twodoctors

Established Member

Hi all,

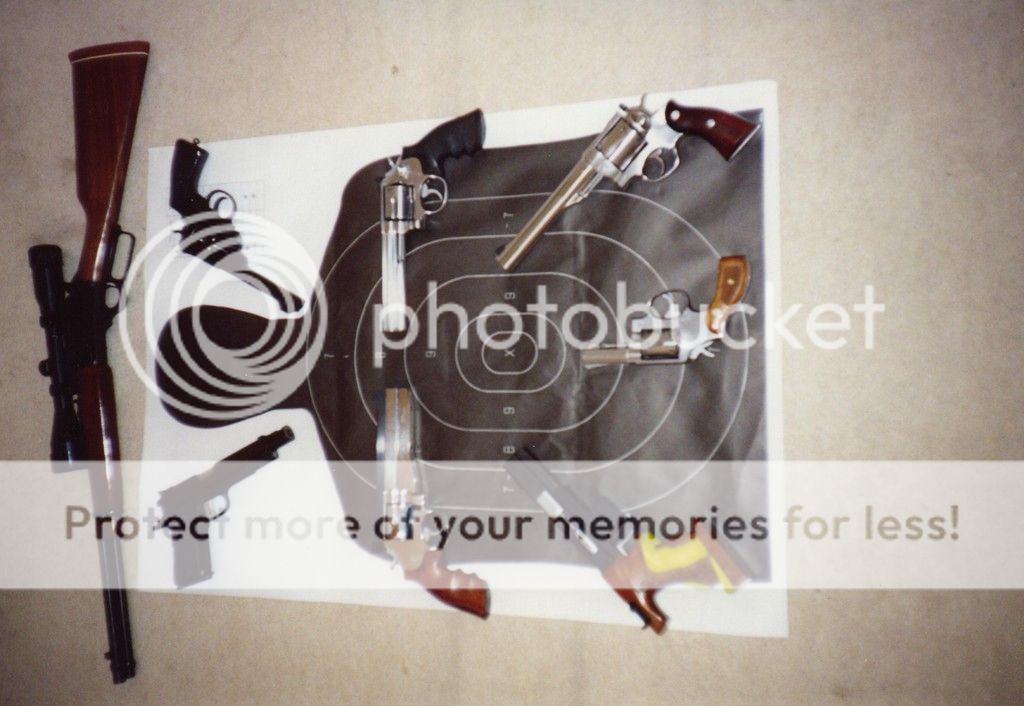

Going back to the original reason for getting back to woodworking, I am trying to make myself a target pistol grip... which essentially is a grip for a pistol with lots of contouring etc. A bit like what you would see in the Olympic.

With all the power tools that I've acquired, things are going a bit smoother than when I was wrestling with the handtools. However I am stuck again, trying to gouge out gaps within the piece for my fingers (the stage where a larger amount of material is removed before contouring with file/sanders. The thing don't think I can get a clean channel without using a router.

Router are not that expensive. The bits for it are though! What I would like to know is whether I need a router table as well. I am guessing I do as the piece I'm working with is not big (~120 x 70-ish), and the whatever jig the router has got won't workin in such small piece.

What kind of table should I look for. Any other tips?

Adrian

Going back to the original reason for getting back to woodworking, I am trying to make myself a target pistol grip... which essentially is a grip for a pistol with lots of contouring etc. A bit like what you would see in the Olympic.

With all the power tools that I've acquired, things are going a bit smoother than when I was wrestling with the handtools. However I am stuck again, trying to gouge out gaps within the piece for my fingers (the stage where a larger amount of material is removed before contouring with file/sanders. The thing don't think I can get a clean channel without using a router.

Router are not that expensive. The bits for it are though! What I would like to know is whether I need a router table as well. I am guessing I do as the piece I'm working with is not big (~120 x 70-ish), and the whatever jig the router has got won't workin in such small piece.

What kind of table should I look for. Any other tips?

Adrian