I am trying to make a box from 9mm MDF using rebate joints. I bought a 9mm straight cutter from Wealden a while ago and tried it today with a jig I made today and the 9mm cutter isn't quite wide enough.

When I measured the MDF it was actually 9.34mm.

I went to buy a bigger router cutter thinking 9.5mm would be the one but Wealden are out of stock.

I'm just wanting to make sure that 9.5mm is the one to go for or should I be using a 10mm cutter?

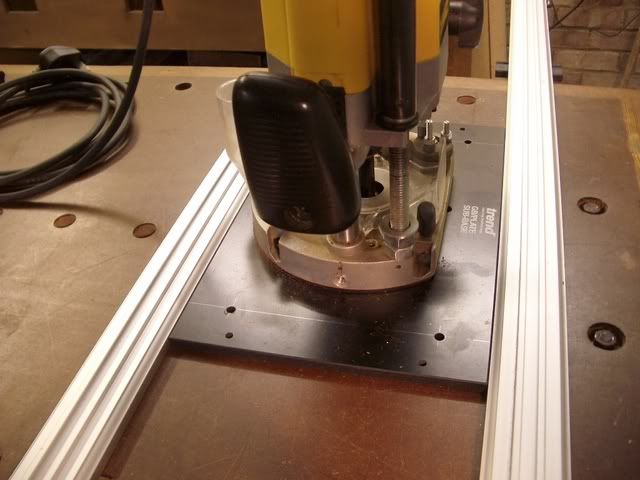

The jig I've made is similar to one that you would use for dadoes where the router runs between two straight edges so it can't waver off course. This means the router position is fixed so it will always cut in the same position so I can't adjust it like you would with a fence.

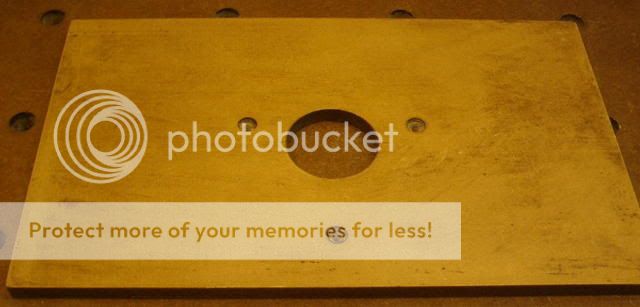

The wood I'm cutting is clamped so it's up against the middle block and I can then cut a rebate quickly and accurately. It cut brilliantly, just not wide enough for the MDF!

I'm loath to pay double the price to get a cutter from Trend so would prefer to buy from Wealden but want to make sure I buy the right size this time.

What do you think for cutter size?

Thanks,

Jennifer

When I measured the MDF it was actually 9.34mm.

I went to buy a bigger router cutter thinking 9.5mm would be the one but Wealden are out of stock.

I'm just wanting to make sure that 9.5mm is the one to go for or should I be using a 10mm cutter?

The jig I've made is similar to one that you would use for dadoes where the router runs between two straight edges so it can't waver off course. This means the router position is fixed so it will always cut in the same position so I can't adjust it like you would with a fence.

The wood I'm cutting is clamped so it's up against the middle block and I can then cut a rebate quickly and accurately. It cut brilliantly, just not wide enough for the MDF!

I'm loath to pay double the price to get a cutter from Trend so would prefer to buy from Wealden but want to make sure I buy the right size this time.

What do you think for cutter size?

Thanks,

Jennifer