big soft moose

Established Member

- Joined

- 22 May 2008

- Messages

- 5,079

- Reaction score

- 0

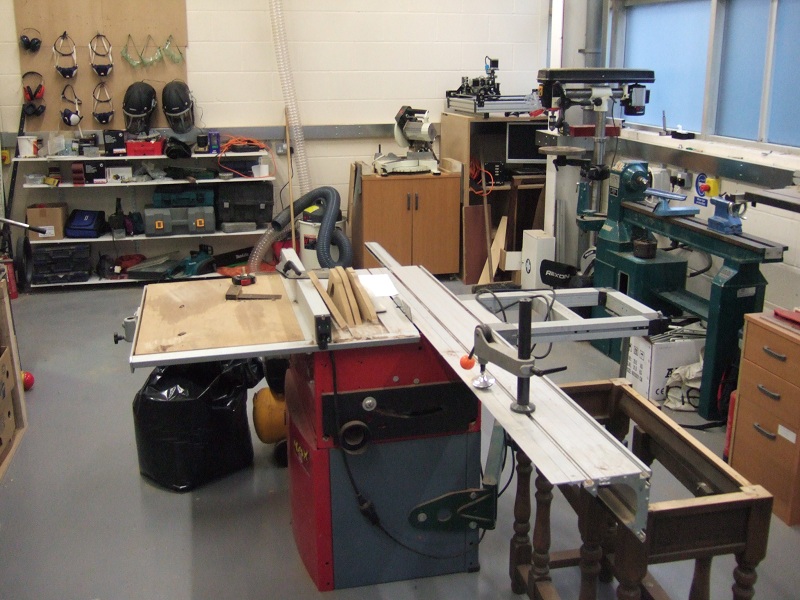

Just a quick tour round our new space (we moved in in july) - this is the 'shop at work rather than my own.

I'd note that it isnt quite finished - notably the DE isnt in yet (we are currently using a portable - but we do have a DX5000 we just have to run the ducting)

This is the veiw from one end

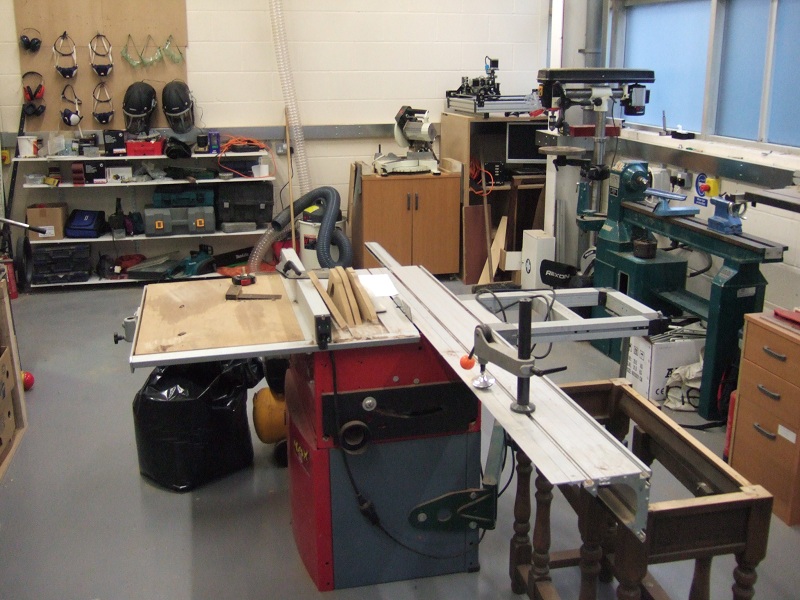

and from the other

The observant will notice that theres no crown guard on the tablesaw - we do have one, and it gets put on when in use - its just off when these were taken as we had only just finished measuring up for a replacement SUVA style one which is going to come down from the ceiling

Router table

The phone isnt usually on it

Morticer

a sedgie 571 wired into a 16 amp supply - it kept tripping the 13 A circuit on start up - its got an inch chisel in and is largely used for morticing sign posts

Our SCMS on its wheeled base - this has drop down support tables at both sides - on those brackets richard findley recomended from screwfix - behind it is the cnc rig a a Z90P from Routout CNC ltd

The axminster radial pillar drill, the viceroy lathe (those who cameb to miles bashe will have seen this in person - its too low and needs raising on a plinth - and our axminster bandsaw , currently U/S with a dead NVR

THe hand tools bench aka dumping ground - this is built out of stuff found in skips asnd wood recycled out of sign boards - no expense spent. NO vices fitted as yet but there are two sitting on top of it waiting to go on - note also the saw and 'mer board on the pillar to the right

and finally the wadkin planer - this is five years older than me - having originally been built in '68 - but it was fully refurbished and converted to single phase by the joinery company we got it from

Its a decent space, (and a big improvement on our last shop ) but it has to be as there are usually two or three of us working in here at once - tho we do have overspoil space in the main warehouse space outside the doors.

Incidentally if anyone is wondering about security with all those windows, they have security film on so people cant see in, and there is a master blaster alarm system with both break glass detectors and PIRs and automatic police call out- plus all the heavy kit is bolted to the floor and everything is labeled with ourr postcode - also outside the windows there is a fenced compound with 8ft security fences and a padlocked gate with no climb paint on it.

I'd note that it isnt quite finished - notably the DE isnt in yet (we are currently using a portable - but we do have a DX5000 we just have to run the ducting)

This is the veiw from one end

and from the other

The observant will notice that theres no crown guard on the tablesaw - we do have one, and it gets put on when in use - its just off when these were taken as we had only just finished measuring up for a replacement SUVA style one which is going to come down from the ceiling

Router table

The phone isnt usually on it

Morticer

a sedgie 571 wired into a 16 amp supply - it kept tripping the 13 A circuit on start up - its got an inch chisel in and is largely used for morticing sign posts

Our SCMS on its wheeled base - this has drop down support tables at both sides - on those brackets richard findley recomended from screwfix - behind it is the cnc rig a a Z90P from Routout CNC ltd

The axminster radial pillar drill, the viceroy lathe (those who cameb to miles bashe will have seen this in person - its too low and needs raising on a plinth - and our axminster bandsaw , currently U/S with a dead NVR

THe hand tools bench aka dumping ground - this is built out of stuff found in skips asnd wood recycled out of sign boards - no expense spent. NO vices fitted as yet but there are two sitting on top of it waiting to go on - note also the saw and 'mer board on the pillar to the right

and finally the wadkin planer - this is five years older than me - having originally been built in '68 - but it was fully refurbished and converted to single phase by the joinery company we got it from

Its a decent space, (and a big improvement on our last shop ) but it has to be as there are usually two or three of us working in here at once - tho we do have overspoil space in the main warehouse space outside the doors.

Incidentally if anyone is wondering about security with all those windows, they have security film on so people cant see in, and there is a master blaster alarm system with both break glass detectors and PIRs and automatic police call out- plus all the heavy kit is bolted to the floor and everything is labeled with ourr postcode - also outside the windows there is a fenced compound with 8ft security fences and a padlocked gate with no climb paint on it.