slimshady

Established Member

Recently saw a Grand Designs (Milton Keynes 2014 Peter Berkin & Chard) where the "Aircraft builder" wanted a new Workshop with House attached. Correct thinking.

The Circular house was a single story timber frame, on concrete slab base, on an insulated formwork, on type1, on soil. No deep strip footings.

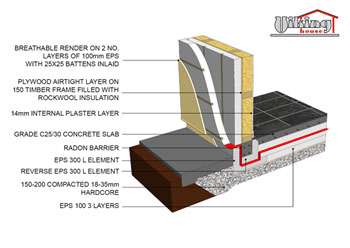

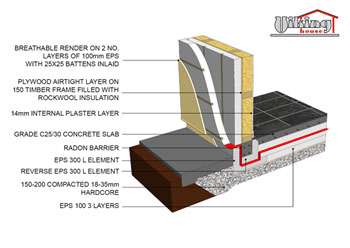

gives an impression of insulation size.

gives an impression of insulation size.

this cross section is closest to Oak frame with external insulation.

this cross section is closest to Oak frame with external insulation.

I'm working out a plan for 5.5 x 3 mtr super insulated Oak framed summerhouse / garden office / kids 'banished from house' type room.

Because I don't want to mix a load of concrete do you think I could use the Sill beams of my Oak frame to rest on the insulation directly. The 2nd picture shows the DPM in red, my plan would be same but with 6x6 oak sill beams and 6x6 oak floor joists (no concrete at all) , DPM and vapor barriers would envelope the whole building.

According to what I've read the 12" XPS insulation is waterproof, the DPM stopping anything anyway.

Questions I have are around the lack of any airflow under the building like with a normal shed, summerhouse. But then it is Oak and not tanalised.

Any input or thoughts from the collective.

Alex.

The Circular house was a single story timber frame, on concrete slab base, on an insulated formwork, on type1, on soil. No deep strip footings.

I'm working out a plan for 5.5 x 3 mtr super insulated Oak framed summerhouse / garden office / kids 'banished from house' type room.

Because I don't want to mix a load of concrete do you think I could use the Sill beams of my Oak frame to rest on the insulation directly. The 2nd picture shows the DPM in red, my plan would be same but with 6x6 oak sill beams and 6x6 oak floor joists (no concrete at all) , DPM and vapor barriers would envelope the whole building.

According to what I've read the 12" XPS insulation is waterproof, the DPM stopping anything anyway.

Questions I have are around the lack of any airflow under the building like with a normal shed, summerhouse. But then it is Oak and not tanalised.

Any input or thoughts from the collective.

Alex.