I was on pinterest the other day and saw a topic about stabilising log slices with 'peg'- polyethylene glycol.

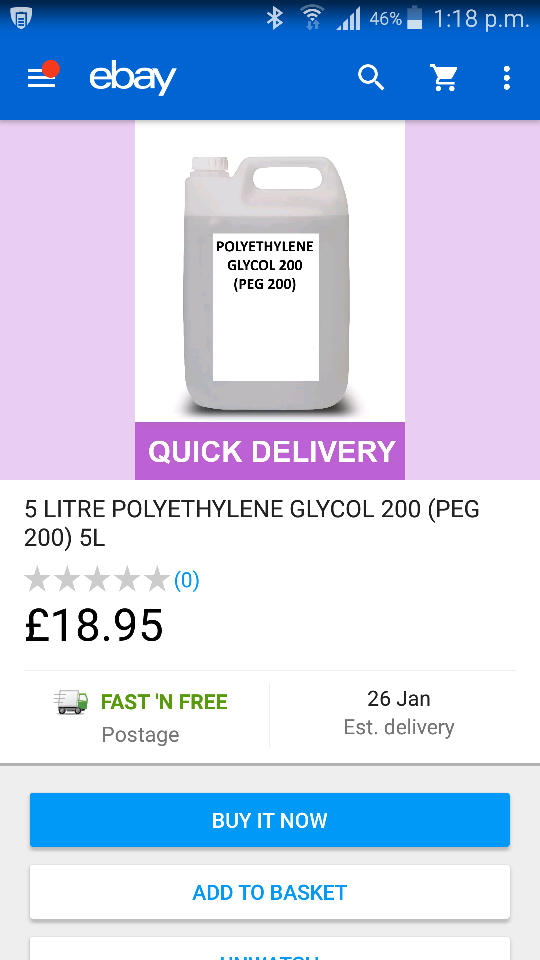

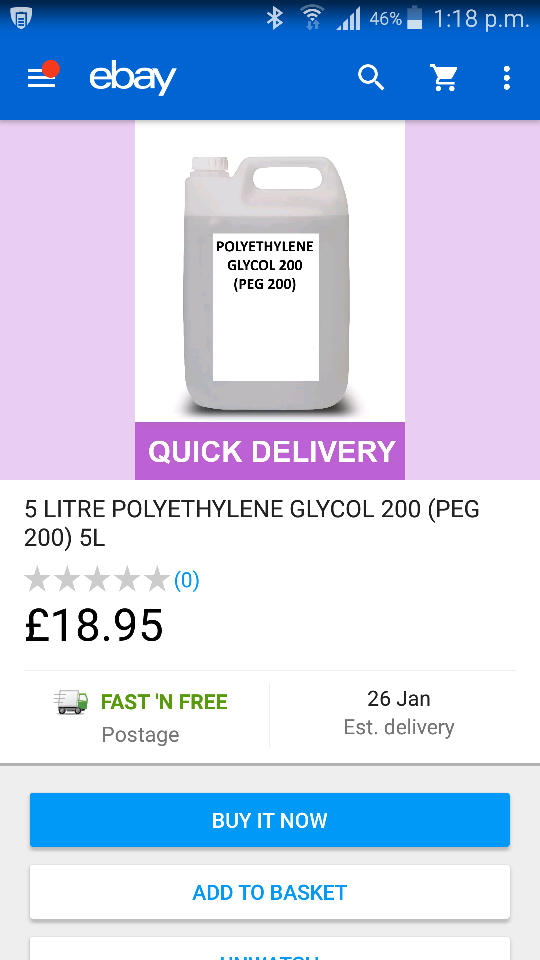

I was trying to find a cheap source and found 5 litres on ebay for £19.

Is this the right stuff ?

It seems rather cheap, so I'm thinking it's probably too good to be true.

I've got several logs I'm looking to cut into slices. It'd be good if I could somehow prevent them from drying/cracking as much.

Thanks

Coley

Sent from my SM-G900F using Tapatalk

I was trying to find a cheap source and found 5 litres on ebay for £19.

Is this the right stuff ?

It seems rather cheap, so I'm thinking it's probably too good to be true.

I've got several logs I'm looking to cut into slices. It'd be good if I could somehow prevent them from drying/cracking as much.

Thanks

Coley

Sent from my SM-G900F using Tapatalk