eoinsgaff

Established Member

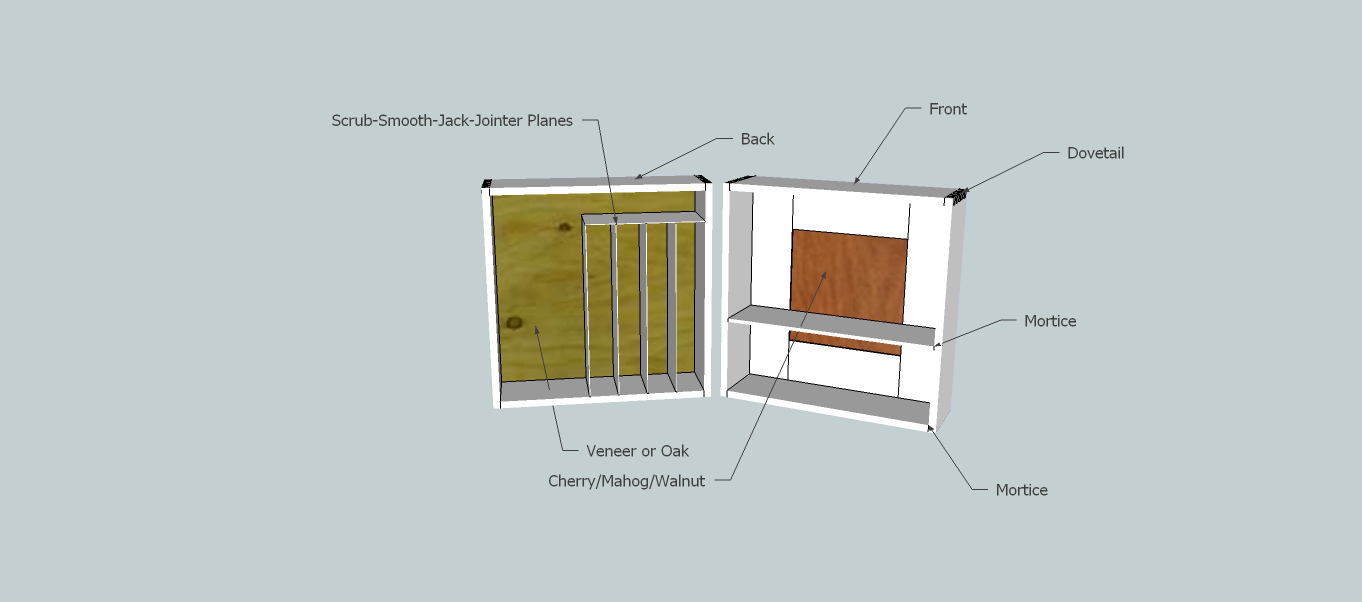

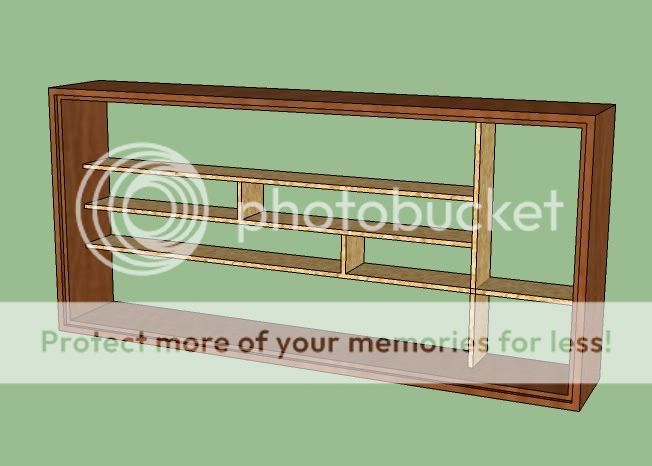

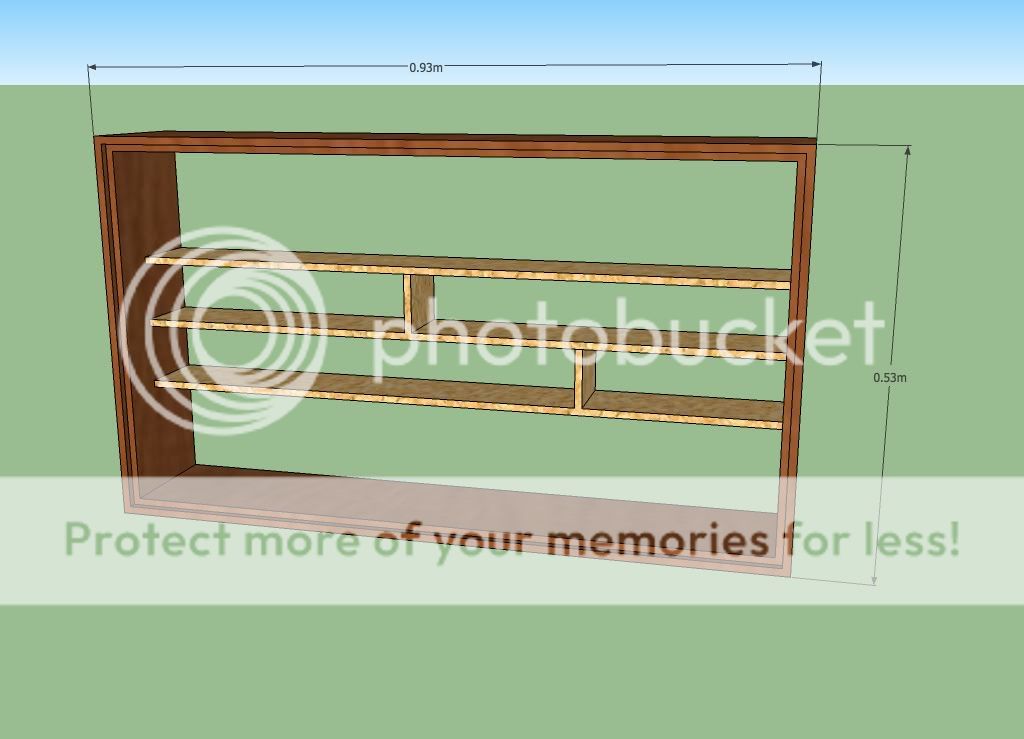

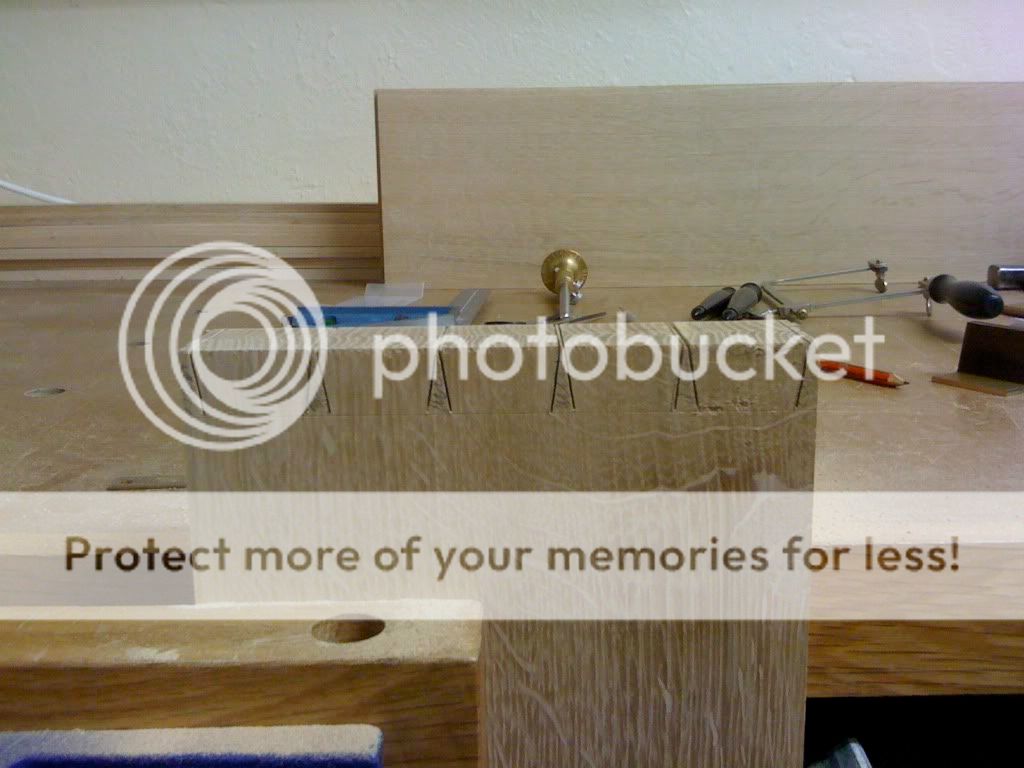

I'm planning a cabinet to store my planes over the coming months and I have a number of questions. I'll start with one first.

The primary purpose of this cabinet is to prevent rust. The planes are stored indoors but the house is very damp. I use various rust inhibitors but after a couple of hours use its easy to forget to reapply the wax or what ever.

I've heard of VCI rust inhibitors being used. Has anyone an idea if a VCI is available to spray onto a decorative felt or is there a similar approach I could consider.

One must appreciate the difficulty of the conditions where I have my tools. I have a temporary plywood box, sealed pretty tight, plenty of silica gel packs in place and still the tools rust if they are not lathered with wax. Very frustrating...

The primary purpose of this cabinet is to prevent rust. The planes are stored indoors but the house is very damp. I use various rust inhibitors but after a couple of hours use its easy to forget to reapply the wax or what ever.

I've heard of VCI rust inhibitors being used. Has anyone an idea if a VCI is available to spray onto a decorative felt or is there a similar approach I could consider.

One must appreciate the difficulty of the conditions where I have my tools. I have a temporary plywood box, sealed pretty tight, plenty of silica gel packs in place and still the tools rust if they are not lathered with wax. Very frustrating...