bluezephyr

Established Member

Ive used An Omec 750 auto dovetailer and i think theyre the dogs todger when it comes to production dovetailers, Before that all i had to use was a hand router bench jig combo which was a real pain when you have 40+ drawers to get done, Its what i use now and am desperately trying to find a secondhand Omec or similar to give my hands a break from all the vibration!.

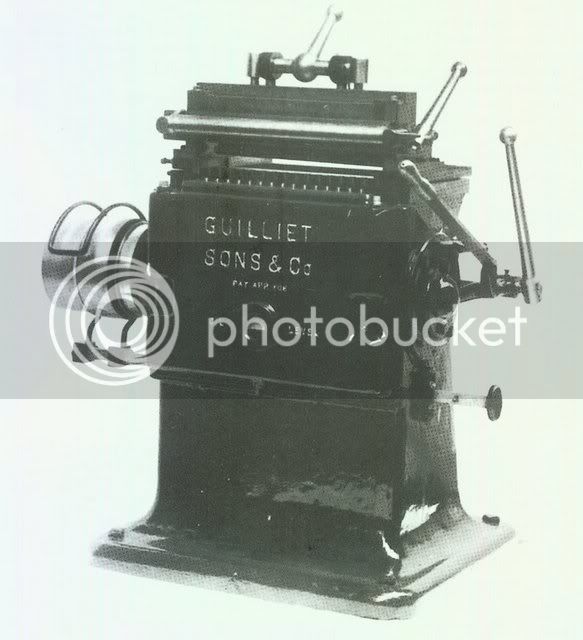

I keep seeing brookman Dovetailers for sale, These seem to be a proper cabinet makers tool, Big solid machine looks like it will chomp through the hardest of woods with ease, But ive never seen one working, Is the operation similar to the omec as far as clamping the wood is concerned? I realise with the multiple pins, its just one operation and it cuts the dovetails all in one go, where as the omec works its way up the machine and also gives time (if youre quick) to mess about with something else at the same time.

So. Omec or Brookman for longterm investment? or is there something else?

Thanks for reading

Tony

I keep seeing brookman Dovetailers for sale, These seem to be a proper cabinet makers tool, Big solid machine looks like it will chomp through the hardest of woods with ease, But ive never seen one working, Is the operation similar to the omec as far as clamping the wood is concerned? I realise with the multiple pins, its just one operation and it cuts the dovetails all in one go, where as the omec works its way up the machine and also gives time (if youre quick) to mess about with something else at the same time.

So. Omec or Brookman for longterm investment? or is there something else?

Thanks for reading

Tony