pollys13":33aeynpx said:

Thanks Peter. Did a bit more to the inside.

I found these old wooden g clamps ages ago. Riddled with worm holes, so I bagged them up and put them in the freezer- 6 weeks or so later, I remembered they were there. A couple big screws to the studwork and they seem quite sturdy.

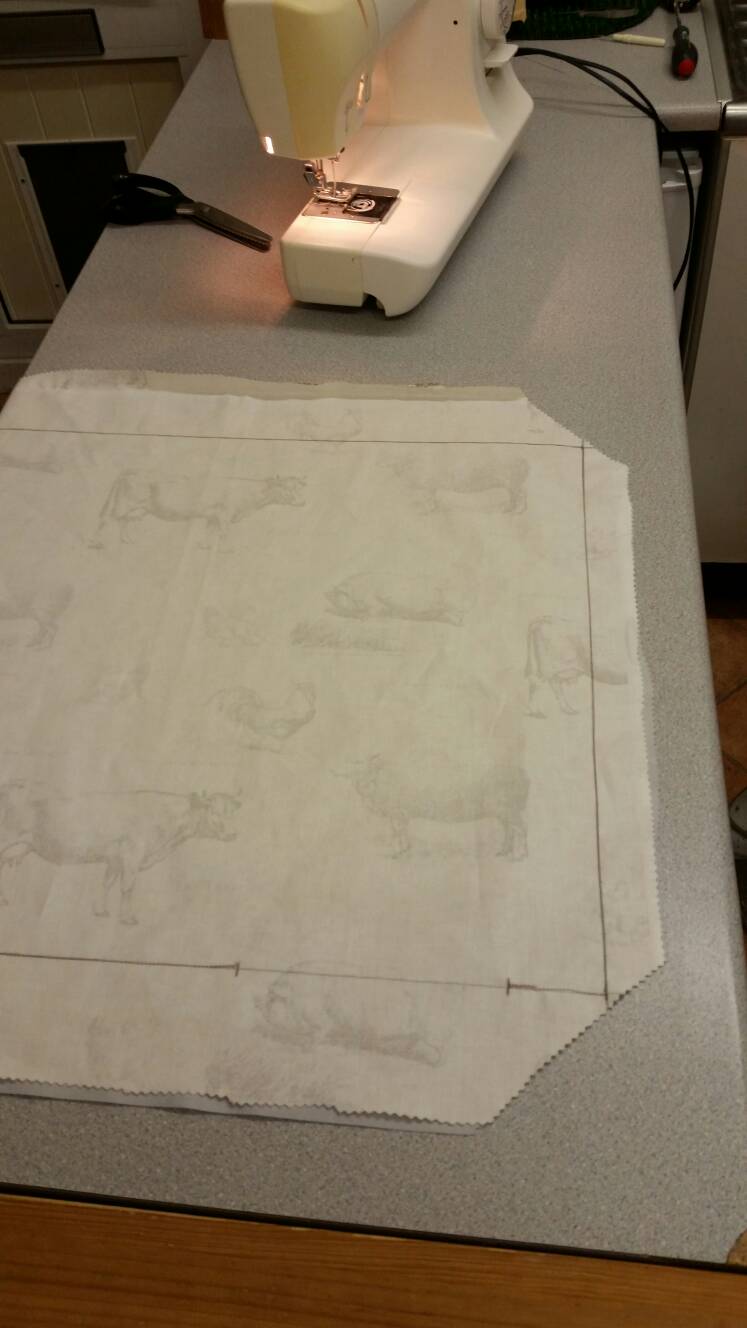

I got the Toyota out last night to make some curtains.

Didn't snap any needles last night, and got the foot to the floor on a few of the long runs [SMILING FACE WITH OPEN MOUTH]

I sew blackout fabric to the material and left 6 inchs so I could turn it inside out.

Punch some holes for the eyelets and used some rebar and shotgun cartridges for the pole/brackets

I really like the fabric despite my mate saying it looks hideous.

Last up is a small side table that's a very much work in progress.

Started off 170mm thick, planed down to 100mm - 3mm at a time.

Flattened roughly with the handplaner

Finished off on the thicknesser.

I wanted to get a finish on it asap, so oiled it within a couple hours. I oiled the bottom and was surprised when I looked out the other side

It had sucks it right through the other side in places !

It's under a pile of weights now with a piece of tin glued to the bottom to try and hold it together.

It appears the misery of having a part finished shed is over and now the fun part begins !!

Once the tables done, this corner needs sorting out next

I think it might look better putting the t.v in a cupboard. Sketchbook, cider with the curtains pulled tonight [SMILING FACE WITH OPEN MOUTH]

Coley

Sent from my SM-G900F using Tapatalk