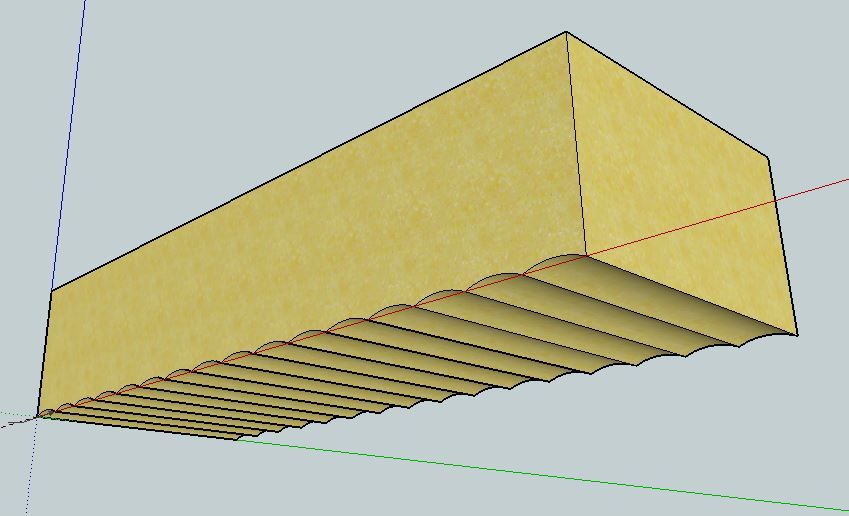

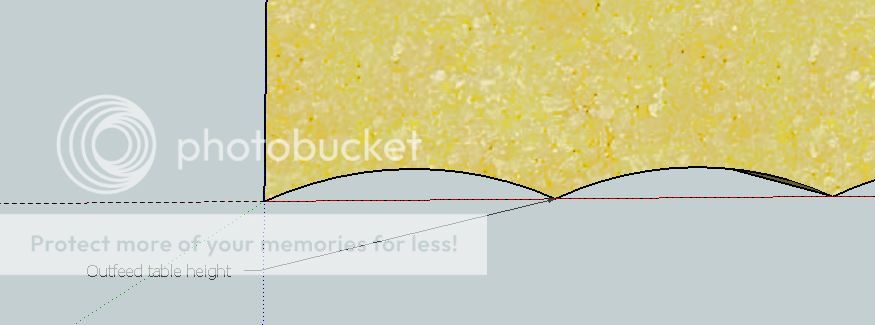

I seem to be getting quite bad snipe on my planer since changing blades. It didnt happen before, so it suggests bad setup to me.

I have bought one of the oneway multi gauges, which should arrive tomorrow. That should eliminate having to try and set them using the drag method, and should give consistent results and a known measurement.

Assuming that cutter block is parallel to the outfeed table, what height above the outfeed table should the blades be?

I have bought one of the oneway multi gauges, which should arrive tomorrow. That should eliminate having to try and set them using the drag method, and should give consistent results and a known measurement.

Assuming that cutter block is parallel to the outfeed table, what height above the outfeed table should the blades be?