole through knots to get them out a bit easier.

I did go back to using the circular saw to cut lots of slots to the correct depth to make cutting out the lap and tenon joints easier, also saved time on marking out.

So bought the cheapest wood I could find which happened to be fencing timber.

4 hours of labouring over the above has left me this....

I've also got the front upper and lower beams cut with joints, so will do the back ones then assemble front and rear frames.

And Dave, I'm pleased to say I knocked out the holes by hand. Well apart from drilling the odd 8mm hole through knots to get them out a bit easier.

I did go back to using the circular saw to cut lots of slots to the correct depth to make cutting out the lap and tenon joints easier, also saved time on marking out.

I've never found hand held electrical tools much good at being accurate and when they're not going in quite the right direction things go wrong very quickly.

Marking is most important though and it's usually easier to get to the mark with hand tools IMHO.

TDI, would that be a 2 or 300?

Marking is most important though and it's usually easier to get to the mark with hand tools IMHO.

TDI, would that be a 2 or 300?

Similar threads

- Replies

- 23

- Views

- 2K

- Replies

- 23

- Views

- 2K

- Replies

- 44

- Views

- 3K

- Replies

- 102

- Views

- 7K