jorgoz

Established Member

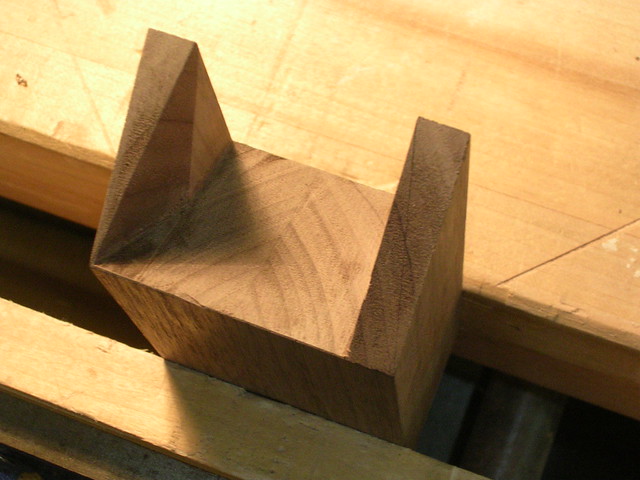

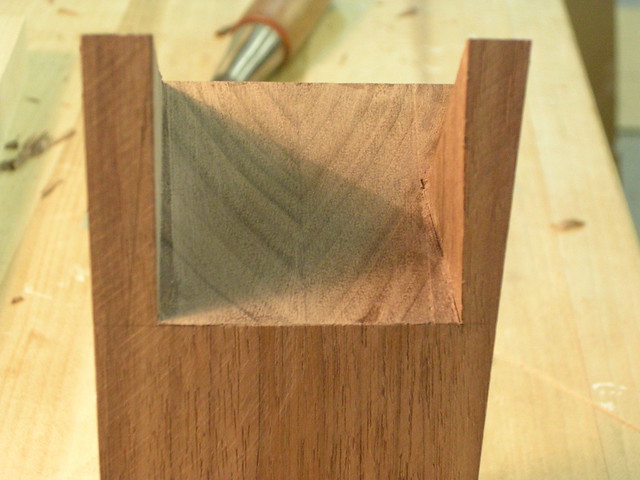

Started on my next plane build.

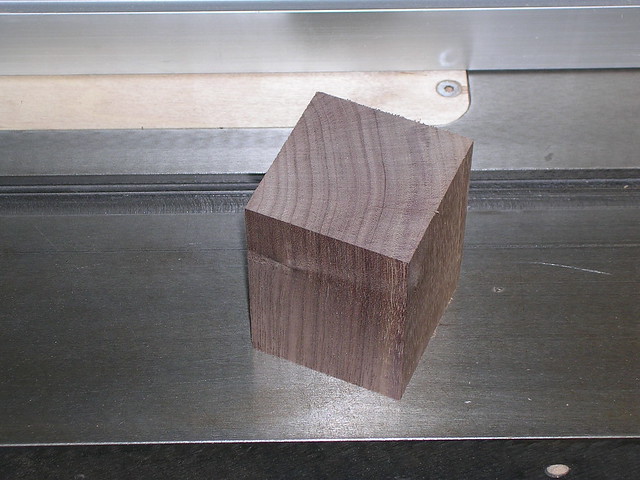

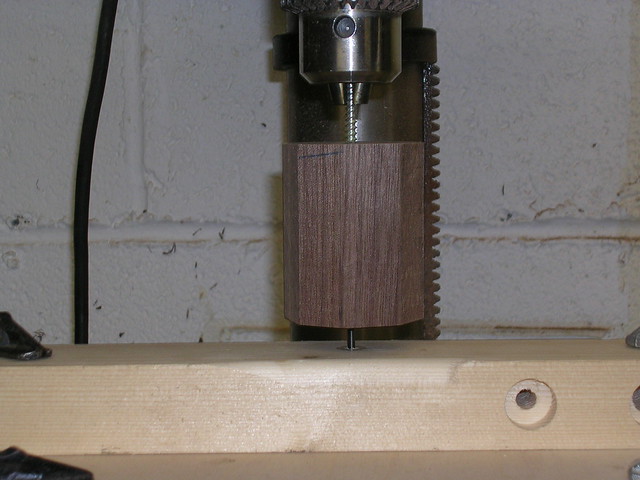

It's going to be a 4 1/2 type of plane, made of a walnut body with a hickory sole.

I started with the fun part first and made the tote.

I'm toying with the idea of adding lead to the main block for that extra bit of weight.

It's going to be a 4 1/2 type of plane, made of a walnut body with a hickory sole.

I started with the fun part first and made the tote.

I'm toying with the idea of adding lead to the main block for that extra bit of weight.